A dosing machine is a type of equipment used to accurately measure and dispense a specific amount of material—whether liquid, powder, or granular—into a process or container (commonly bottles, tubes, jars, bags, etc.). They are commonly used in industries such as pharmaceuticals, food and beverage, chemicals, and manufacturing, where precise measurements are crucial for quality and consistency.

In the world of industrial packaging and processing, precision and efficiency are paramount. One crucial piece of equipment that plays a vital role in ensuring accurate portioning of liquids, powders, and granules is the dosing machine. The term "dosing machine" is commonly used in Europe. Whether in the food and beverage, pharmaceutical, chemical, or cosmetic industries, dosing machines help manufacturers maintain consistency, reduce waste, and improve production efficiency.

Types Of Dosing Machines

Dosing machines come in different types based on the material they handle and the dosing mechanism they use.

Based on the materials to be measured, they can be divided into the following categories:

1. Liquid Dosing Machines

Liquid dosing machines are used to dispense precise amounts of liquid substances. These machines are commonly used in industries such as pharmaceuticals, food and beverage, and chemicals. Common liquid dosing technologies include:

1.1 Piston Dosing Machines

Use a piston mechanism to dispense a fixed volume of liquid. Ideal for high-viscosity liquids like sauces, creams, and gels.

1.2 Peristaltic Pump Dosing Machines

Utilize flexible tubing and rollers to move liquid, ensuring hygiene and minimal contamination. Often used in pharmaceuticals and lab applications.

1.3 Gravity-Based Dosing Machines

Rely on gravity to dispense liquid, suitable for free-flowing and low-viscosity liquids.

1.4 Gear Pump Dosing Machines

Use rotating gears to dispense precise amounts of liquid, commonly found in chemical and industrial applications.

2. Powder Dosing Machines

Powder dosing machines are used for dispensing powdered substances in industries like pharmaceuticals, food processing, and cosmetics. Common types include:

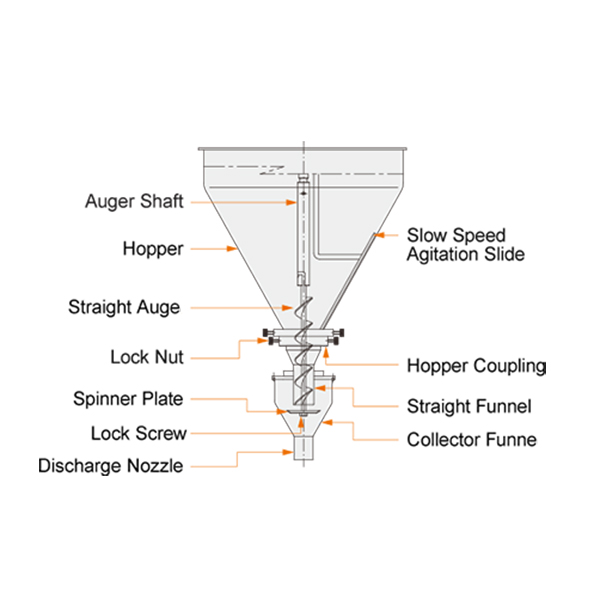

2.1 Auger Dosing Machines

Use a rotating screw (auger) to dispense a set amount of powder. Suitable for fine powders like flour, protein powder, and pharmaceutical powders. Works well with free-flowing and non-free-flowing powders.

2.2 Weighing Dosing Machines

Measure powder by weight for highly accurate dosing. Used when precision is critical, such as in pharmaceuticals and high-value powders.

2.3 Volumetric Cup Dosing Machines

Dispense powder based on volume rather than weight. Faster but slightly less precise than gravimetric systems. Often used for bulk packaging applications.

2.4 Vibratory Dosing Machines

Utilize vibration to move powder from a hopper to the dosing container. Ideal for fragile or irregularly shaped powders and granules. Common in food and chemical industries.

2.5 Vacuum Powder Dosing Machines

Use suction to transport and dose powder. Suitable for ultra-fine powders that need gentle handling. Common in chemical and pharmaceutical industries.

3. Granule Dosing Machines

Granule dosing machines handle granular materials such as seeds, coffee, and detergents. These machines use:

Weighing Systems: Gravimetric methods ensure precise weight-based dosing.

Cup Fillers: Suitable for free-flowing granules.

Multi-Head Weighers: Used in high-speed production lines for bulk dosing.

4. Gaseous Dosing Machines

In industries such as pharmaceuticals and food packaging, gaseous dosing machines dispense precise amounts of gas, such as nitrogen, to preserve product freshness and extend shelf life.

Based on the measurement method, it can be divided into the following categories:

1. Volumetric Dosing Machine:

Measures and dispenses materials based on volume. Uses a fixed volume for each dispensing cycle. Common in liquid or granular products where precise volume is needed. Example: Piston-type fillers, gear pumps.

2. Gravitational Dosing Machine:

Relies on the weight of the material for measurement. The material is dispensed until the desired weight is reached. Widely used for powders, granules, or other materials that can be weighed accurately.

Main Components and Functionality

At its core, a dosing machine consists of several integral components:

Feeder System: This part regulates the flow of material into the dosing chamber. It can handle different types of materials, from free-flowing powders to viscous liquids.

Dosing Chamber: The heart of the machine where the precise quantity of material is measured. The chamber’s design may vary depending on the type of material and the required dosage.

Piston or Pump Mechanism: In many dosing machines, a piston or pump is used to push the material out of the chamber into the packaging container. This mechanism is designed for both speed and accuracy.

Control Unit: Modern dosing machines incorporate sophisticated electronic control systems that allow for exact dosage settings. These controls can be adjusted to accommodate varying product types, ensuring consistency across large production runs.

Sensors and Feedback Systems: These components monitor the process in real time, ensuring that any deviations from the set parameters are corrected immediately. This is critical in preventing product waste and ensuring adherence to quality standards.

How to Choose a Dosing Machine?

Selecting the right dosing machine involves understanding the specific needs of your production process and the characteristics of the materials you are working with. Here are some important factors to consider:

♦ Material Properties

Different materials behave in various ways. For instance, powders may have a tendency to clump, while liquids might require specialized pump mechanisms to handle viscosity differences. It is essential to choose a dosing machine that is compatible with the physical properties of your material to ensure smooth operation.

♦ Production Volume

The required production volume will directly impact the type and size of the dosing machine you need. High-volume operations may necessitate a machine with a faster dosing cycle and a robust design that can operate continuously without breakdowns. Conversely, smaller production runs might benefit from a more compact and versatile machine.

♦ Precision Requirements

The level of dosing precision required can vary by industry. For pharmaceutical or chemical applications, even minor deviations can have significant consequences. Manufacturers should assess their precision requirements and select a dosing machine that can meet these stringent standards.

♦ Integration with Existing Systems

Modern production lines are often complex and interconnected. The dosing machine you select should seamlessly integrate with your existing packaging and filling equipment. This integration can involve compatibility with various control systems, ease of maintenance, and the ability to adapt to future technological advancements.

VKPAK offers a comprehensive range of bottle dosing machines, designed to handle liquids, pastes, powders, and granules with precision. Whether you need a semi-automatic or fully automatic solution, we have the right equipment to optimize your production process. Contact us today, and our expert engineers will help you find the perfect dosing machine tailored to your specific needs.