Introduction

VK-TFS-009H is widely used in toothpaste, cosmetics, medicine and food industries.

The equipment has a high degree of automation, automatic loading, automatic color matching, automatic sealing, batch numbering, and automatic discharging. Using the internal heating method, the Swiss “LEISTER” hot air heater is used to blow hot air from the inner wall of the hose, thereby melting the plastic, and then marking and batch number. The indexing adopts precision cam indexing mechanism, and the positioning is accurate and stable. The main motor adopts frequency conversion speed regulation, users can adjust the running speed by themselves.

Sealing method: Hot air sealing

Applicable tube materials: Plastics tubes, laminated tubes

Speed: 40-60 Tubes/min

View VideoHot air tube filling sealing machine is a high-quality, high-performance liquid filling and sealing packaging machine. The machine has a series of functions such as automatic filling, sealing and discharging. The machine uses PLC program control, advanced touch-type human-machine interface, photoelectric automatic positioning and tracking, etc., which makes the overall operation simpler and more complete, and enables enterprises to improve production efficiency, reduce labor intensity, and improve the preferred equipment for packaging grades.

Parameter

| Name | VK-TFS-009H Automatic Plastic / Lami Tube Filler Sealer Machine |

| Production capacity | 40-60 pieces(Adjustable) |

| Filling capacity | 5-250ml(Adjustable) |

| Tube diameter | 15-50mm |

| Tube length | 50-220mm |

| Filling error | ≤ ± 0.5% |

| Motor power | Main motor 1.1kw, heat sealing power: 3kw |

| Working air pressure | 0.60MPa |

| Air consumption | Not less than 600L / min |

| Equipment weight | 750kg |

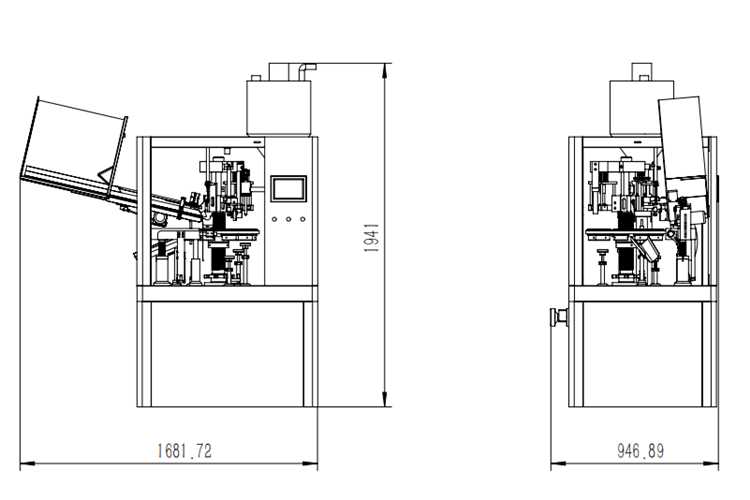

| Dimensions | 1700 * 1000 * 2000mm |

Working Video

Drawing

Features

1. The mechanical transmission part is enclosed below the platform, safe and reliable, no pollution;

2. The filling and sealing part is installed above the platform, and the semi-closed static-free outer frame visible cover is easy to observe, easy to operate, and easy to maintain;

