Introduction

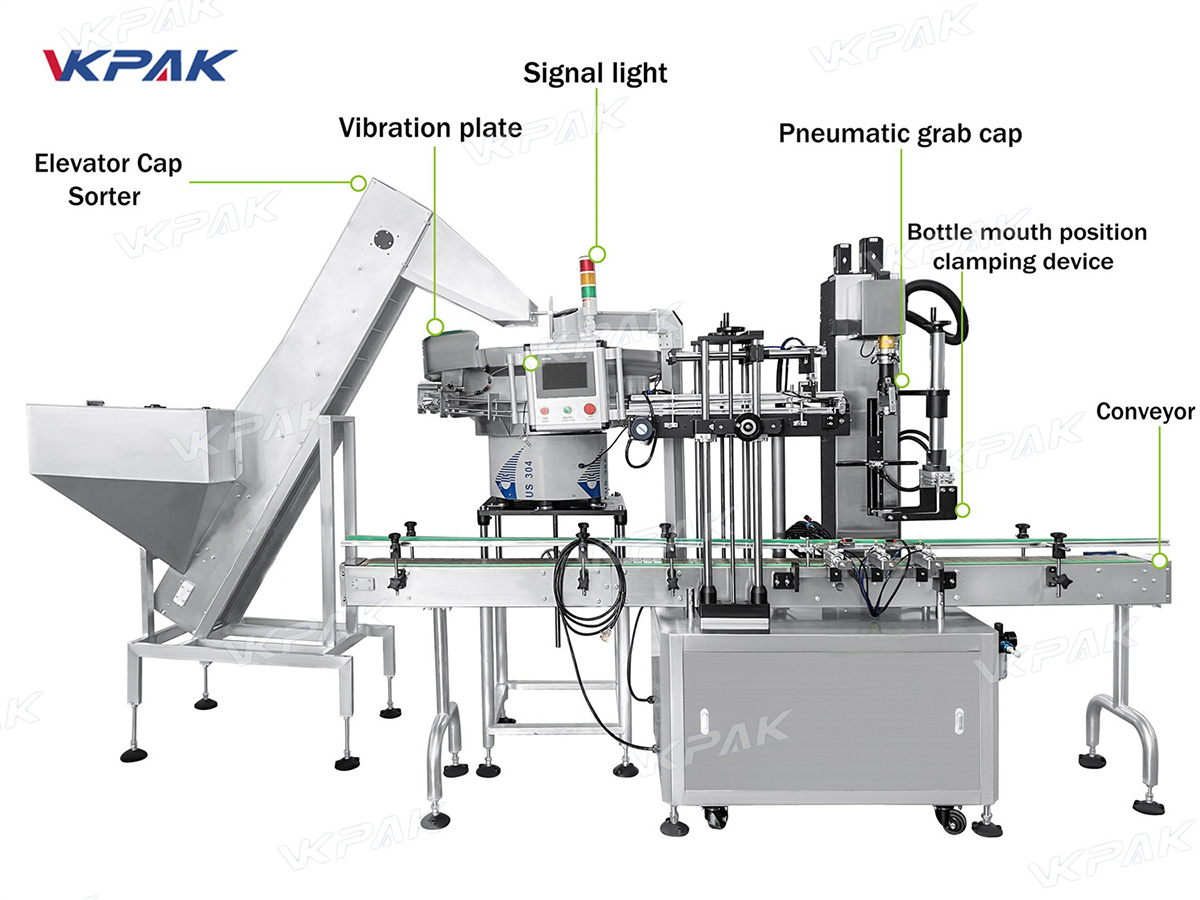

Some trigger pump caps are long and hard, so in the process of automated production, you may face difficulties in accurately placing the cap into the bottle. This cap feeding machine can mimic manually taking the cap and accurately placing it into the bottle. It can help you improve work efficiency and save a lot of labor costs. It can be connected to filling machines, capping machines and other machines to achieve complete packaging production work.

Designed for capping trigger pump spray caps with long and soft tubes, this machine has cap elevator to supply trigger pump caps in time. It can pass trigger pump caps and put them into bottles accurately, this machine is suitable for packaging liquid detergent in daily chemical industries.

Capping head optional: 1/2 head, single head speed: 20-25BPM. Double head speed: 40-45BPM

Model: VK-TSC

View VideoHigh production capacity, suitable for feeding bottle caps and tighten bottles, which has long tube inside bottles.

