Introduction

Auger filling technology is most commonly used in applications requiring portioning and dispensing of powders, spices, coffee grinds, chemicals, flour, sugar, salt, baking mixes and other products with similar characteristics. Our powder filling machines are designed to accurately dispense your product by using a custom designed screw that will dictate how many revolutions are required to volumetrically achieve your desired weight.

This model is a semi-automatic powder filling machine, which can be used for bottles, bags, cans and so on. The metering screw can be adjusted according to the volume of the filling container for more efficient packaging.

View VideoMain Features

1. The whole machine is mainly made of stainless steel 304.

2. Hanging type hopper, easy to remove and wash without tools.

3. Servo motor control, optoelectronic switch control, packaging containers unlimited (bags, cans, bottles).

4. Can be equipped with feeding machine, easy to operate and save labor costs, greatly improve production efficiency.

Parameter

| Filling method | Screw metering (or electronic weighing) |

| Auger volume | 30/50L (can be customized) |

| Feeder volume | 100L (can be customized) |

| Machine material | SS 304 |

| Filling volume | 1-1000g(can be customized) |

| Filling accuracy | ±1% (different volume and material,accuracy will be little different) |

| Filling speed | 20-60 BPM |

| Weight | 200KG |

| Dimension | 1100*750*1750mm |

Details

Application

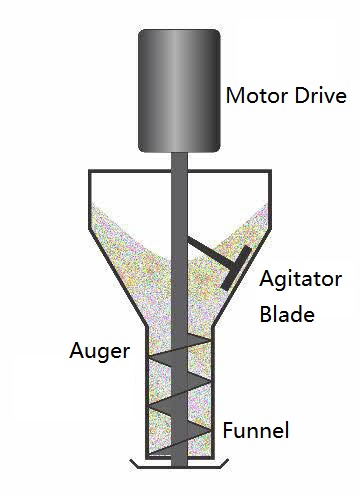

Auger filling machine working principle

After bulk materials are fed into the hopper, the auger drive keeps the auger rotating at a constant speed to move the materials down to the funnel.

The agitator blade is operated and controlled separately. The agitator blade rotates in the opposite direction of the auger. It works to get rid of air in the powders, making the mixture more uniform.

Further, the agitator blade is designed to go all the way down to the funnel. This keeps rat-holing and cavitation from happening and ensures that the auger flights are always packed with the products.

The auger flights are spaced at the same distance. This ensures that each flighting pitch is filled with ingredients of the same bulk density and particle size. It helps achieve precise dosing as the auger rotates.

Smart Touch Screen

- Color Interface

- Easy to operate

Openable Material Hopper

- Food Grade Material

- Washable

Electronic Scale

- Automatic Weighing Feedback

- Used For Filling Weight Correction

Detection Sensor

- Working With Material Feeder

- Automatic Feedback And Supplement

Screw for measuring

- Food Grade 304 Stainless Steel

- High Measurement Accuracy