Introduction

This fully automatic liquid filling and capping machine is our company’s adaptation to market demand. It is mainly used for glass and plastic bottles such as round, square or shaped bottles, and introduces new products developed by foreign advanced technology. The machine adopts plunger type piston pump or peristaltic pump to perform filling, and is set with automatic upper cover, automatic screw cap, machine electrical integration, economical and practical, small footprint, widely used in pharmaceutical, pesticide, chemical, food, cosmetics Liquid packaging for other industries.

PLC control system, frequency control, high degree of automation. It is easy to adjust the loading capacity, and can adjust the filling amount of all metering pumps at one time, and can also make slight adjustments for each metering pump; the operation is simple and the adjustment is rapid. Filling needles are designed with anti-drip devices. When filled, they are submerged into the bottom of the bottle and slowly risen to prevent foaming. The whole machine is designed according to GMP requirements.

View VideoProduction capacity: 30-70 bottles/minute(Adjustable:Customized according to client needs)

Filling accuracy: ≥99%

Finished cap yield: ≥99%

Equipment power: 220V / 50Hz

Equipment power: 1.5KW

Equipment size: 2400*1500*1900mm

Applications: Eye drops, Creams, Essential Oil, CBD Oil, E-Liquid, E-Juice etc

1. Into the bottle: The bottles to be filled are placed manually into the conveyor belt.

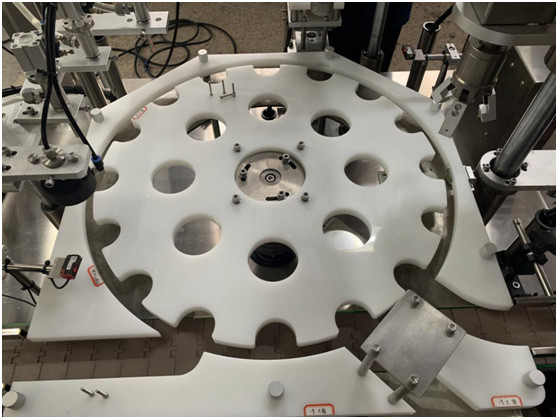

2. Detection: The photoelectric sensor detects whether there is an empty bottle on the main turntable. The detection signal is sent to the control computer to control the bottle filling, no bottle filling.

3. Filling: If a bottle is detected in front, the PLC controls the filling nozzle to rise into the bottle for quantitative filling.

4. Sprinkler cover: detect whether there is a bottle, swing arm type cover pre-rotation cover.

5. Screw cap: The servo motor controls the torque and speed to ensure that the cover is tight and the tightness is consistent

6. Out of the bottle: Finally, the bottle that has been screwed is out of the conveyor belt.

Operation Process

1. Material preparation: Ready enough bottles, plug in, cover, and liquid medicine, plug and cover should be full of vibration hopper rail and is located in the inside and outside cover location.

2. Feeder bottles: bottle feeder turntable make the bottles.

3. Filling: Bottle by oscillation tidy up the bottle opener for positioning disk thick, by positioning disk again intermittent drive to filling, stoppering, cover, screw cap. Solution by peristaltic pump suction by silicone pipe at the filling station again by the needle can be moved up and down automatically filling liquid in the bottle. The needle every move up and down, to complete a filling.

4. Plugging: Plug is provided by vibration hopper to stoppering station, bottle movement by wheel clearance to stoppering station, through the optical fiber detection to control stoppered cylinder solenoid valve work signal to control the cylinder work so as to achieve a bottle gasser no function, not stoppered bottle plug on plate using gravity principle design, avoid the spring or spring plate made before instability happens after long time, so the plug is very accurate.

5. Capping: Add good plug inside the bottle again by positioning disc sent to the affix, screw cap, affix a similar principle and urinating in principle, is done by the cylinder, covering various size by complete, constantly rotating screw LIDS below and overall do up and down, when the bottle stops right, decline of spin trapping modesty lid screw cover finish. Screw cap body adopts the design of constant torque, according to the bottle cap and bottle thread with torsion, to adjust the firmness of the screw cap after putting in place can automatic sliding, achieve the goal of not wounded cover not bottles.

6. Bottles out: Spin good cover bottle again by the bottle round to the conveyor belt pull final delivery outside the machine, and enter the next packaging process.

| No. | Descriptions | BRAND | ITEM | Remark (made in China) |

| 1 | Servo Motor | Panasonic | 0.45KW | Japan |

| 2 | Reducer | Fenghua | ATF1205-15 | Taiwan |

| 3 | Conveyor Motor | ZhenYu | YZ2-8024 | China |

| 4 | servo drivers | Panasonic | LXM 23DU15M3X | Japan |

| 5 | PLC | Siemens | TM218LDALCODR4PHN | German |

| 6 | Touch Screen | Siemens | HMZGXU3500 | German |

| 7 | Frequency Converter | Danfoss | ATV12H075M2 | |

| 8 | Photo electricity of Inspect bottle | OPTEX | BRF-N | Japan |

| 9 | Pneumatic Element | Airtac | Taiwan | |

| 10 | Rotary Valve | F07/F05 | No Need for Oil | |

| 11 | Pneumatic actuator | F07/F05 | No Need for Oil | |

| 12 | Low-Voltage Apparatus | Schneider | FRANCE | |

| 13 | proximity switch | ROKO | SC1204-N | Taiwan |

| 14 | Bearing | China | ||

| 15 | Lead Screw | TBI | Taiwan | |

| 16 | butterfly valve | CHZNA | china |