3. Stainless steel operation panel surface, organic glass protective cover and installed door protection function;

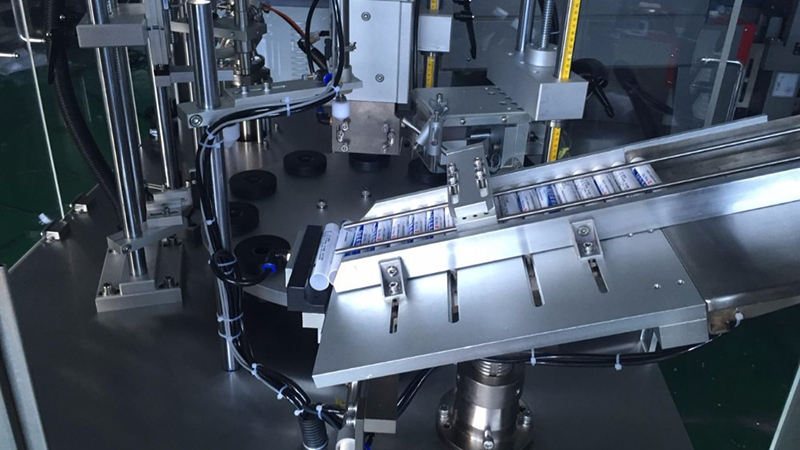

4. The oblique hanging tube warehouse can accommodate more hoses,

5. The upper tube device is equipped with a vacuum adsorption device. After the upper tube interacts with the pressure tube device, the hose is inserted into the upper tube station;

6. The photoelectric alignment station uses high-precision probes, stepper motors and other control hose patterns to be located in the correct position;

7. Without tube and no filling, the end of the injection, the air blowing device blows off the paste tail; anti-drawing, anti-drip filling

8. The heating temperature of the tail sealing adopts (Leister hot air gun) internal heating of the tube tail, and the outside is equipped with a cooling and cooling device;

9. Automatically imprint the production batch number or date at the position required by the process while sealing the tail;

10. The waste cutting manipulator cuts the waste edge of the hose tail, right-angle, R-angle or arc and other special-shaped seals;

11. Fault protection, overload shutdown, water pressure protection, air pressure protection.

Auto Loading System

Brand: VKPAK

Material: Made of stainless steel 304, surface by plating

More durable and keep long time

Mark Sensor

Brand: Pannasonic

Original: Japan

Tube Orientation

(R · G · B) LED in high-precision mode, high resolution of R / G · B ratio of reflected light through high-resolution by using built-in 12bitA / D converter can achieve high resolution of 1 / 4,000 Accuracy judgment, determine the color of the color. But also can effectively detect the color around those with patterns and patterns such as film.

