Jar is a container for packing liquids or small particles, and is the choice of many packagers. In this article, we will learn more about the filling solutions for a wide variety of jars.

What is a Jar?

Automatic Glass Jar Sauce Filling Machine

This filling machines are customized base on different products, filling volume and capacity required. Bottle unscrambler machine, filling machine, capping machine, labeling machine, ink coding machine and packaging machines can be addedas an option and combine freely.

Filling volumes can be adjusted easily in the touch screen. We use quick and fast joints for building the machines which is easy for dismentling the machines and maintenance, and convenient for cleaning.

Filling nozzles are customized depends on your capacity required. 2 nozzles, 4 nozzles, 6 nozzles, 8 nozzles, 10 nozzles or more are available.

Honey Jar Filling Machine

This automatic piston pump filling machine is equipped with feeding pump, this is more convenient for feeding filling material. Different filling range can be chosen and multiple filling nozzle can be customized according to operation need.

It is widely used in the filling of various semi-fluids, pastes, viscous bodies, sauces and various granule-containing material, such as pulp-containing beverages, shampoo, laundry detergent, hand washing, honey, jams, ketchup, chili sauce, bean paste, shrimp paste, apple sauce, salad dressing.

Cream Jar Filling And Capping Machine

This is 2 in 1 one machine by using round turn plate. According to different jar size, the star wheel, should be also changed. The machine is with no jar no filling function. The machine is controlled by PLC This machine is suitable for filling medium viscosity cream

This cream jar filling and capping machine is using German advanced technology, engineering and technical personnel by the company independently developed specifically for liquid filling and capping. Filling part of the machine can be used 316L stainless steel piston pump filling, PLC control, high filling accuracy, easy to adjust the scope of the filling, capping method using constant torque capping, automatic slip, capping process does not damage material, to ensure the packing effect. The machine design is reasonable, reliable, easy to operate and maintain, in full compliance with GMP requirements.

Semi Automatic Jar Filling Machine

The whole machine is made of high quality stainless steel, and the shape is novel and beautiful. And the quantitative is correct, the dispensing error is small, and the adjustment is simple. It is the most ideal small-sized equipment for small-dose liquid quantitative dispensing in hospitals, pharmaceutical factories, beverage factories, daily chemical plants, scientific research experiments, etc. Usually, the semi-automatic liquid filling machine divided into single filling Nozzle or double filling nozzle according to the needs of different customers.

Types Of Jar Filling Machines

According to the degree of automation of the filling machine, or according to the output to divide the jar filling machine can be divided into semi-automatic and automatic filling machine. In general terms, automatic equipment will require little to know interaction with an operator once the machine is set up and running. Semi-automatic equipment will require a more hands on approach, with an operator assisting the machine at every cycle.

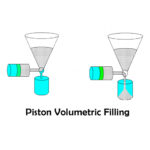

According to the metering principle, Jar filling machines can be divided into overflow filling machines, gravity filling machines, pump filling machines, piston filling machines and net weight filling machines, where overflow filling is typical of liquid level filling, while the other types of filling machines are all quantitative: gravity filling is time-based; pump filling is time or pulse-based; piston filling is volume-based and net weight filling is weight-based.

Choose VKPAK

We support you from the start of your project to the startup of your machine or system. In fact, our technicians have the knowledge and experience to help you determine the best filling equipment for your business needs — from a simple jar filling machine to a fully automatic filling line. And when it’s time for maintenance or an upgrade, we’re here for you, too! Contact VKPAK for all of your jar filling machine questions and needs today.