Introduction

VK-TFS-009U is a machine model designed for cosmetic, food, pharmaceutical factories. It can process a whole line including tube feeding, mark orientation, filling, ultrasonic sealing, trimming and auto eject out.

Sealing method: Ultrasonic sealing

Applicable tube materials: plastic tubes, laminated tubes

Speed: 20-30 Tubes/min

The machine is suitable to fill and seal cosmetic cream, skin care, daily chemical, pharmaceutical ointment, food paste, gear oil and various viscosity products in plastic tube container.

View VideoVK-TFS-009U is a fully automatic machine. You don't need to be worry about the complex adjustment. Put your tubes into tube hopper and start the machine, then the machine will do all the jobs. This machine is especially suitable for mass production. We have provided this machine for cosmetic, pharmaceutical, chemical production plant and got a lot of good reviews.

Working Video

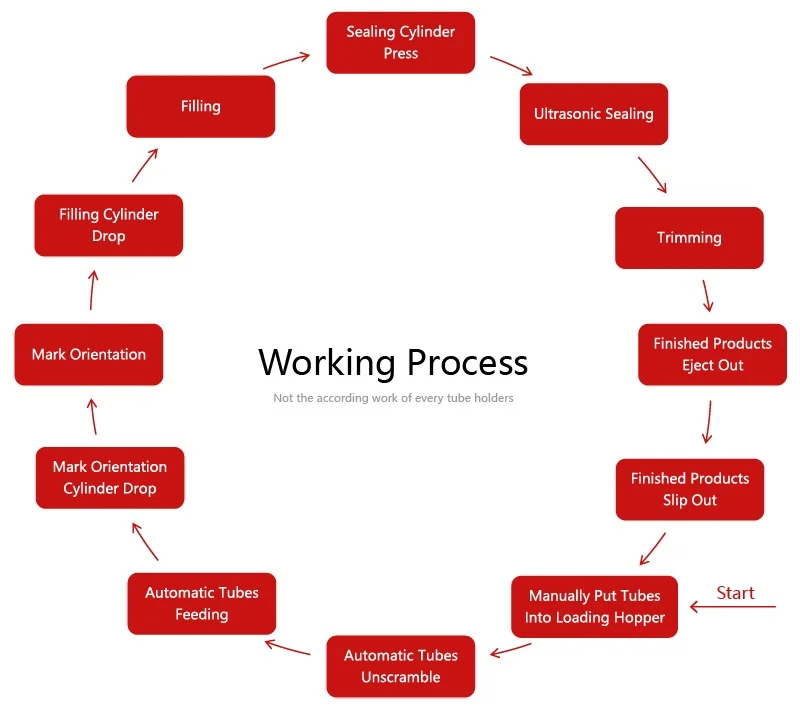

Working Process

Automatic Tube Feeding→ Auto Tube Orientation → Auto Filling → Auto Sealing → Auto Cutting → Auto Producing Date Coding → Auto Trimming → Auto Tubes Output

