Introduction

Weigh filling machines, also known as net weight filling machines, are packaging machines that use scales to measure the exact amount of product dispensed into the container (VKPAK mainly offers weigh filling equipment for liquids). They are best for liquids filled in bulk quantities, such as 5-gallon pails, or products that have a very high value and thus need to be weighed correctly to avoid losing profit. Weigh filling machines are ideal filling solution due to their ease of automation, flexibility to handle multiple container sizes and varying product densities, and ability to maintain accuracy even with products containing entrapped air.

View VideoWeighing And Filling Machine Videos

20L Semi Automatic Explosion Proof Net Weight Filling Machine

Semi Auto Explosion Proof Two Head Epoxy Filling Machine

Automatic 5-30L Weighting Type Filling Machine

Automatic Lubricating Oil Pail Weighing Filling Line

Automatic 200L Drum Filling Machine

200L Automatic Open And Twist Cap Drum Filling Machine

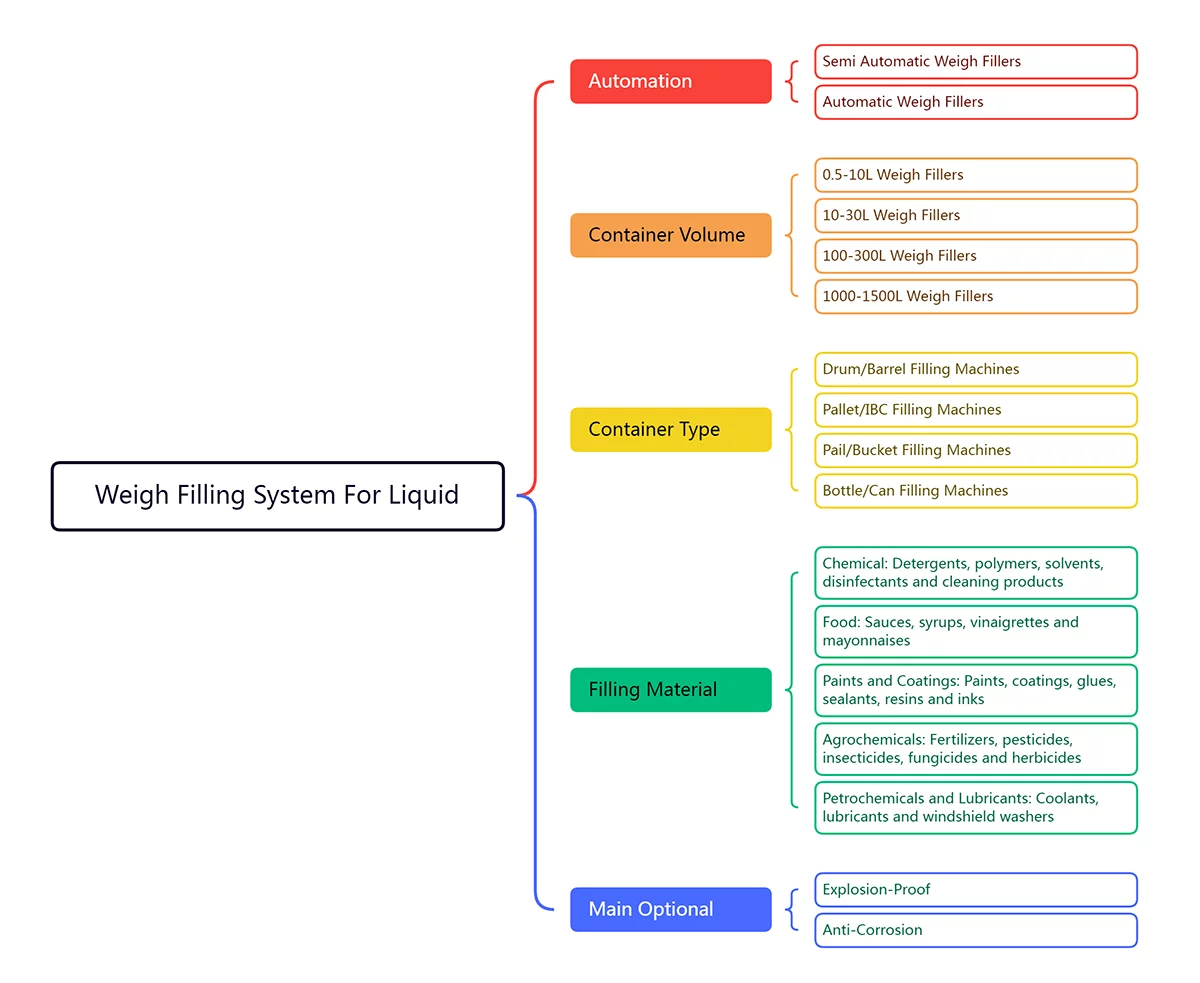

Types of Weighing And Filling Machines

Weighing liquid filling machines, according to different criteria can be divided into many different categories, such as automatic and semi-automatic, drum/pallet/pail/can weighing filling machine, chemical weigh fillers and food weight fillers etc.

The following chart lists the types of weighing and filling machines according to different criteria.

Semi Automatic VS Automatic Weight Filling Machine

Semi Auto Explosion-Proof Two-Head Epoxy Filling Machine

Automatic Net Weight Filling Machine

Container Volume

Weighing And Filling Machine Application Materials

At VKPAK, we offer a range of chemical filling machines that deliver consistent and precise results. Our portfolio includes turn-key and customized solutions designed to meet the specific needs of chemical manufacturers, whether they are building a new production line or upgrading their existing equipment.

Liquid Detergent Filling Machine

Bleach Filling Machine

One of the most significant challenges that chemical manufacturers face is filling containers of different sizes accurately. Overfilling can lead to unnecessary product wastage, while underfilling may cause customer dissatisfaction. A reliable filling machine, however, guarantees more precise fill rates for all types of chemicals processed.

