A Piston Filling Machine is a type of liquid filling equipment that uses a piston-cylinder mechanism to dispense a precise volume of liquid or semi-liquid products into containers. It operates by drawing product into a cylinder during the intake stroke and then pushing it out into the container during the discharge stroke.

You can choose from the following piston filling machines:

VK-PF is a traditional piston filling machine. When the bottle enters the filling station, the bottle stopper mechanism temporarily fixes the bottle, and then the filling nozzle corresponding to the mouth of the bottle is fixed on top of the bottle to start dispensing the material. After dispensing the specified amount of material, the bottle stopper mechanism releases the filled bottles. This cycle completes the batch filling. The number of filling nozzles can be set to 1,2,4,6,8,10,12,14,16, the more nozzles the higher the efficiency.

VK-PF-T is tracking piston filling machine. When bottles enter the filling station, the movable filling nozzles track the bottles one by one to complete the dispensing of the specified amount of material. The filling nozzles and bottles run one-to-one tracking and the bottles do not stop at the filling station. Higher efficiency. This filling machine can be equipped with 2, 4, 6 or 8 filling nozzles.

VK-PF-M is a mobile piston filling machine that combines the VK-PF and VK-PF-T designs to improve filling efficiency by moving multiple filling nozzles in one piece with multiple bottles, which dispense material as they move. The filler can be configured with 6,810,12 filling nozzles.

VK-EPF is an economical piston filling machine with the dust protection frame removed from the VK-PF and can be configured with 1, 2 or 4 filling nozzles. It is suitable for small and medium-sized enterprises with low budget.

VK-SPF series is semi-automatic piston filling machine. The container is placed under the filling nozzle by hand, the foot pedal controls the material to start filling (timed intervals can also be set for automatic filling), and then the filled container is taken away by hand. Sequential cycle to complete the batch dispensing.

Main Features:

High Accuracy: Ideal for filling products with consistent volume.

Versatile: Suitable for a wide range of viscosities, from thin liquids to thick pastes.

Adjustable Fill Volume: The stroke length of the piston can be modified to control the amount of product dispensed.

Semi-Automatic & Automatic Models: Available in different configurations to suit production needs.

Multiple Nozzles: Can be equipped with single or multiple filling heads to increase efficiency.

How Does a Piston Filling Machine Work?

The operation of a piston filling machine is a seamless blend of mechanical and electronic engineering. Here’s a step-by-step breakdown of its functioning:

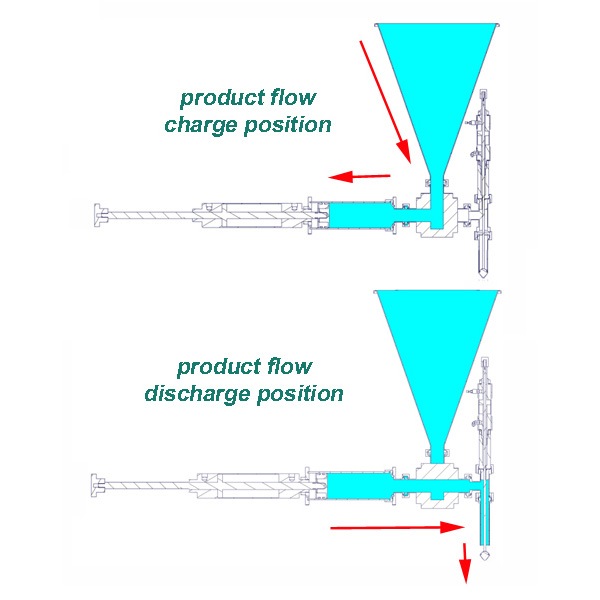

Product Intake: The piston retracts to create a vacuum within the cylinder, drawing the liquid or viscous product into the chamber.

Volume Measurement: As the piston retracts, sensors and control systems measure the volume of the product to ensure it meets the pre-set requirements.

Dispensing: The piston then moves forward, pushing the product out of the nozzle and into the container.

Cycle Repeat: Once dispensing is complete, the machine resets for the next cycle, maintaining consistent performance throughout production runs.

This process ensures that every container receives an exact amount of product, minimizing waste and ensuring product consistency—a critical factor in industries where precision is paramount.

Advantages and Disadvantages of Piston Filling Machine

- Mature and stable: filling technology from ten years ago, still in use today

- High precision filling: the error is usually less than ±1%.

- Wide range of materials: from liquids to pastes can be filled, including liquids with particles and suspended matter.

- Inexpensive: the price is acceptable compared to positive displacement pump filling machines.

- Limited filling range: limited by the piston cylinder, usually 1L piston cylinder can only fill 100-1000ML containers, the accuracy of containers below 100ml will deteriorate, more than 1,000 containers need to be filled several times with low efficiency.

- Cleaning is not very convenient: the piston cylinder has a hygienic dead corner, cleaning is not convenient (VKPAK piston filling machine is equipped with a cylinder cleaning function to greatly improve the cleaning efficiency).

- Wear and tear of piston cylinder parts: there are plastic parts in the piston cylinder, which will affect the precision and efficiency for a long time and need regular maintenance.