Parameter

| Model | VK-TFS-009U |

| Sealing Dia | 5-50mm |

| Output power | 2000W |

| Voltage | AC220V/single phase 50/60HZ |

| Machine weight | 555kgs |

| After packaging | 590kgs |

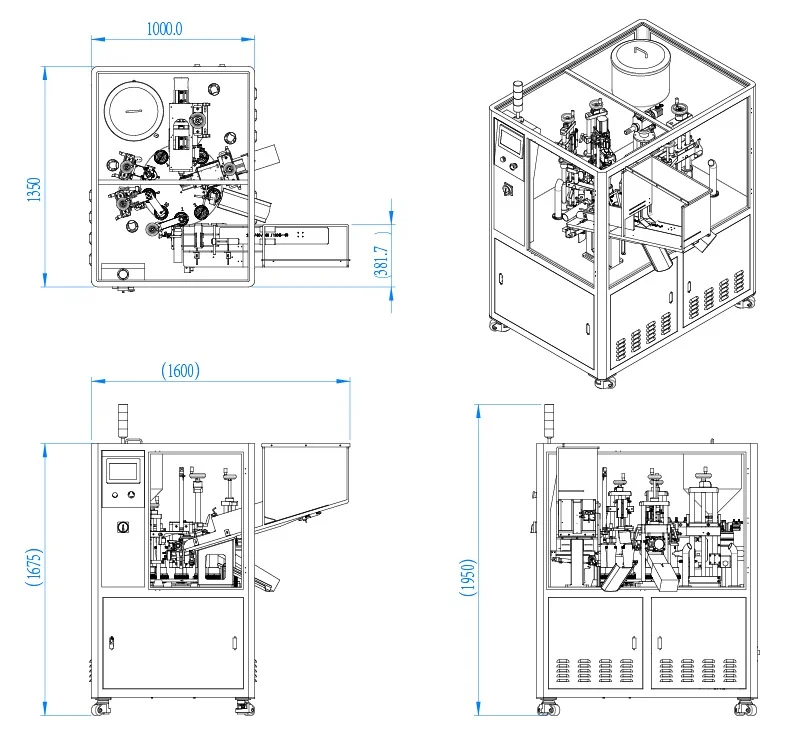

| Machine size | 1630*1300*1580mm |

| Filling Range | A:6-60ml, B:10-120ml, C:25-250ml, D:50-500ml (Customer made available) |

| Control Style | PLC control |

| Time adjust | electronic adjust |

| Packaging | Plywooden case packaging |

Main Features

1. This machine could automatically finish tube feeding, registration mark identifying, filling, sealing with coding, end trimming, tube out feeding, fully automatic, save labor cost and lower production cost.

2. This machine is equipped with safety protection device and overload protection.

3. Cam indexing system could position precisely for ten working stations.

4. Adopts ultrasonic sealing technology, no need warm up time, more stable and neat sealing, no distortion and low reject rate less than 1%.

5. Independent R & D for digital ultrasonic automatic tracking electrical control box, no need manual adjust the frequency, with power auto compensation function, avoiding the reduction of power after long time use. Could freely adjust the power based on tube material and size, stable and minimum the fault rate, extend the life span than the normal electrical box.

6. PLC with touch screen control system with alarm system, could directly view the alarm information on the touch screen, could locate the problem and solve immediately.

7. Made of 304 stainless steel, acid and alkali resistance, corrosion resistance.

8. No tube, no fill, no tube, no seal function, reducing the machine and mould loss.

9. Adopts anti-dripping filling nozzle.

Drawing

Machine Options

- Auto refill pump

- Double jacket heating hopper with stirrer

- Filling nozzle with air blow

- 316 stainless steel contact parts

- Saftey door function

- Pressurer hopper

- Date coding

Images

Application

Automatic ultrasonic tube filling and sealing machine is an ideal machine for use in the pharmaceutical, chemical, cosmetic, foodstuff and other light industries. This tube filler can be used to fill all kinds of semi-viscous and viscous products into soft plastic or flexible compound tubes.