Moreover, an efficient filling system can effectively handle liquids with varying levels of viscosity and acidity without clogging or spillage. Whether the liquid is highly viscous or watery, our chemical filling machines can accurately pump it at the desired rate and volume based on your operational requirements.

Chemical fluids that we handle include:

- Foaming chemicals

- Viscous liquids

- Aggressive liquids

- Flammable products

- Solvents

- Detergents

- Polymers

- Disinfectants

- Cleaning products

Customers select VKPAK for their chemical filling machine needs due to our versatility. Our filling machines can handle containers of all sizes including bottles, jerry cans, pails, drums and intermediate bulk containers (IBCs) that hold from 100ml up to 1,000L. Once the desired container is filled, your chemical products can then move to the automatic capping machinery to ensure a tight seal.

Our machines are capable of filling liquid foods in large containers such as drums and totes of 1000L or more, as well as smaller containers ranging from 50ml to 5L such as bottles, pails, and jerrycans. Moreover, we offer the flexibility to customize our food filling machines based on container types, material to be filled, and more.

Syrup Filling Machine

Sauce Filling Machine

Our weight-based filling technology ensures maximum accuracy in the filling process, and our explosion-proof designs provide an additional layer of safety. In addition, we offer options for smaller footprint machines that can be easily installed.

As a custom food packing machine supplier, we are committed to identifying and creating the exact right machine for your application and requirements. We work closely with our clients to deliver machines that are the ideal fit for their facilities and the job at hand.

At VKPAK, we conceptualize and build many types of custom food filling equipment, including sauce bottling equipment, syrup bottling equipment, mayonnaise bottling equipment, and more. Our machines are capable of filling and capping containers of nearly any size efficiently, ranging from 100ml to 1000L.

Let VKPAK design and engineer a customized food filling machine that meets the unique requirements of your liquid food products, whether you need to fill sauces, vinaigrettes, mayonnaises, syrups, or any other liquid food products.

