Auger fillers, as the name suggests, are a type of filling equipment based on auger metering. Auger fillers are the machine of choice for all fine powders or any product that has consistent size particulates such as talcum powders, flour, cake mixes and more. Auger powder-filling and dispensing equipment consists of a main hopper, stirring bar to keep the auger fed (even on powders that are not free flowing), and an auger that fits in a closeley fit cylinder. So long as the auger flights can be consistently fed, these machines can be extremely accurate. Since auger powder fillers are volumetric they do not actually weigh the product, except in cases where mated directly to a scale, but depend on accurate revolution counts of the auger (VKPAK's Auger Fillers are equipped with an in-line weighing and feedback system).

Auger Filler Working Principle

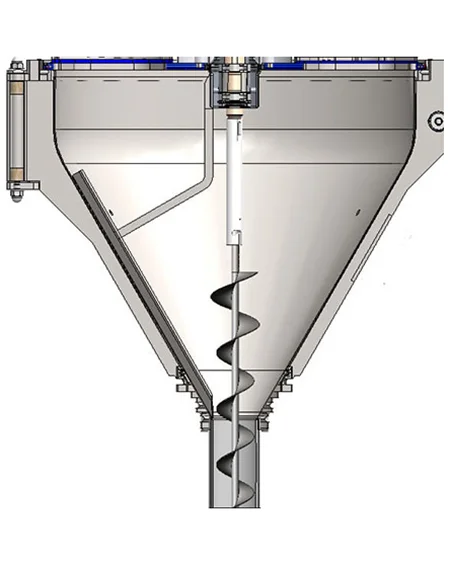

Powder stored in the hopper is fed into the auger tooling. The tooling consists of an auger, an agitator blade, and a funnel. Two motors mounted atop the filler offer separate precise control over the rotation of the auger and the agitator blade. The auger rotates to move the product down to the funnel, while the agitator blade works to prevent any product buildups or leftovers in the hopper.

The auger directs the product to the funnel, where it is dispensed into the container. The fill volume is controlled by adjusting the auger speed and the fill cycle. And then, the conveyor transports the filled container to the next station of the packaging line.

The agitator blade is operated and controlled separately. The agitator blade rotates in the opposite direction of the auger. It works to get rid of air in the powders, making the mixture more uniform.

Further, the agitator blade is designed to go all the way down to the funnel. This keeps rat-holing and cavitation from happening and ensures that the auger flights are always packed with the products.

The auger flights are spaced at the same distance. This ensures that each flighting pitch is filled with ingredients of the same bulk density and particle size. It helps achieve precise dosing as the auger rotates.

Auger Filler Videos

Advantages And Disadvantages of Auger Fillers

Auger fillers are the machines of choice for all dry products that have consistency of granule size and powders. In some cases auger filling equipment can be used as a depositor for moist products such as cooked rice and pastes. The biggest advantage of auger filling machinery is that the systems are relatively closed making auger fillers the ideal choice for very fine powders such as talcs, flour, and baking soda which tend to get airborne with other systems. Auger fillers are also capable of relatively high fill rates compared with net weight fillers and take up less floor space.

Advantages of Auger Fillers

- Fast, oftentimes usually at least 2-3 times faster than a single head net weight filler

- Relatively dust free, even on very fine powders that tend to get airborne easily. This is because auger fillers can be made so they are virtually closed off from the atmosphere, even during the dispense cycle.

- Can run free flowing powders as well as many less than free flowing products, so long as the product is consistent.

- Easy to integrate into a wide variety of packaging applications such as form and fill machines or applications for cans, bottles or boxes.

- Large range of filling capacity without need for change parts

- Very cost effective solution

Disadvantages of Auger Fillers

- Not reliably accurate for products with irregular shapes or densities

- Can damage products that cannot withstand compression

- Not particularly soft handling of product

The Best Powders for This Method

Before we look at the different types of tooling for different product characteristics, we first need to identify the type of product we are handling. There is a simple (but not completely foolproof) test for evaluating the flow characteristics of powders. If, when you insert a pencil into the top of a container full of power and then remove it, the hole immediately collapses in on itself, then the powder would be deemed to be free flowing. If, however, a perfect impression of the pencil remains, then it is deemed non-free flowing. Partial collapse might indicate a semi-free flowing powder.

