Introduction

Ultrasonic tube filling and sealing machine is a high-quality, high-performance liquid, paste tube filling and sealing packaging machine, which adopts manual tube loading, automatic color-code detection, automatic filling, automatic sealing, automatic cutting of the tail material, PLC control, touch human-machine interface.

The operation of this equipment is simple, stable and reliable, improve enterprise production efficiency, reduce labor intensity, is the first choice of equipment for filling and sealing.

Used For: plastics tubes, laminated tubes

View VideoParameter

| Model | VK-TFS-002U Semi Automatic Ultrasonic Tube Filler And Sealer Machine |

| Frequency | 20KHZ |

| Power | 2kW |

| Power Supply | AC220V/110V 1PH 50/60HZ |

| Filling Range | A: 6-60ml B: 10-120ml C:25-250ml D:50-500ml (could choose based on customer’s volume) |

| Filling Accuracy | ±1% |

| Capacity | 10-15pcs/min |

| Sealing Dia. | 13-50mm |

| Tube Height | 50-200mm |

| Air Pressure | 0.5-0.6MPa |

| Dimension | L860*W670*1570mm |

| Net Weight | 180kgs |

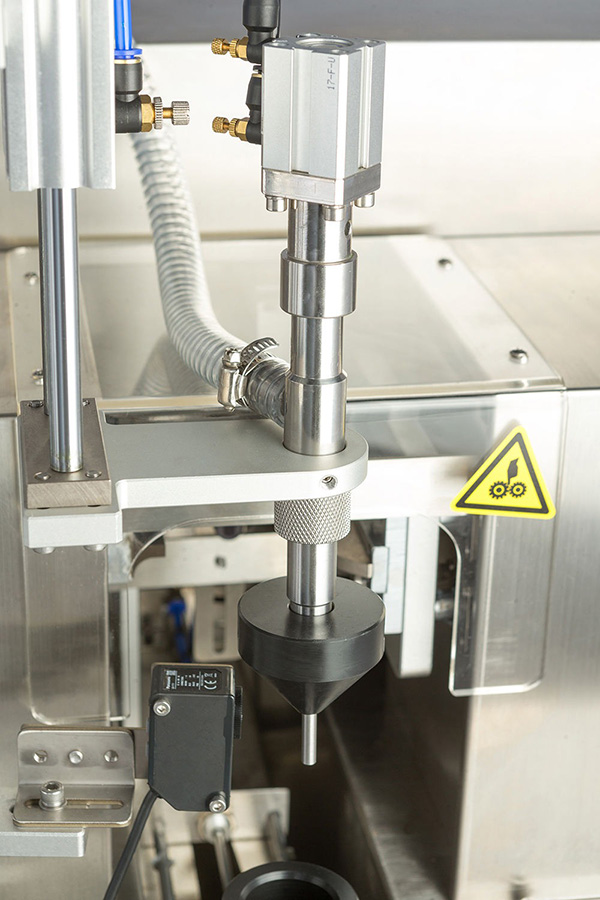

Details

Features

1. Adopts ultrasonic sealing technology, no need warm up time, more stable and neat sealing, no distortion and low reject rate less than 1%.

2. Manually feed the tube, press start button, machine could automatically identify the registration mark, filling, sealing with coding, end trimming.

3. Independent R & D for digital ultrasonic automatic tracking electrical control box, no need manual adjust the frequency, with power auto compensation function, avoiding the reduction of power after long time use. Could freely adjust the power based on tube material and size, stable and minimum the fault rate, extend the life span than the normal electrical box.

4. PLC with touch screen control system, providing friendly operation experience.

5. "Panasonic" high sensitive sensor with stepping motor, could track the registration mark precisely.

6. Equipped with filler for both liquid and cream, with filling tolerance within ±1%.

7. Made of 304 stainless Steel, acid and alkali resistance, corrosion resistance.

Work Process

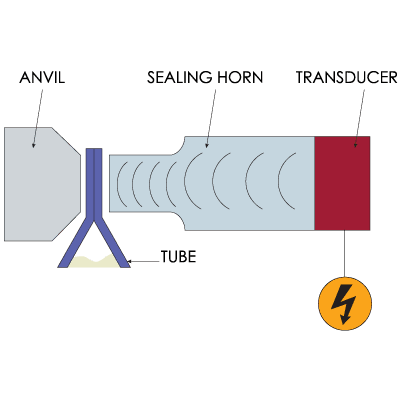

Ultrasonic Tube Sealing

Ultrasonic Tube Sealing

Ultrasonic tube sealing is a method where plastic and laminate tubes are sealed by the high frequency vibration of an ultrasonic sealing horn. This vibration heats the plastic of the tube in the seal area causing the plastic to melt. The end of the tube is held closed under pressure between the sealing horn and matching anvil to cool and complete the tube seal. Ultrasonic tube sealing requires less change parts and can seal through product contamination in the seal area but is slower than Hot Air or HF Sealing. Ultrasonic Sealing does not give the same high quality visual appearance that is produced with hot air sealing.

Automatic Tube Filling And Sealing Machine

| Ultrasonic system | Automatic frequency tracing |

| Benchmarking electric eye | Panasonic, Japan |

| PLC screen | Coolmay, CN |

| electric relay | Omron, Japan |

| Inductive switch | SICK, Germany |

| Air cylinder | AirTAC, China Taiwan |

| Solenoid valve | AirTAC, China Taiwan |

| Stepper motor | JMK motion, CN |

| Transducer | CN |

| Air source processor | AirTAC, China Taiwan |

| Foot switch | DELIXI, CN |

Compared with heat sealing, the ultrasonic tube sealing has the following advantages:

* Fast Sealing, save time

* Sealing is nice looking, different shape sealing

* Lower power consumption, energy saving

Auto Tube Orientation

Using high sensitivity Japan-Imported Panasonic infrared positioning system, plastic tube will be turning to right side according to the mark on the tube

Auto Ultrasonic Sealing & Coding Function

Using Japan ultrasonic technology, sealing the plastic tube and coding on it, standard coding is 20201020.

Auto Cutting Function

It’s with the function of automatically cutting after sealing and coding, in which guarantee the tube tail more beauty.

Imported AirTAC Solenoid Valve

Adopting famous brand AirTac air system, greatly make the machine pressure working precisely.