We offer paint and coating filling equipment that can meet various paint filling specifications with two product lines tailored to different size needs. Our paint and coating filling machines are available in two categories:

- 50ml to 5L

- 5L and above

We have several machines within each category, and we offer different lidding and capping options, filling by weight for maximum accuracy, and monobloc machines that combine filling, capping, and labeling processes into one machine. We also provide small footprint options when space is a concern, explosion-proof construction for maximum safety, and flow control and smaller tanks for consistent flow, regardless of viscosity.

Paint Filling Machine

Our machines’ features and options are suitable for both fully automatic and semi-automatic paint and coating filling machines and can be customized to meet your specific needs.

Types of Paints Our Machines Can Fill

Let VKPAK conceptualize and build a customized paint filling/packing machine for your fluid or viscous products:

- Paints

- Glues

- Sealants

- Coatings

- Resins

- Inks

However, these chemicals can be extremely hazardous if they come into direct contact with skin or are inhaled. Therefore, manufacturers producing and packaging these chemicals must take precautions to ensure the safety of their employees and the end-users. An agrochemical filling machine is a crucial solution for manufacturers as it can accurately fill liquid agrochemical products of varying volumes and product inventory quantities while maintaining a high level of safety.

VKPAK Agrochemical Weighing Filling Machine Solutions

VKPAK specializes in providing liquid filling and capping machines for agrochemical manufacturers. Our machines are designed to meet the specific requirements of different types of liquid chemicals based on their characteristics.

We offer turn-key solutions to smaller agrochemical manufacturers who need to fill bottles, pails or jerrycans with liquid capacities of up to 100ml, as well as larger plant factories that use intermediate bulk containers (IBC) and drums with liquid capacities of up to 1000L.

Our team of experienced engineers and technicians can also assist with the design and manufacturing of specialized filling and capping equipment to meet unique production requirements. Whether you need a standalone pesticide filling machine or an inorganic fertilizer packaging machine that works in tandem with existing equipment, we can provide the ideal solution.

Pesticide Filling Machine

Here at VKPAK, we manage all of your liquid agrochemical needs by providing the right filling and capping equipment:

- Fertilizers

- Pesticides

- Herbicides

- Fungicides

- Insecticides

- Foaming chemicals

- Viscous liquids

- Aggressive liquids

- Flammable products

By integrating an agrochemical filling machine from VKPAK into your production processes, you can optimize your manufacturing runs and reduce the occurrence of filling errors and workplace accidents. Our state-of-the-art equipment is designed to enhance accuracy rates and minimize product wastage during weight-based filling, ensuring that containers are filled to the exact specifications without unnecessary overfilling.

Furthermore, our agrochemical liquid filling machine changeovers are highly efficient, thanks to our quick tooling solutions and streamlined machine interface, which simplifies the switching process between different containers or products. With our liquid and capping machines, you can maintain consistent levels of productivity without having to worry about changeover errors that could result in product loss, unplanned downtime, or hazardous agrochemical spills. Whether you require a semi-automatic pesticide filling machine or an automatic fertilizer packing machine, VKPAK offers cost-effective machine solutions to meet your needs.

At VKPAK, we offer filling machines and packaging equipment designed to help manufacturers achieve reliable and efficient supply chain operations. With a broad range of machines available, we enable you to fill and seal containers efficiently so that your products can be packaged and shipped to customers.

Brake Oil Filling Machine

Grease Filling Machine

Lubricant Filling Machine

Our filling and packaging machines are designed to provide optimal performance when weighing, filling, and sealing containers that hold petrochemicals and lubricants. The machine’s components are designed to operate smoothly, whether you’re working on short or large production runs or using large or small containers. Our filling, capping, and packaging machines are capable of handling a range of liquids based on their characteristics, including:

- Foaming chemicals

- Viscous liquids

- Aggressive liquids

- Flammable products

- Lubricants

- Windshield washers

- Coolants

VKPAK provides turn-key machinery options, offering a wide selection of machines so that you can add components and begin your processes immediately. If you require specialized filling equipment, our technicians and engineers will design and customize the right packaging machines to handle these liquids, including explosive products. Our lubricant oil filling machine can fill and cap various container types with capacities ranging from 100ml to 1,000L.