Non-Free-Flowing Powders (E.G. Talc)

Semi-Free-Flowing Powders (E.G. Instant Coffee Powder)

A delicate or granular product might be damaged if large diameter compressive auger over-flights are used within the hopper section. In instances like this, an auger with parallel flights would be selected. Furthermore, a semi-free flowing powder might tend to dribble after the auger has stopped. In such cases, it is necessary to create a slight back pressure to retain the powder in the funnel by fixing a “drip washer” to the bottom of the auger, or adding a lip or crosswires/gauze to the bottom of the funnel. The correct solution varies with each powder.

Free-Flowing Granular Products (E.G. Table Salt, Granulated Sugar)

The Main Components Of The Auger filler

If you have a rough idea of the auger filling machine working principle, let's take a look at what parts enable the machine to work efficiently.

#1 Hopper

This component can vary in size, shape, and other designs. It generally comes in a split design. The split hopper comes with quick-release clamps, allowing operators to get inside the hopper for easy cleaning and tooling changeover.

Further, the upper part of the hopper features clear viewing glass. It allows operators to see what’s going on with the products inside the hopper.

Hoppers are usually made of 304 stainless steel. But in the case of corrosive environments, they can often be upgraded to 316 L stainless steel.

#2 Tooling

- An auger screw – Rotates vertically inside the hopper and feeds the product into the funnel.

- A funnel/tube – The outlet of the hopper in which the lower parallel flights of the auger screw doses.

- An agitator blade – Helps in feeding the powder product into the auger.

#3 Drive Assembly

In addition, since the auger screw rotates in the opposite position to the agitator blade, an independent agitator motor is required to control the speed and the number of revolutions of the agitator.

#4 Control System

The control panel should be user-friendly and have clear displays and buttons for easy operation. Some machines are built with a PLC-based touchscreen, allowing operators to perform tasks faster and with fewer steps.

How To Choose The Best Tooling

The size and type of the auger and funnel tooling is determined by a number of factors:

- Fill weight

- Dosing rate

- Accuracy

- Container neck opening

- Product characteristics

Consideration must also be given to the size of container that is being filled. For clean filling, the bottom of the funnel should be positioned as close to the top of the container as possible. If the container neck opening is 5cm ID, the funnel needs to be sized accordingly.

Another factor that must be considered when choosing suitable tooling is the product characteristics. Non-Free-Flowing Powders like talc may require an auger with larger diameter “over-flights” to push reluctant powder downwards to the smaller parallel section. The agitation mode can be controlled so that it stops between fills to avoid overworking and compacting the powder and if the powder is aerated coming into the hopper, the agitation mode can be changed to run continuously to assist with removal of the air. A larger hopper volume will aid de-aeration and homogenisation by allowing greater agitation/residence time.

Semi-Free-Flowing Products (e.g. instant coffee powder) that are delicate or granular might become damaged if large diameter compressive auger over-flights are used within the hopper section. In instances like this, an auger with parallel flights would be selected. Furthermore, a semi-free flowing powder might tend to dribble after the auger has stopped. In such cases, it is necessary to create a slight back pressure to retain the powder in the funnel by fixing a “drip washer” to the bottom of the auger, or adding a lip or anti-drip grid to the bottom of the funnel.

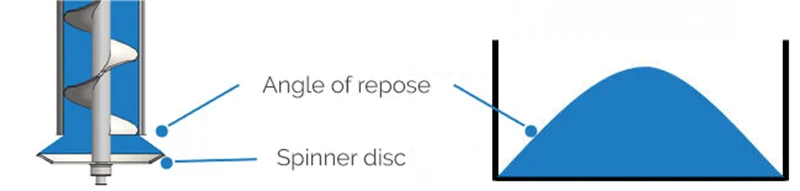

When filling Free-Flowing Granular Products like table salt or granulated sugar, a method of cutting off the powder flow is required. The usual method is to use a spinner disc; a saucer-shaped disc attached to the end of the protruding auger, designed to retain the product flow. All powders have an angle of repose, the angle at which a collapsing heap of powder will come to rest rather than continue to spread outwards. The spinner disc is sized to prevent the powder trickling over the edge of the disc once the auger has stopped. As the spinner disc throws the powder outwards, a simple collection cone funnels it into the container.