Introduction

Absorbing foreign advanced technology is the foundation of producing bottle unscramble machine. It is developed and researched according to the requirement of high speed direction and this machine is the leading equipment in domestic market.

The automatic bottle unscrambler is mainly suitable for the supporting use of large-scale high-speed production equipment. It has the functions of automatic feeding, automatic bottle handling and sorting, and is an indispensable equipment for high-speed production lines.

Having a reliable plastic bottle or container unscrambler is essential to maximize efficiencies and assure your containers are prepared for the next step in the packaging process. Using an unscrambler from VKPAK will make certain you have an unscrambler that is easy to understand, easy to operate and maintain, and will also provide years of trouble free production.

Model: VK-BU-LX

View VideoBottle unscrambler is the indispensable outfit for high-speed filling machine, bottles are fed into air conveyor in order with mechanical action, to satisfy the automatic operation of filler.

Advantage

- Suitable for plastic bottles

- Different bottles can be applied by changing bottle moulds

- It will not damage the plastic bottles

- PLC control and touch screen

- If any fault, bottle unscrambler will automatically stop

- Bottle lifting will be applied

- The direction of bottle lifting can be various

- It can be connected with filling machine by air conveyor

- The appliances used in the machine are branded products

Specification

| No | Item | VK-BS |

| 1 | Size | Φ2400×1900mm |

| 2 | Speed | 4000-5000bph |

| 3 | Air Pressure | 0.7MPa |

| 4 | Air Consumption | 0.4M3/min |

| 5 | Applied Bottle | As requirement |

| 6 | POWER | 4.5KW |

| 7 | WEIGHT | 1.8T |

Configuration

| Parts | Model | Power | No. | Brand |

| Main Motor | YS7134 | 550W | 3 | Dacheng |

| Fan | DF-6 | 550/750W | 2 | Guantao |

| Motor | LCED18 | 40W | 2 | Zhongyi |

| Speed Adaptor | 5GU10KB | 40W | 1 | Zhongyi |

| Vibrator Motor | MIE | 30W | 1 | Guanlin |

| Convertor | VF200 | 750W | 3 | Panosonic |

| Sensor | 481/441 | Low Voltage | 3 | Panosonic |

| PLC | Panosonic | Low Voltage | 1 | Panosonic |

| Touch Screen | Weilun | Low Voltage | 1 | Weilun |

| Air Break | Schneider | 10-32A | 6 | Schneider |

| AC conductor | Schneider | Low Voltage | 2 | Schneider |

| Low Power | Schneider | Low Voltage | 1 | Schneider |

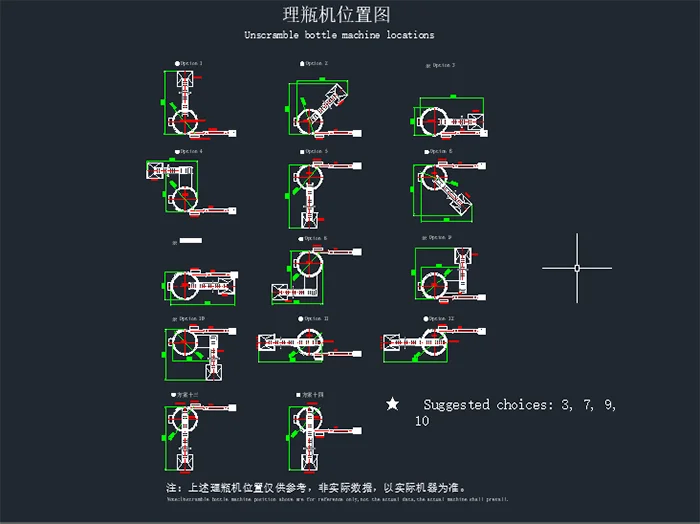

Automatic Bottle Unscrambler Machine Location

Features:

- The main motor speed reducer applies torque limit mechanism to avoid harming the machine when trouble happens.

- Twice push rowing bottle mechanism is used to ensure every bottle location has bottle which apparently prompts bottle output efficiency.

- Bottle handling air conveyor prevents bottles from dropping down when in transportation.

- Damaged bottles shall be rejected according to the reject mechanism.

- This machine is equipped with blocking bottle detector. It will stop and alarm when bottle blocks.

- No-bottle detector will send signal to elevator immediately when the bottle quantity is few and elevator shall supply bottles automatically.

- Photoelectric switch is installed on the air conveyor to control the unscramble machine.

- Bottle unscramble machine has oil mouths which make the gear, bearing and cam lubrication conveniently.

- Main electrical appliance (Inverter, PLC, Photoelectric switch, Relay) is from MITSUBISHI, OMRON, SIMENS and so on.