Extremely low error rate, automatically placing bottle caps, gripping and rotating, stable and not easy to loosen.

Parameter

| Machine Model | VK-TSC |

| Voltage | 110/220V |

| Power | 900W |

| Capacity | 20-25 Bottle/Min(based on bottle and cap size) |

| Material | 304 SUS |

| Air Pressure | 0.6-0.8Mpa |

| Suitable Bottles | Customize according to sample |

| Cap Feeding Way | Pneumatic fetch |

| Capping Way | Servo drive screw capping |

| Machine Size | About 2900*950*2000mm |

| Packaging Size | About 3020*905*2140mm(machine), 1870*1220*840mm (Vibratory bowl sorter) |

| Packaging Weight | About 600kg(machine), 316kg(Vibratory bowl sorter) |

Working Video

High-Speed Capping Capability: This machine is designed to cap 20-25 bottles per minute, making it an ideal solution for high-volume production lines in food, beverage, and chemical industries.

Automatic and Efficient: With a PLC+ touch screen control system, this machine automates the capping process, reducing labor costs and increasing productivity.

Suitable for Various Bottle Types: The machine is specifically designed for capping plastic spray trigger bottles, making it a versatile solution for various industries, including food & beverage, retail, and factory use.

Long-Lasting and Durable: The machine's core components, including the motor, gear, and PLC, come with a 1-year warranty, ensuring a long and trouble-free operation.

Easy to Program and Maintain: The machine's program control feature allows for easy sharing with filling machines, and its vibration shaking plate capping distributor ensures smooth and efficient capping operations, reducing downtime and maintenance costs for users.

Can work with automatic filling and labeling machine to realize automated production

Designed for capping trigger pump spray caps with long and; soft tubes, higher working accuracy.

1. PLC + touch screen electrical control system.

2. Positioning device, easy to operate and adjust.

3. Suitable for variety of cap types and specifications.

4. Adjustable capping speed, and the tightness can be adjusted according to different caps.

5. The main machine is installed with movable casters to facilitate equipment handling.

| Descriptions | BRAND |

| Capping Motor | Inovance |

| Pneumatic Components | Taiwan AIRTAC |

| PLC | Siemens |

| HMI | Siemens |

| Photoelectric Sensor | LEUZE |

| Relay and Air Switch | Schneider |

| Motor Inverter | Schneider |

| Conveyor Belt Material | 82.6mm wide POM Chain Belt |

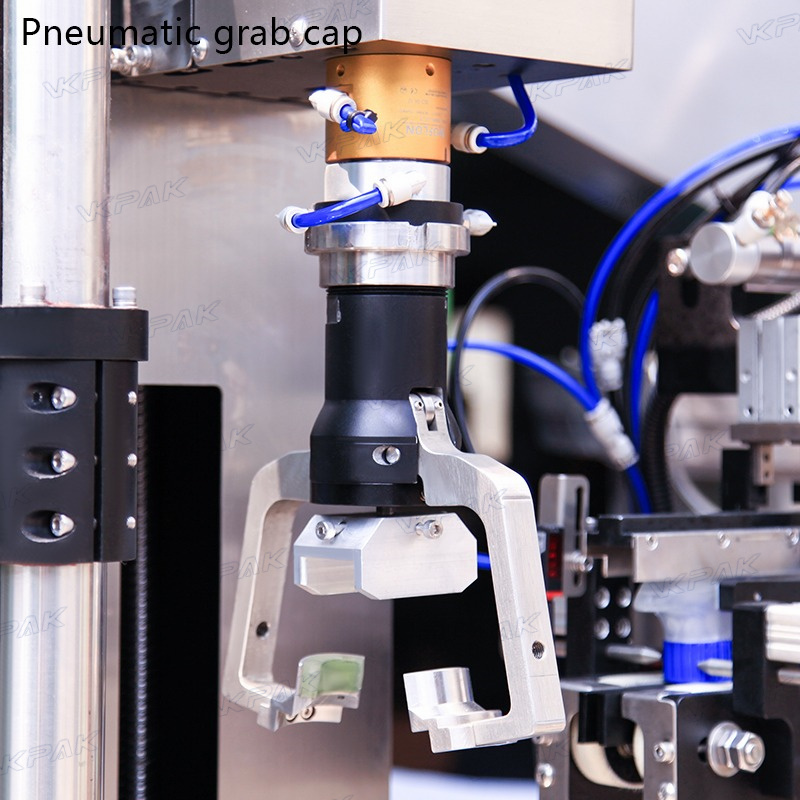

VK-TSC Capping Gripper

Equipped with high quality pneumatic grippers which can stabilize the caps while maintaining high-efficiency operation. The operational parameters will be adjusted according to the characteristics of the bottle caps and the requirements of customer.