Choosing the right lube oil filling machine can have significant benefits throughout your production processes. Our machines complement existing operations, regardless of the container, specific lubricant, liquid petrochemical product, or company processes. A VKPAK packaging machine offers optimal functionality and accuracy rates, ensuring containers are filled to the correct capacity. With an automatic or semi-automatic oil filling machine, you can configure your operations to boost productivity and reach production goals.

Our machines feature a user-friendly interface that enables workers to make adjustments easily when switching product runs. They also provide quick tooling changeovers when switching to different container sizes, along with a customized cleaning program to maintain a safe environment and prolong the life of existing components.

VKPAK is a leading manufacturer and supplier of filling and capping machines. We provide customized packaging equipment, turn-key filling machine solutions, and upgrade equipment when your production processes change.

Weighing Filling Modes

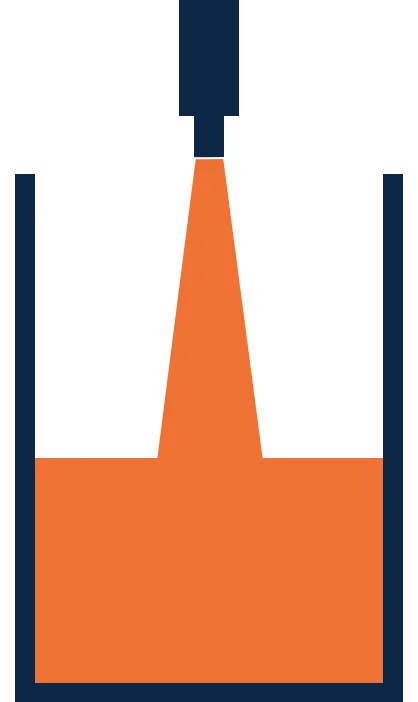

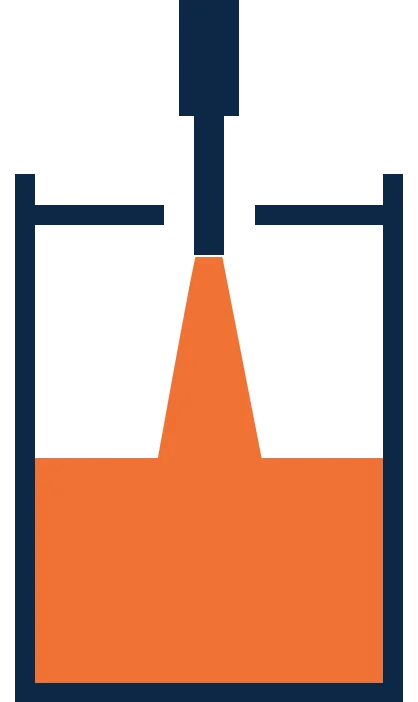

Your product's features and the container type determine the filling mode, filling mode can selected, either below-surface, below-bunghole or above-surface mode.

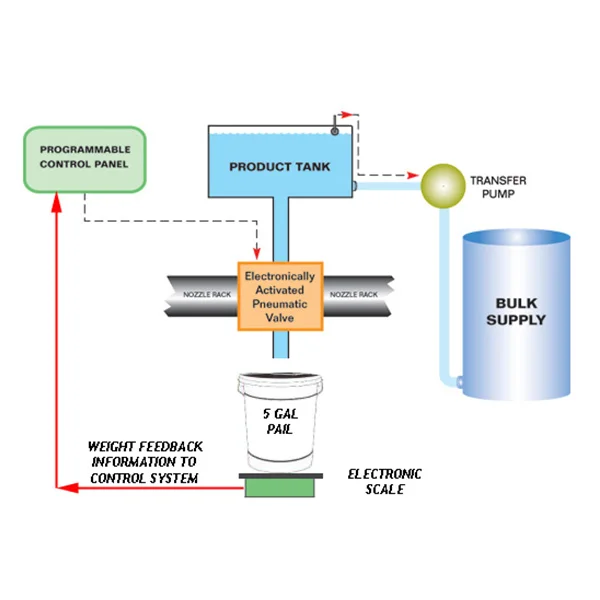

How Does A Net Weight Filler Work?

