Introduction

The powder filling machine is designed in accordance with the national GMP standard. It is suitable for filling powdered materials such as milk powder, glucose, protein powder, cocoa powder, coffee powder, rice powder, solid drink and so on.It can be used alone or connected to production lines, and can be combined with capping machine, labeling machine, ink jet printer, etc., save labor and increase output.

The auger filler machine is the foundation of the powder product line. Always reliable and built to last, VKPAK’s auger filling machines are the pinnacle of the industry. Automatic auger fillers are designed for complete, continuous container transport, positioning, filling, and discharge to the next stage in the packaging process. VKPAK’s completely automatic auger filling machines are the solution to your demanding filing requirements.

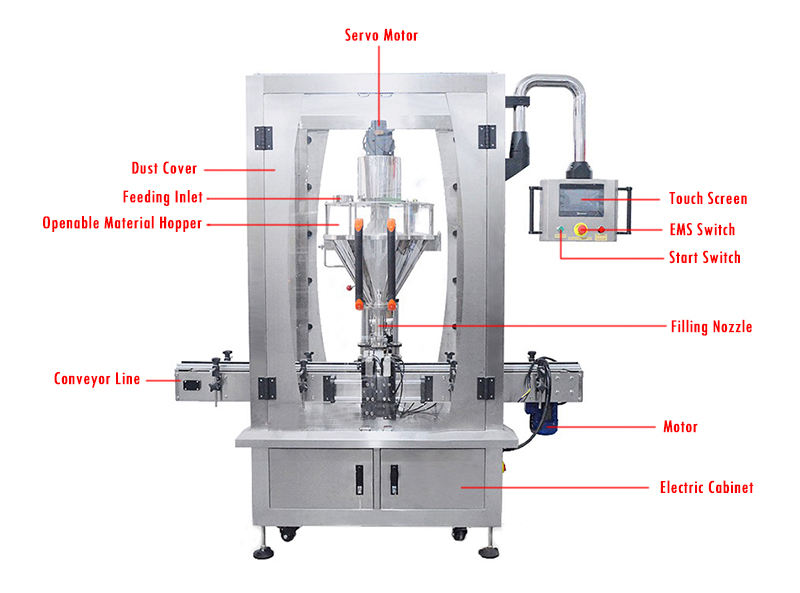

View VideoThese fillers have a touch screen that is linked to a PLC (Programmable Logic Controller) that operates the machine. The machine operating program gives the operator the ability to make fine adjustments to the machine as needed during a shift. The logic continuously monitors the machine for correct operation along with built in safety checks.

Main Features

1. The entire machine is constructed from stainless steel, meeting the packaging requirements for anti-corrosive chemical products, among others.

2. The touch screen man-machine interface ensures stable operation, anti-interference capability, high weighing accuracy, and convenient, intuitive operation. Packaging weight is continuously adjustable, and the operational status can be changed at any time for convenient use.

3. The filling mechanism utilizes a servo motor-driven screw auger, providing precise positioning, high precision, rapid speed, substantial torque, extended lifespan, and adjustable speed. It offers excellent stability and other advantages.

4. The mixing process employs a maintenance-free geared motor made in Taiwan: low noise, long lifespan, and a lifetime warranty.

5. Designed as a feedback weight-tracing system, it overcomes issues related to variations in weight caused by changes in material specific gravity.

6. The fully sealed air barrier, glass-stainless steel, side-opening composite material hopper allows clear visibility of material movement, prevents dust leakage, and includes a filling outlet with a suction collection device to preserve the workshop environment.

7. The machine features interchangeable screw attachments, adapting to a variety of materials, from ultra-fine powder to large particles.

8. The machine can achieve the automatic filling of powder materials, automatic capping or sealing, and complete automation control.

Parameter

| Product Name | Automatic Single Head Servo Auger Filler Machine |

| Filling weight | 10-5000g (can be customized) |

| Container size | Φ30-160mm, H50-260mm |

| Filling speed(B/H) | 30-50 Bottles/min(Depend on different material and filling volume) |

| Filling accuracy | ≤500g, ≤±1% / >500g, ≤±0.5% |

| Air compression | 6KG/cm2 0.05M/3/min |

| Power | 2.3KW |

| Voltage | 110V/220V/380V |

| Hopper capacity | 50L/hopper |

| Machine weight | 350KG |

| Outline dimension(mm) | 2000×1070×2120 |

Details

- 50L side opening hopper, easy to clean.

- Packaging powdery in 10-5000g bottle, change auger for different weight.

- Servo motor drive the auger, got high accuracy.

- Have one stir on the hopper, assure the powder fill in the auger.

- Reasonable mechanical structure, easy to change size parts and clean up.

- Through changing accessories, the machine is suitable for various powder products.

- We use famous brand electric, more steady.

Application

Automatic powder auger filler machine is an excellent powder filling machine, known for its versatile properties ideal for filling fluffy, non-free flowing and sticky powder into the containers. Such as milk powder, coffee powder, spice powder, protein powder, nutritional powder, medicine powder, meal replacement powder, etc.