Introduction

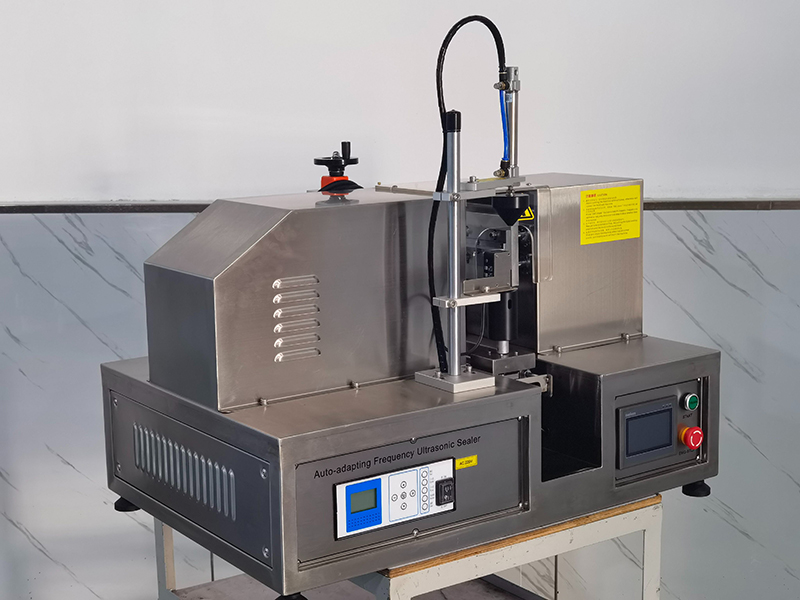

The ultrasonic plastic tube sealer is your quick, convenient solution for packaging small and medium sized plastic tubes. Excellent for use in medical, cosmetic, scientific, and food related environments.

Sealing method: Ultrasonic sealing

Applicable tube materials: plastic tubes, laminated tubes

Speed: 8-15 pcs/min

Experience the future of packaging with our cutting-edge ultrasonic tube sealer. This advanced technology redefines sealing for plastic tubes containing thin to medium viscosity liquids. Achieve unparalleled precision and efficiency as ultrasonic waves create airtight seals, ensuring product freshness and security. Say goodbye to traditional methods and embrace the power of innovation for your packaging needs.

View VideoAn external air source will be needed with this machine.

Great for research and lab use, small batches, and startup operations.

Easy to use, and strong build to deliver continuous quality.

Main Features

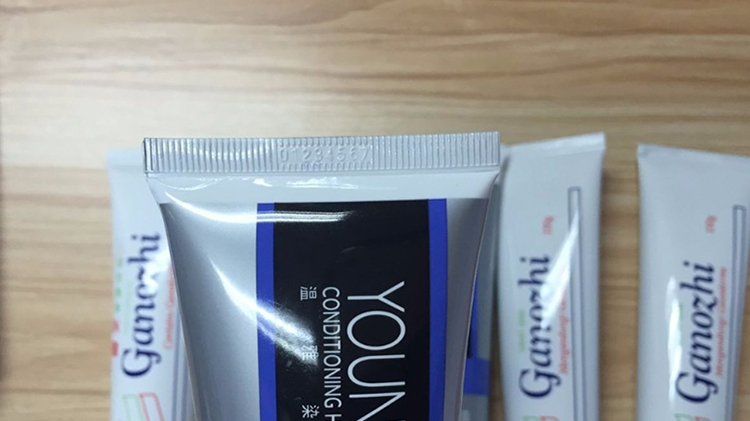

1. Adopts ultrasonic sealing technology, no need warm up time, more stable and neat sealing, no distortion and low reject rate less than 1%.

2. Manually feed the tube, press start button, machine could automatically identify the registration mark, sealing (with coding), end trimming.

3. Independent R &D for digital ultrasonic automatic tracking electrical control box, no need manual adjust the frequency, with power auto compensation function, avoiding the reduction of power after long time use. Could freely adjust the power based on tube material and size, stable and minimum the fault rate, extend the life span than the normal electrical box.

