Introduction

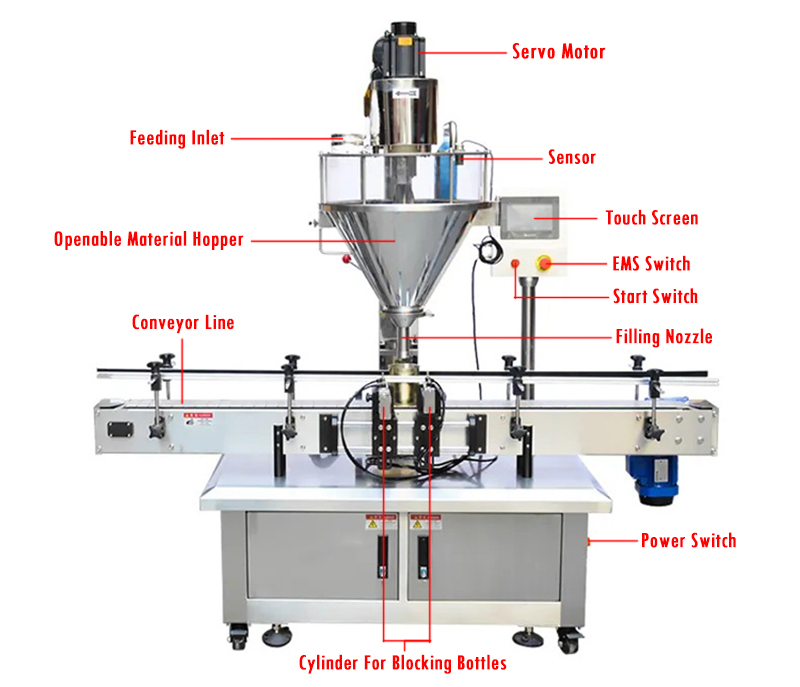

This machine is a complete, economical solution to your filling production line requirements, measuring and filling powder and granule. It consists of the filling head, an independent motorized chain conveyor mounted on a sturdy, stable frame base, and all necessary accessories to reliably move and position containers for filling, dispense the required amount of product, then quickly move the filled containers away to other equipment in your line (e.g., cappers, labelers, etc). It fits more to the fluidic or low-fluidity materials, like milk powder, albumen powder, pharmaceuticals, condiment, solid drink, white sugar, dextrose, coffee, agriculture pesticide granule additive and so on.

With the assurance that the machine will run smoothly, be durable, and have reliable accuracy, this model is the lowest cost among the automatic powder filling machines offered by VKPAK.

View VideoThe machine has automatic quantitative filling, automatic correction error, material level control, automatic material clearing, calculation and other functions. With high sensitivity, high precision and high reliability, it can meet the filling requirements of different specifications.

The full automatic quantitative powder filling machine is designed for saving time on adjusting and testing machine, it can filling powder accurately by entering a certain filling volume. The PLC control method makes it easy to operate, the high speed working efficiency is ideal for medium or large scale production. It can work with the automatic capping machine and labeling machine to form a complete production line and realize high speed packaging work.

Main Features

1. All stainless steel structure, easy to disassemble and clean.

2. High precision servo motor control filling, accurate metering.

3. A variety of product adjustment parameters formula can be stored, ready for later use.

4. The replacement of spiral accessories can adapt to a variety of materials such as ultra-fine powder to small particles.

5. Touch screen PLC control, easy operation.

6. Can be applied to food, medicine and corrosive chemical raw materials. Centralized dust removal, no dust pollution in the workshop.

Parameter

| Product Name | Auto Low Cost Powder Bottle Filling Machine |

| Container size | φ50—200mm H50—350mm(can be customized) |

| Filling weight | 10-5000g (can be customized) |

| Filling accuracy | ≤500g, ≤±1% / >500g, ≤±0.5% |

| Filling speed | 25-45 bottles/min(depend on the material and weight) |

| Voltage | 110V/220V/380V |

| Air compression | 6KG/cm2 0.05M/3/min |

| Power | 2.3KW |

| Machine weight | 350KG |

| Outline dimension(mm) | 2000*800*1800mm |

| Hopper capacity | 50L/hopper |

Details

- The touch screen control panel is more convenient to adjust working parameter like filling volume, working mode. The visual working parameter can help you watch the machine in real time.

- With large hopper and large motor, the machine can work stably, and more convenient to pour filling materials, improves working efficiency.

- Equipped with chain conveyor belt, it is good for transporting bottle smoothly, the width and length can be customized accoring to production need.

- The high quality electric eye can detect passing by bottles and control the machine to start work or not. This can prevent from missing bottles and improve filling accuracy.

- Equipped with weighing device, it can be used to control filling volume after dismantling conveyor belt, offer multiple kinds of working mode and make the production be flexible.

Application

This powder filling machine is widely used to filling powder products like amber powder, diatomite powder, milk powder, matcha powder. This machine gets a lot of popularity from manufactures come from food, cosmetics industries.