Introduction

This semi-automatic powder filling and capping machine includes semi-automatic auger filling machine and automatic four-wheel capping machine. Designed for metering and filling various kinds of powder and granular products into bottles, such as, Chinese / Western medicine powder, food powder and chemical powder etc. Supporting powder vacuum cleaner for dust removal to create a clean workshop.

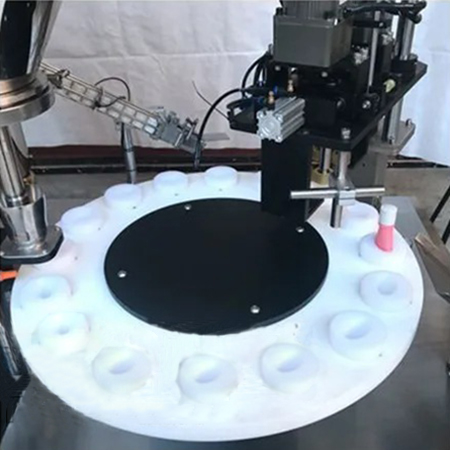

Workflow: manually put the bottle into the mold on the rotary table, the bottle automatically enters the filling station for filling (auger filling), after the filling is completed, the cap is automatically put on the cap, then the cap is automatically screwed on, and the packaged product is taken out manually.

The capping station can be customized according to the customer’s cap (replaced by an aluminum cap ROPP capper or chuck capper).

View VideoMain Features

1. Man-machine interface setting,PLC control, accurate loading.

2. Frequency conversion control, the production speed is arbitrarily adjusted, automatic counting.

3. Automatic stop function, no bottle no filling.

4. The disc positioning type filling is stable and reliable.

5. Made of SUS304 stainless steel, fully meet the requirements of GMP.

Parameter

| Product Name | Semi Automatic Rotary Powder Filling And Capping Machine |

| Measuring mode | Auger dosing model(Suitable for power and small granules products ) |

| Container size | φ30—160mm H50—260mm(can be customized) |

| Filling weight | 10-300g (can be customized) |

| Filling accuracy | ±1% |

| Filling speed | 20-40 bottles/min(depend on the material and weight) |

| Power supply | 110V/220V/380V |

| Total power | 2.3KW |

| Total weight | 500KG |

| Dimension | 2200 * 1000 * 1600 mm |

Details

Rotary powder fillers also have faster production speeds compared to inline powder fillers so they are suitable for large businesses requiring high production demands. They can have multiple in-feed lanes to accommodate various filling capacities.

Application

The powder filling machine is suitable for condiments, natural flavoring, food additives, flavors and fragrances, flour, milk powder, protein powder, solid drink, sugar, monosodium glutamate, pesticides, veterinary drugs, detergents, enzymes, feed additives, chemicals, new building materials and other powder (powder, superfine powder), mixing powder materials quantitative packaging, quantitative filling.