4. PLC with touch screen control system, providing friendly operation experience.

5. Made of 304 stainless Steel, acid and alkali resistance, corrosion resistance.

6. Panasonic high sensitive sensor with stepping motor, could track the registration mark precisely.

7. Table top design, practical and compact.

Working Video

Parameter

| Model | VK-UTS-007 |

| Frequency | 20kHz |

| Power | 2600W |

| Power supply | AC220V/110V |

| Capacity | 8-15pcs/min |

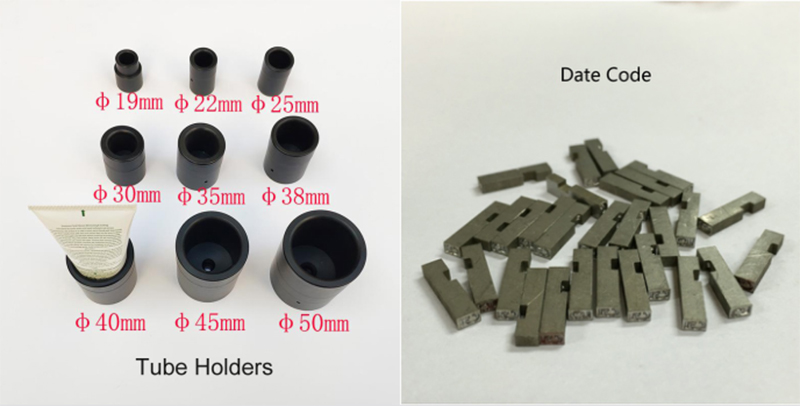

| Tube diameter | 13-50mm |

| Tube height | 50-250mm |

| Working pressure | 0.5 MPa |

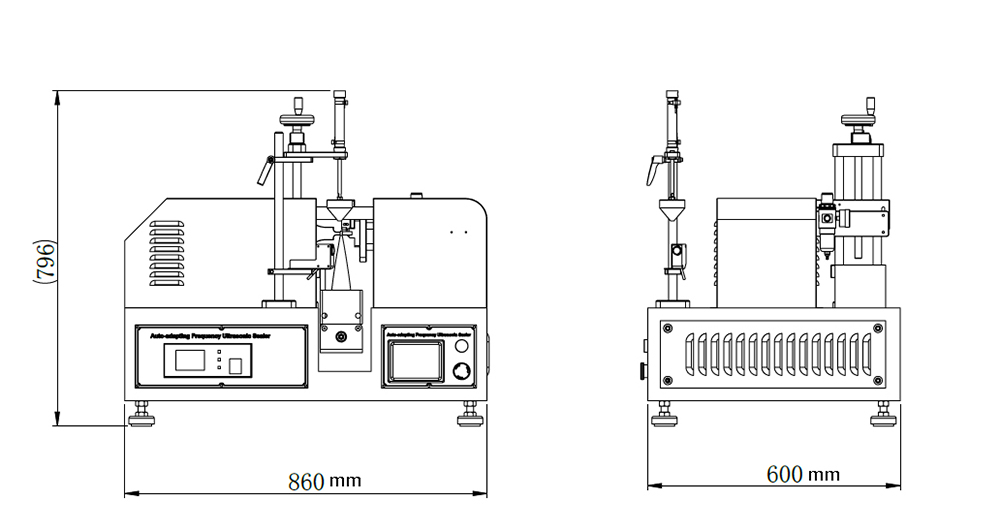

| Size | L850mm*W600mm*H730mm |

| N.W/G.W | 75kgs |

Drawing

Images

1. It's applicable to toothpaste, cosmetic, pharmaceutical, food, industry product and other soft tube sealing.

2. Extensional organization of the machine is made of aluminium alloy and stainless steel.

3. The working platform is easily to operate that is independent man-machine operating interface and can be two dimension direction adjustment.

4. The ultrasound power supply adopts Taiwan movement circuitry, ultrasound parts use famous brands.

5. It's with the function of overload protection, phase difference protection, and power-fail protection

6. The ultrasound output power is big enough to ensure the sealing quality of different kinds material and specifications soft tubes.

7. It's with the function of automatically cutting.

Application

Widely used for food, pharmaceutical, cosmetics, chemical and other plastic, PE, aluminum laminated tube sealing. Such as: Ointment, adhesive, AB glue, skin cream, hair dye, shoe polish, and other liquid or paste-like materials.

Options

| Ultrasonic system | Automatic frequency tracing |

| Benchmarking electric eye | Panasonic, Japan |

| PLC screen | Coolmay,CN |

| Electric relay | Omron, Japan |

| Inductive switch | SICK, Germany |

| Air cylinder | AirTAC,China Taiwan |

| Solenoid valve | AirTAC,China Taiwan |

| Stepper motor | JMK motion,CN |

| Air source processor | AirTAC,China Taiwan |

Auto Tube Orientation

Using high sensitivity Japan-Imported Panasonic infrared positioning system, plastic tube will be turning to right side according to the mark on the tube

Auto Ultrasonic Sealing & Coding Function

Using Japan ultrasonic technology, sealing the plastic tube and coding on it, standard coding is 20231025.

Auto Cutting Function

It’s with the function of automatically cutting after sealing and coding, in which guarantee the tube tail more beauty.

Imported AirTAC Solenoid Valve

Adopting famous brand AirTac air system, greatly make the machine pressure working precisely.