Introduction

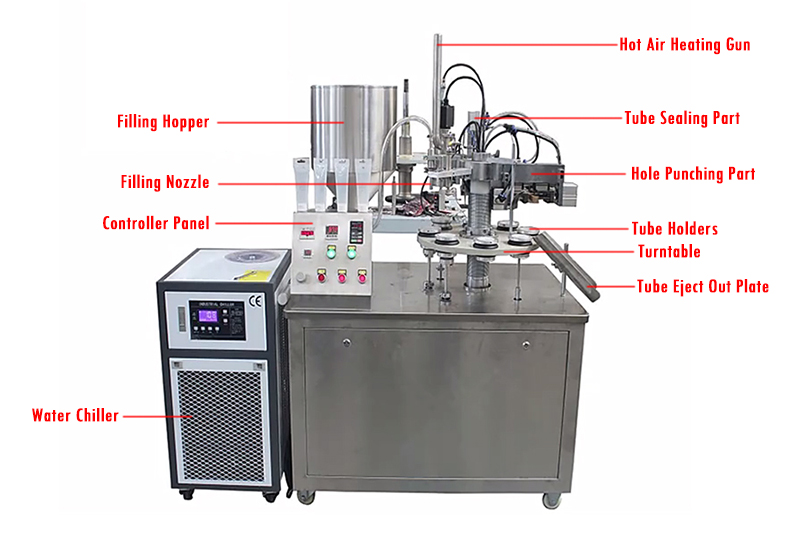

VK-TFS-006H semi auto plastic tube filling and sealing machine adopts indexing device, completing a series of functions, including automatic filling, inside and outside heating, end-sealing, batch number printing, and finished product exiting. The machine is featured by accurate filling, stable and adjustable heating time, good sealing effect. The machine works stably and reliably, without noise and other pollution.

Sealing method: Hot Air Sealing

Applicable tube materials: plastic tubes, laminated tubes

Speed: 25-40 pcs/min

The tube filling and sealing machine can suitable for materials such as paste, adhesives, AB glue, epoxy glue, skin cream, hair dye, shoe polish, toothpaste and so on.

The tube filling machine can be customized by end user asked, can upgrade with auto tube loader.

View VideoThe machine is driven by a motor as the main power, goes through a worm gear reducer and performs variable frequency speed regulation. Through a set of sheaves, the gears run intermittently, so that the fixtures mounted on the turntable are equiangularly moved. (Isometric movement: the stroke of each fixture is the same when it runs to the next position) After the tube is manually loaded, filling process resumes. The whole filling system is driven by cylinders and is equipped with a metering adjustment screw, which can be adjusted within a certain range, and the accuracy can reach ±1%. In order to prevent the material from dripping, the filling nozzle of the machine is in the form of insertion, and the advance and retreat movement is driven by the lifting cylinder.

Working Video

Parameter

| Model | VK-TFS-006H |

| Weight | 250Kg |

| Power | 220V/50Hz |

| Filling Quantity | 5ml-75ml/75-250ml |

| Air Consumption | <30 m³/min |

| Compressed Air | 0.6-0.8Mpa |

| Dimension | 1300*700*1400mm |

| Motor | 4.5Kw |

| Capacity | 20-30 tubes/min |

| Tube size | 35mm |

| Quantity Error | <1% |

Main Features

1. Automatic rotary table with 8-10 tube holders, servo motor control;

2. Adopt digital ultrasonic circuit, stable output and performance;

3. Machine body of stainless steel, meet with GMP requirement;

4. PLC/HMI control, simple operation and parameters setting;

5. Machine with mark searching function, more precise sealing;

6. Main parts adopt imported components, Japan and Taiwan;

7. Suitable for plastic tubes, composite tubes, PE tubes.

Images

Main Workflow

- Manual loading tube

- Automatic benchmarking

- Aumatic filling and no tube no filling and could be bottom filling system according to customer materail viscosity

- Automatic heating (inner heating and outer heating)

- Automatic sealing and printing the date code

- Automatic cut the over part after sealing then output finish product

Application

This semi-automatic tube filling sealing machine can fill and seal plastic tubes and lami tubes. It is widely used in the glue, cosmetics, creams, lotion, medicine, lubricants, adhesive and shoe polish, and food industries.

| SETUP Component | brand |

| Main Motor | China / Shanghai |

| Transducer | China/ Woshen |

| PLC / Colour sensor | Panasonic |

| Temperature control | China/Hu Nan |

| Divider | China/Shandong Copy from Taiwan |

| Air cylinder | S SHINIGE |

| Solenoid valve | China |

| Water oil separator | China |

| Heating tube | China |

| Approach switch | China, Qianwei |

| Media relay | Omron |

| Power switch | Omron |

| Heating gun | Swiss Leister |

| Shell | SUS304 |

| Step motor / Drive | Japan East |

| Filling nozzle & pump Heat cooper Cutter | |

| Button | Schneider |

Operate Control System

Operator through panel control the machine each part running

- Auto/Manual Running

- Filling/Sealing Independent Switch

- Speed Adjustment

- Sealing Temperature Adjustment

- With Counting Function

Tube Benchmark Photoelectric

According tube tail mark do auto calibrate and turning to correct position

- With Tube Detect System

- No Tube No Filling

Tube Filling System

Auto filling material into each tubes

- Suitable for various material

- Working for different filling volume

Tube Sealing System

Auto sealing each tubes

- Suitable for various tube material seal

- Can upgrade by Swiss hot gun type

Tube Coding System

Auto coding date or batch number on each tubes

- Customized numbers & letters& symbol

- Customized for coding length & width

- Customized for one or two sides