Introduction

The rotary powder filling machine is developed and designed by our company on the basis of practice according to the needs of market development and conforms to the national GMP standard. The machine incorporates the latest European packaging technology concept, the design is more reasonable, more simple and more solid. Feeding, metering, filling, waste discharge and other work can be completed automatically. It is suitable for filling powder and granular materials, such as milk powder, monosodium glutamate, solid beverage, grape enamel, rice flour and so on.

Filling Speed: 60-80 BPM

View VideoMain Features

1. Automatic rotary powder bottle filling machine is designed for filling various kinds of powder products into bottles precisely with high speed, such as herbal powder, powdered medicine, seasoning powder, chemical powder etc. It is available to connect with plug insertion, capping machine and other equipment to complete the integral line system.

2. It is suitable for metering and filling a wide range of free flow or non-free flow powdered products.

3. It can reach the weight range from 1~5000 g by simply changing auger shafts without any tools.

4. Auger shaft is made of stainless steel, and based on one-piece integral processing to ensure the accurate of measurement. Metering tolerance is within ±1%.

5. All material contact parts are made of stainless steel (Standard type 304 / Optional type 316).

6. Rotary auger filling system operates continuously with bottles guided through movements of starwheel components, to finished lead-in, lift-up, vibration, fill-in etc. All movements during production work fast and smoothly to reach the high speed output.

7. With self- diagnostic device, rotary auger filling system is able to stop operations automatically while any error occurs. Meanwhile, it will trigger alarm and show the event on HMI touch screen.

8. With bottle detection device, it is able to stop filling while there has no bottle. It also can stop operation while bottle jammed occurs.

9. HMI touch screen for operational control.

10. Customized design and fabrication of the production line system is available.

Parameter

| Product Name | Automatic Rotary Powder Bottle Filling Machine |

| Container size | Φ30-160mm, H50-260mm |

| Filling weight | 10-5000g (can be customized) |

| Filling accuracy | ≤500g, ≤±1% / >500g, ≤±0.5% |

| Filling speed | 60-80Bottles/min |

| Voltage | 3P AC208-415V 50/60HZ |

| Air compression | 6KG/cm2 0.05M/3/min |

| power | 2.3KW |

| Machine weight | 390KG |

| Outline dimension(mm) | 2000*1070*2120 |

| Hopper capacity | 50L/hopper |

Details

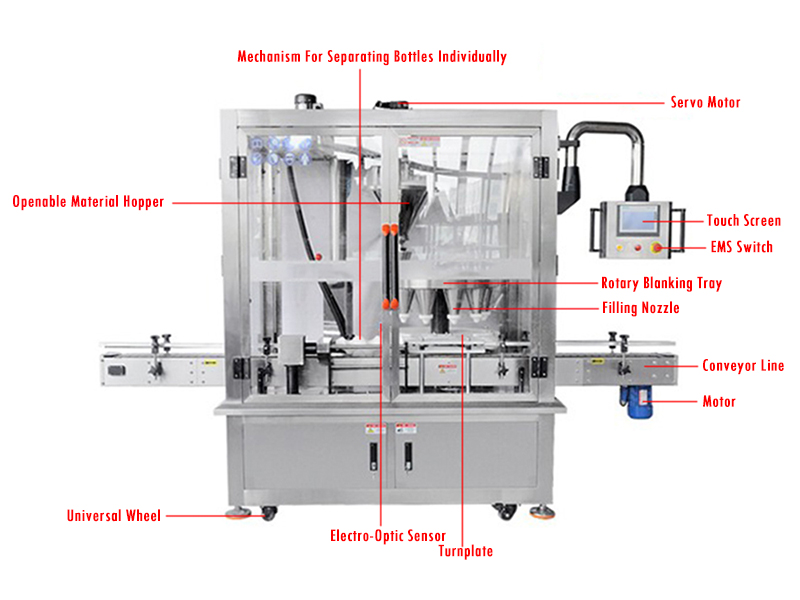

1. Smart Touch Screen: color interface and easy to operate

2. Openable Material Hopper: food grade material and washable

3. Rotary Feeding Mechanism: high filling accuracy and speed, graetly improve working efficiency

4. Mechanism For Separating Bottles Individually: screw bottle splitter, separating bottles quickly, strong versatility

Application

High accuracy powder little bottle rotary filling capping machine is suitable for automatic filling of various powder products, such as spice powder, chili powder, milk powder, protein powder, seasoning powder, onion powder, ginger powder, etc.