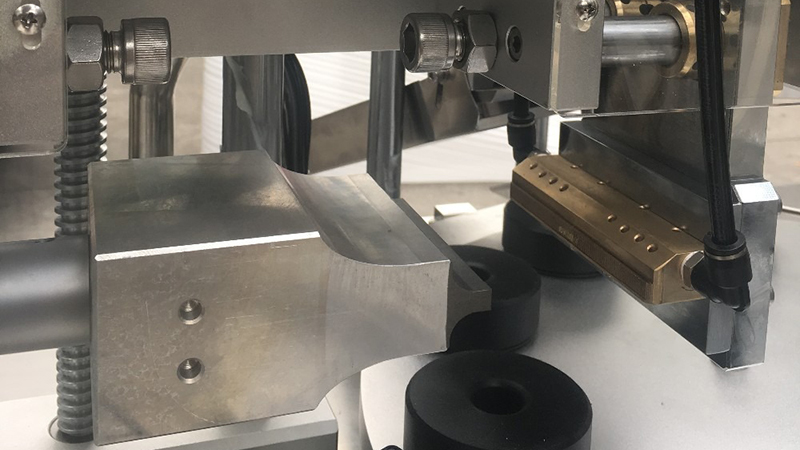

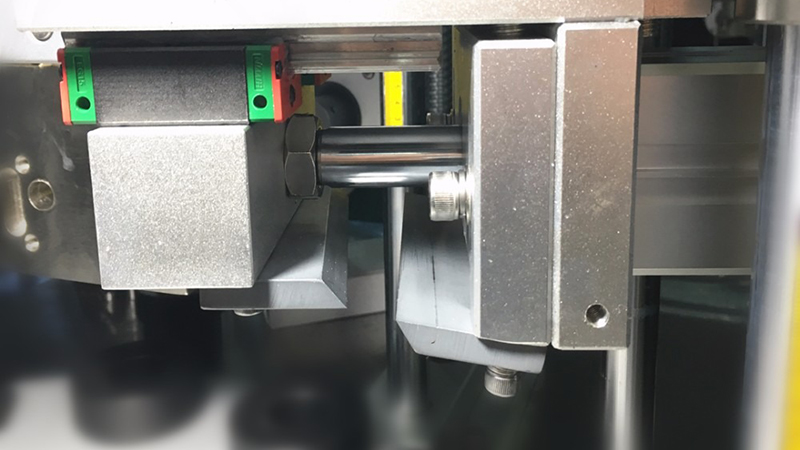

Sealing Horn

Two way sealing stations, can make the end of tubes sealing result are good and beautiful.

Brand: VKPAK

Made of aerospace aluminum

High precision

Sealing and Printing at the same time

Can be Filled date code ( Arabic numerals or English letter)

Free to change date code

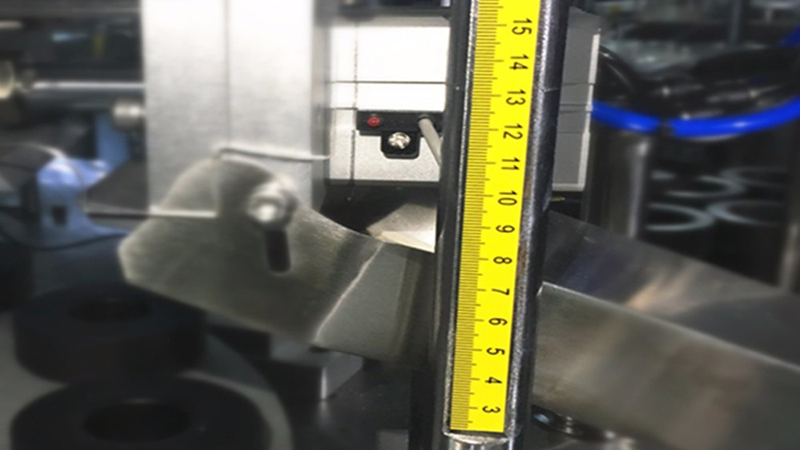

Dividing Rule

Assist to adjusting height of each working station according to tube size

Working Station

Qty: 10 working stations

Tube Holder Made by POM, more durable for using and changing

Two-way Cutter

For tube end trimming

Made by 304 stainless steel

No burrs after trimming

More durable

PLC Touch Screen

Brand: Weinview

Easy operation touch screen for quick setting.

| ITEMS | BRAND |

| PLC | DELTA |

| Frequency Changer | DELTA |

| Touch Screen | EVIEW |

| Encoder | Omron |

| Hot Air Generator | Leister |

| Thermometer MODE | DELTA |

| Proximity switch | SICK |

| Color Code Sensor | PANASONIC |

| Air Pressure Control System | Omron |

| Change Speed Motor | WANNAN |

| Main Pneumatic component | AIRTAC |

| Air-break switch | CHNT |

| Emergency Swift | Schneider |

| Power switch | Schneider |

| Power lock | Schneider |

| Power indicator | Schneider |

| Ac contactor | Schneider |

| Material Level Sensor | P+F |

| Material contact parts | 316L Stainless Steel |

| Machine Structure | 304 Stainless steel |

1. Original "SCHNEIDER" electrical components, and stability and durability guaranteed.

2. Built-in titanium tube water tank evaporator, avoid solid and other metal impurities.

3. Various models designed for different laser equipments. Water temperature tolerance at ±1℃(even±0.1℃) by precise digital control system. With push button operation, work normally without professional personnel.

4. Easy installation and compatible with equipments in any height.

5. High efficiency heat exchanger in special design, and static spraying casing with compact size.

| Technical parameters | |

| Power of compressor | 0.95KW |

| cooling capacity | 2.85KW |

| Pump power | 0.25KW |

| Refri gerant | R22 |

| Power supply | 1P-220V/50HZ |