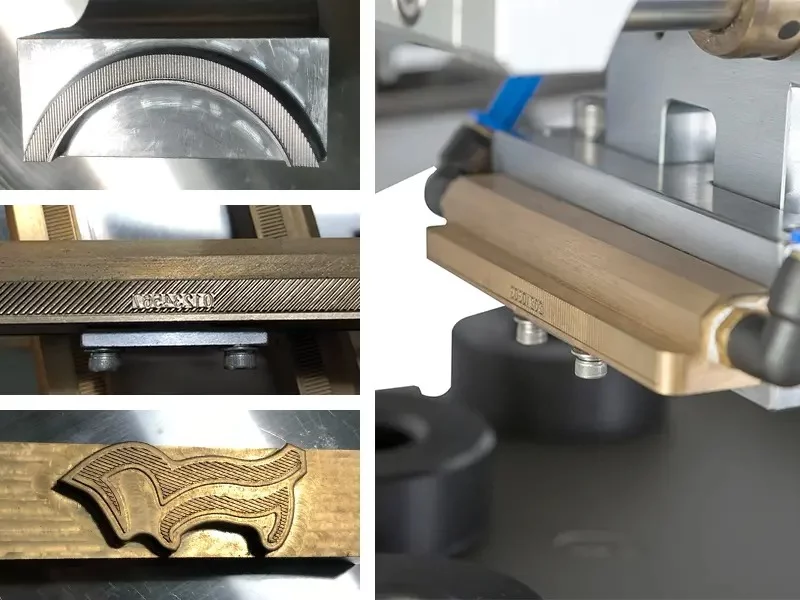

Tube Tail Trimming Shape

| Ultrasonic system | Automatic frequency tracing |

| Benchmarking electric eye | Panasonic, Japan |

| PLC | Mitsubishi, Japan |

| Electric relay | Omron, Japan |

| Touch Panel | WEINVIEW, China Taiwan |

| Inductive switch | SICK, Germany |

| Air cylinder | AirTAC, China Taiwan |

| Solenoid valve | AirTAC, China Taiwan |

| Motor | Zhongdamotor CN |

| Partitioner | JOUDER, China Taiwan |

| Frequency converter | DELTA, China Taiwan |

| Stepper motor | Leadshine, CN |

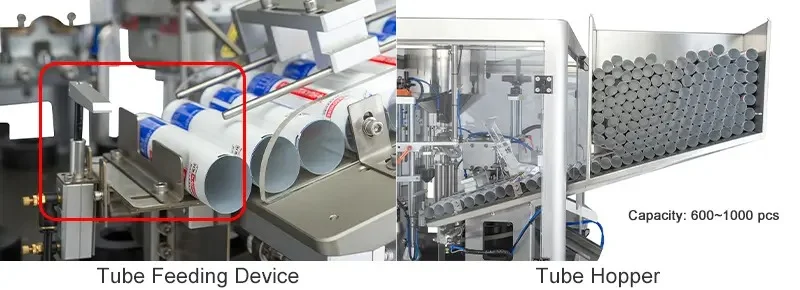

Tube Feeding

The machine can automatically feed tubes into rotary working station. You just need to place the tubes into tube hopper in certain direction. Then the machine will automatically do it. You can easily change the part to fit varius dimensions tubes.

Mark Orientation

Rotate the tubes to the correct direction. The machine equips a high precision electric eye. Suitable for a range of contrast of mark color. And it’s easy to set the color mark sensor. The default brand is Panasonic from Japan.

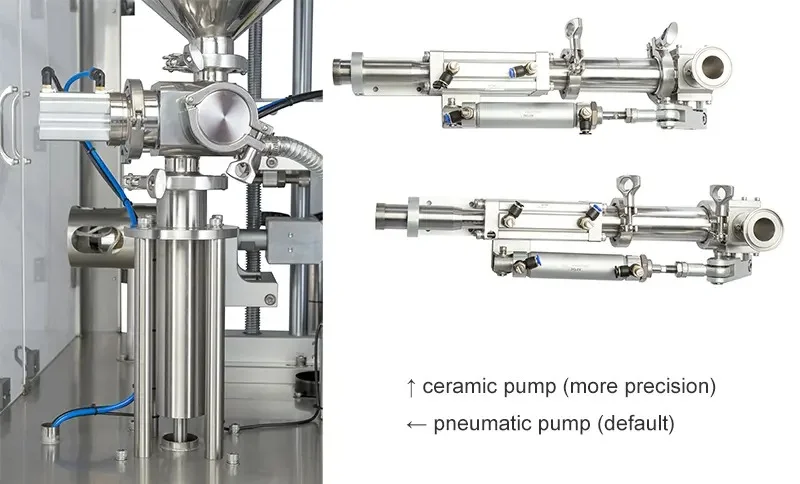

Tube Filling

The default filling method is pneumatic pump, which provide a good applicability of filling different viscous liquid, like water, oil, gel, cream or paste. We have tested the machine to fill honey, face cleanser, sunscreen, ointment.

Ultrasonic Sealing

As we have many years experience of ultrasonic sealing, our machine is stable for sealing power and has good quality of sealing effect. We accept customization of sealing pattern like straight, mesh or irregular.

Tube Trimming

The default trimming method is flat cut, which gives a flat cut tail affect. The trimming height is easy to adjust to meet different needs. And the replacement is convenient. You can change the cutter to varius shape. Like rounded corner, wave shape, euro hole and so on.

Tube Eject Out

The machine will auto detect the finish products and eject them out. So it prevent the finish products from being left on the turntable and causing problems. Meanwhile, it is convinient for cooperating with other machines like labeling machine.