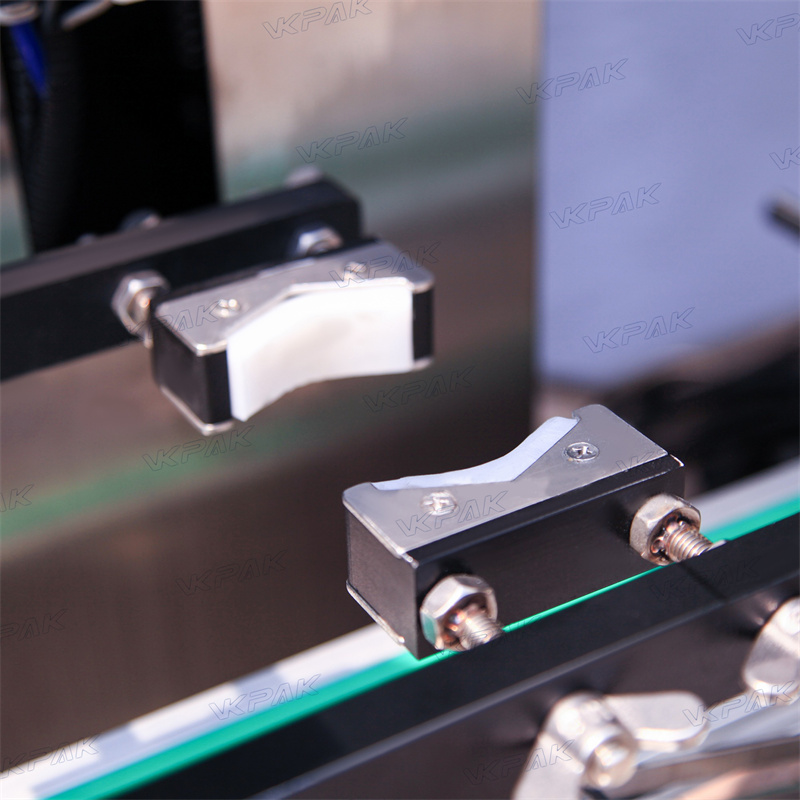

VK-TSC Bottle Fixing Clamp

The bottle clamp operates pneumatically, and when the electric eye detects the bottle, it automatically clamps the bottle body to prevent the bottle from falling down during the capping process, and the soft rubber part protect the bottle from injury.

VK-TSC Capping Station

The station includes bottle cap feeding and capping, cap tube fixing and bottle fixing. When the sensor detects the bottle, both the cap gripper and the bottle clamp work simultaneously, and then the tube gripper clamps and straightens the bottle tube from top to bottom to facilitate capping.

VK-TSC Vibration Bowl Cap Feeder

The vibration bowl feeder can sort bottle caps automatically and push them into the bottle feeding guide rail, which not only speeds up the production speed and efficiency, but also saves labor costs. Customized according to the customer’s sample, smooth and not stuck cap.

VK-TSC Adjustable Hand Wheel

Equipped with multiple adjustable handwheels to adjust the machine’s parameters for the production of different bottles. It makes the process of replacing bottles of different shapes easier and more convenient.

Equipped with cap elevator, this is customized according to cap size, this can ensure the working accuracy. Cap elevator can supply trigger pump caps in time and save working labor.

Vibratory bowl sorter can make caps be in order before capping work and transport them to cap feeding structure. This offers a cost-effective solution for sorting and orienting parts compared to manual sorting.

The cap feeding structure can straighten the long and soft tube and then put caps into bottles automatically, the capping structrue is controlled by servo motor, which has high capping accuracy.

Equipped with electric eye for detecting passing by bottles and send signal to system, this can control the automated capping work in time and improves working efficiency.

Chain conveyor has larger weight capacity, it can transport packaging products more stably and smoothly. The width and length can be customized as needed.