Introduction

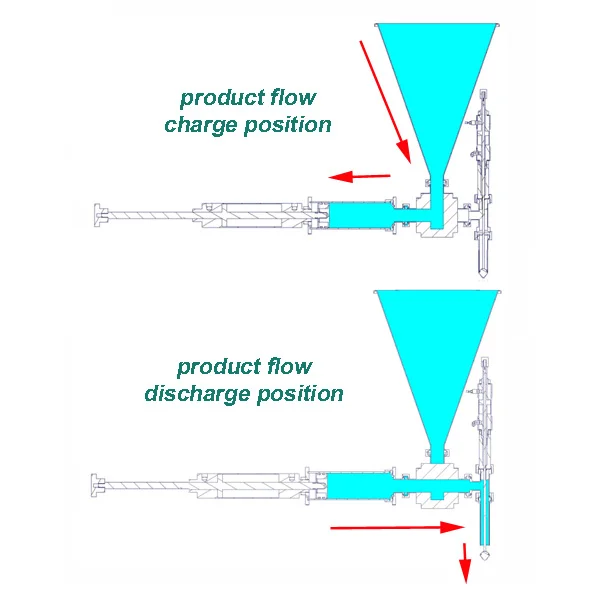

Piston fillers measure and dispense free flowing products – such as thin and/or moderately dense liquids – onto a container. Each machine is equipped with one or more volumetric pistons. Each fill/release cycle consists of an intake stroke, where the product is withdrawn from the container or hopper and taken into the product cylinder. The down stroke commences as soon as the product cylinder has reached its predetermined fill level. The piston pushes the product out of the cylinder and into the container.

Our piston fillers provide clean drip free depositing and adds precision in your product lines. We configured our piston fillers to deposit accurate amounts of sauces, stews, batters, meat/sauce mixtures, and pastes every single time. As a result, our piston fillers and depositors deliver the highest product fill accuracy, with the lowest level of product degradation in the industry.

Spills, drips, and container overflows may be common in food filling lines, but not when you use piston fillers from VKPAK. What’s more, your staff will have more time on their hands as our equipment doesn’t need looking after every minute of the day. We make sure our machines do as they should: Enhance your process so your workers can be free to perform other, more important tasks.

Model: VK-PF

View VideoThe VK-PF series volumetric filling system utilizes the delicate servo drive system to control the main filling structure, achieving high stability and precise positioning. With the vertical movement of the filling piston provides long term energy saving and also effectively reduces machine load rate.

2. Tool-Free Adjustment

Adjustments can be made through the PLC, completely tools-free, giving users a fast and efficient result. The delicate servo control system design provides options for surface layer liquid filling, bottom layer liquid filling, and bottle neck (opening) filling accordingly with different types of liquids.

3. High Accuracy

The delicate servo system controls the filling amount through precise piston strokes, providing high filling accuracy. The piston is intelligently designed with an adjusting mechanism to enable users to obtain ultimate higher accuracy.

4. High Adaptability

The Automatic Servo Filling Machine can be used in food, pharmaceuticals, chemicals, cosmetics, and other industries.

Parameter

| Nozzle Number (1-16 Heads) | PCS | 6 | 8 | 10 | 12 |

| Filling volume | Ml | 100-1000ml/ 250-2500ml/500-5000ml | |||

| Production capacity | Bottle/h | 1000-6000 pcs/Hour ( Depends on Filling volume) | |||

| Quantitative error | % | ≤±1% | |||

| Voltage | V | 380V/220V, 50Hz/60Hz | |||

| Power | KW | 2.5 | 2.5 | 2.5 | 2.5 |

| Air Pressure | MPA | 0.6-0.8 | |||

| Air consumption | M3/min | 0.8 | 1 | 1.2 | 1.2 |

Working Video

2. Adjustable filling speed

3. Accurate to ≤±1%

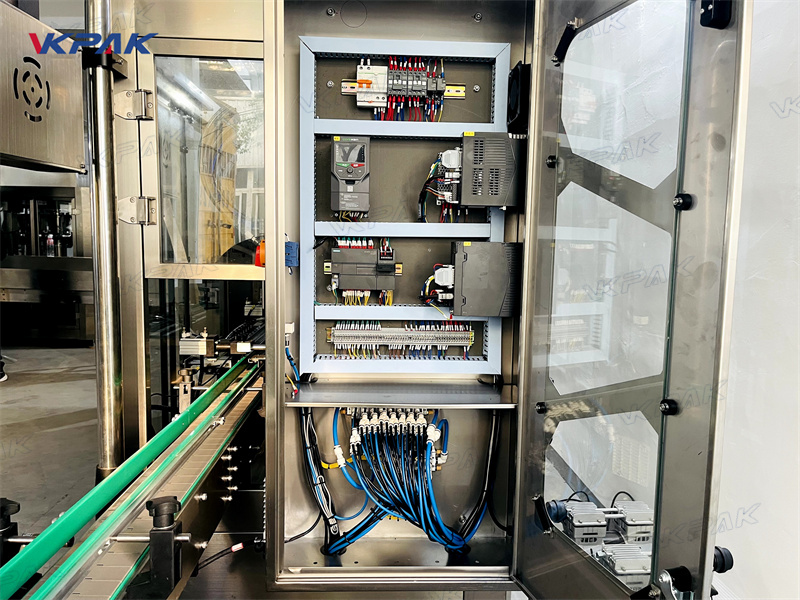

4. Integrated digital control with Schneider PLC and high-tech touch screen controls for easy operation.

5. Professional manufacturing techniques using the ISO-9001 system.

6. GMP standard stainless steel.

7. Bottom-up filling for option.

8. Bottle neck location.

9. No bottle-no fill system.

10. Filling zone protected by stainless steel frame

11. Volume is easily adjusted through touch screen. Filling pistons are controlled by servo system.

12. Individual piston adjustment.

13. Digital control system to enable multiple filling actions on the same bottle for double, triple and more.

14. Nozzles can set to be above bottle mouth or bottom up, synchronizing with liquid level (beneath or above) to eliminate bubbling of foamy liquids.

| Descriptions | BRAND |

| Servo Motor | Inovance |

| Servo Drivers | Inovance |

| PLC | Mitsubishi |

| Touch Screen | Siemens |

| Auxiliary Relay | OMRON |

| Air Cylinder | Airtac |

| Electromagnetic Valve | Airtac |

| Fibre Optic Sensor | SICK |

| Bottle Sensor | Keane |

| Frequency Transformer | Corkan |

Designed with swing arm touch screen control panel, this is more convenient to watch machine working status and adjust working data. Different kinds of operation language can be adjusted as production need.

The quantity of filling nozzles can be customized according to production need. Working height of filling nozzle can be adjusted according to bottle size. It is also equipped with anti-dripping tray, which can ensure production quality

Equipped with electric eye, which can detect passing by bottles and control the machine to work automatically.

Filling work is controlled by the piston pump, the rotary valve of piston pump can be customized as needed, ensures filling material with soft grains can be filled smoothly. The servo motor makes filling work more accurately and stably.