Introduction

VK-TFS-009A automatic aluminum tube filling and sealing machine is suitable for metal soft tubes. It can do automatic color mark position, filling, folding, batch coding and finished products exit in one machine. Widely used in pharmaceutical industry, commodity industry, food industry and chemical industry. Such as: Ointment, toothpaste, AB glue, shoe polish etc.

Sealing method: Folding sealing

Applicable tube materials: Aluminum tubes, metal tubes

Speed: 40-60 Tubes/min

It is the automatic equipment. This machine will drive the 16 station. We manual put the aluminum tube into the tube feeding box. The machine then will auto go into the tube base. Next station is with auto eye-marking system, auto filling and auto crimping. Filling sensor auto checks if there is tubes. It will filling when it detects tubes. No filling when no tube which will avoid wrong filling. The filling is driven by cylinder and the filling capacity and accuracy is controlled by cylinder route.

View VideoThe machine has a modern shape, a strong practicability and good value for process, it is widely used in toothpaste, ointment, paste food, cosmetics, hair-dyeing, adhesive, art palette and so on.

Working Video

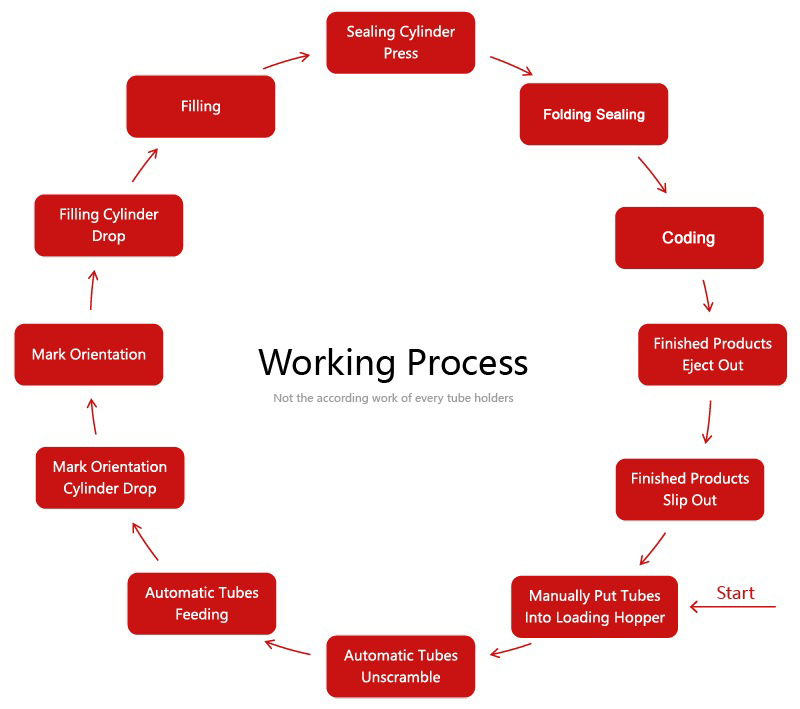

Working Process

Manually put the metal tube into the position, using mechanical transmission transposition, photoelectric detection device to confirm the tube in the tube position, material through the metering pump quantitative injection tube, then the sealing mechanism of tube sealing, printing, sealing after finished product launch automatically.

Parameter

| Model | VK-TFS-009A |

| Power supply | 220V/ 380V double voltage |

| Power | 5KW |

| Filling Range | 0-500g |

| Suitable tube | Metal Tube, Aluminum Tube |

| Working Station | 16 (Different stations for different folding methods) |

| Working capacity | 40-60pcs/minute (Tube size and folding method all have an effect.) |

| N.W | 380kg |

| Dimension | 1600*900*1800mm |

| HS code | 8422303090 |

Main Features

1. Aluminum tube filling and sealing machine is made of high-quality stainless steel SS 304;

2. All elements having contact with the product are made of high-quality stainless steel SS 304 or SS 316 (optional);

3. Touch screen and PLC control of sealing parameters and process with saving option;

4. Filling accuracy error: <±1% of volume;

5. Single-sided coding with set of fonts included;

6. Double fold closing (Multiple tail folding options);

7. Output up to 40~60 tubes/minute;

8. Works with all-aluminum tubes.

Advantages

- Small and saving space

- Efficient and precise

- Easy to operate and flexible

- Stainless steel body, neat and beautiful

Images

The aluminum tube filling and crimping machine is used for filling of aluminum tubes with gels, creams or other fluids, crimping (closing) them and stamping date and / or batch No.

The aluminium tube filling device loads empty cosmetic tubes automatically. Subsequently, they are positioned, filled and closed. The date or batch number is being stamped. The tube filling and sealing machine removes end-products automatically.

Application

An aluminum tube filling and sealing machine is used for packing cosmetics, pharmaceuticals, chemicals, and food products into metal tubes. The aluminum tube filling machine is designed to handle large and medium-size batches / production lots / jobs.

Turntable Working Stations

16 working stations for filling, folding. more efficient;(Different stations for different folding methods)

Equip Mark Sensor

Guarantee every tube seal at the right position;

Anti-dropping Filling Nozzles

Making filling more precious, less filling error;

Operation Board

Usng button style, simple to adjust and operate.