Understanding Weighing Filling Machine Product Delivery , Product Supply, Conveying Options And Filler Performance

For Direct Fill System (DFS) and Pressure Over Product (POP) delivery, maintaining consistent flow is less of a concern, as compared to manifold systems where consistent flow is crucial for optimal operation.

Gravity is the simplest means of supplying the filler, as it requires minimal equipment and can be easily controlled by closing a valve. However, the drawback of this method is that flow rates will vary during the filling cycle as the level in the supply tank reduces. This issue does not apply to DFS fillers, as flow rates are determined by the reservoir level, not feed pressure.

Air-operated double-diaphragm pumps (AODDs) are a cost-effective method of supplying a filler. However, surges from AODDs must be reduced when supplying a manifold system, and a pulsation dampener should be installed in such cases. To ensure effective operation, a valve must be installed immediately after the pulsation dampener to introduce backpressure. While the supply can be dead-headed, the filler will shut off air pressure to the pump to reduce backpressure and eliminate splatter when valves are opened. For DFS and POP systems, pulsation dampeners are not necessary.

Positive displacement pumps deliver a consistent flow to the filler, but they cannot be dead-headed. Therefore, it is recommended to include a recirculation line to avoid excessive wear and tear on the electric motors and address safety concerns. When flow to the filler stops, the pump can be stopped, and excess pressure is relieved through the recirculation line.

For non-free-flowing products, a hydraulic ram press can be used. This press uses hydraulic pressure to force a platen down into the supply tank, pressing the material out of the discharge valve and into the filler. To ensure optimal operation, the press should include a variable displacement hydraulic unit that allows the press to react to increased pressure during dribble and dead-head when the supply valve is shut.

To address this issue, a lateral transfer conveyor is implemented to reduce conveyor time for larger automatic lines. The lateral transfer conveyor consists of two parallel conveyors with the fill heads positioned in between. Containers are staged on the in-feed conveyor behind each fill head, and once full, all containers are transferred together onto the discharge conveyor. At the same time, the staged conveyors are moved under the fill heads, ready for the next cycle.

To prevent material from “sloshing” out of the container when accelerating from a full stop under the fill head to line speed, a variable-speed conveyor is employed. This feature is especially critical for open-top containers with low-viscosity materials and high fill levels, but sloshing can occur in any container with any type of material. The ability to adjust line speeds helps to ensure precise and accurate filling operations, enhancing the overall quality of the final product.

During the filling cycle, additional time-consuming operations can occur, which may impact performance. For automatic machines, the container must be isolated from vibrations caused by the moving conveyor, typically by lifting the scale to raise the container off the conveyor. In sub-surface filling, time is consumed as the lance travels to the bottom of the empty container and is removed from the filled container.

Delays may also be necessary before and after filling. Pre-fill, a slight delay may be imposed to ensure that the container is in place before opening the fill nozzle. Post-fill, delays may be required to allow the last of the product to drip from the nozzle or to get a final check-weight. Together with conveying, these non-filling operations can account for 40-70% of the total fill time.

While these operations may only represent a fraction of a second each, they can have a significant impact on performance. It is important to optimize each operation for maximum efficiency and accuracy. By understanding and carefully managing the variables and operations involved in the filling process, a high fill rate can be achieved while maintaining consistent accuracy and minimizing waste.

Reach out to VKPAK today to learn more about our weighing filling machines. Utilize our innovative technology, industry-specific knowledge and ability to handle any type of product — even explosive materials. We’ll help you design, commission and upgrade your custom packaging machines so you can increase your bottom line.