Introduction

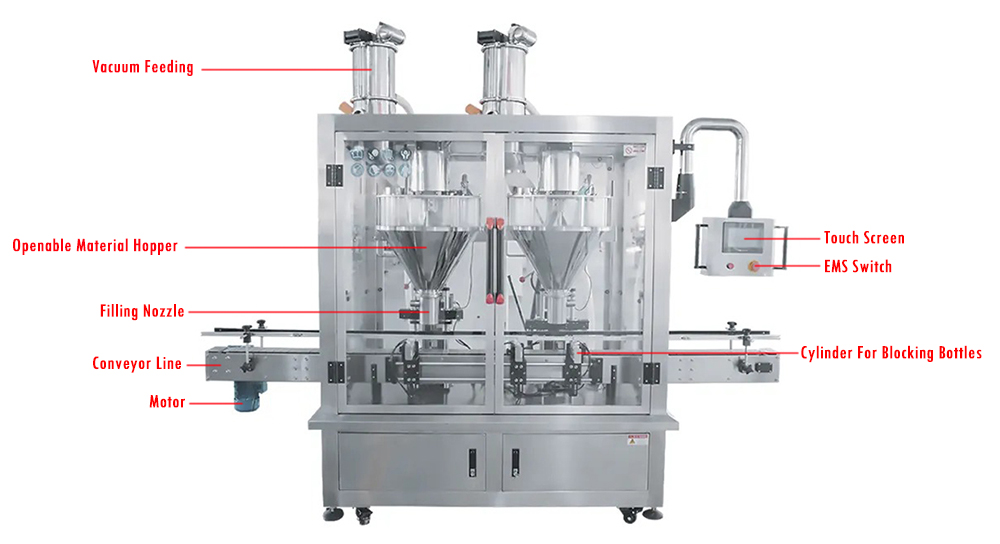

Double heads automatic powder filling machine is suitable for all kinds of powdered, ultrafine powdered or powder granular material, canned, bottled, barreled. Such as: milk powder, rice flour, protein powder, cocoa powder, coffee powder, powdered drugs, chicken powder, chicken, additives, sugar, dyes, flavors and spices, etc.

VKPAK offers two types of dual-head powder filling machines, one with dual heads equipped with equal-sized auger screws, configured with dual heads for efficiency; the other with dual heads equipped with different-sized auger screws and equipped with real-time weighing feedback for improved efficiency and accuracy.

View VideoType One: Auger screws of the same size

Main Features

1. Twin-screw head filling, main filling and supplementary filling; Servo and pneumatic system control tank and horizontal moving tank, accurate positioning and fast speed, stable performance and high accuracy;

2. Changing screw can measure different weight and precision;

3. Adopted 1.5mm thickness 304 stainess steel for the whole frame;

4. Organic glass is made of imported acrylic, with a thickness of 8-10mm, high-end atmosphere;

5. There are two weight sensors under the container tray, fast and slow filling according to pre-set weight, ensure the accuracy of canning, have the function of weight elimination at the end of equipment configuration;

6. All 304# stainless steel structure, horizontal opening transparent container, can be opened for cleaning without tools, easy for cleaning;

7. Equipped with dust removal device and negative pressure pipe, it can effectively suck away the raising powder in the filling process and effectively protect the workshop environment.

Type One Parameter

| Product Name | Automatic Double-Head Powder Bottle Filling Machine |

| Filling nozzle | 2(Can be customized) |

| Container size | Φ30-160mm, H50-260mm |

| Filling weight | 100-5000g (can be customized) |

| Filling accuracy | ≤500g, ≤±1% / >500g, ≤±0.5% |

| Filling speed | 30-50 Bottles/min(Depend on different material and filling volume) |

| Voltage | 220V |

| Air compression | 6KG/cm2 0.05M/3/min |

| Power | 2.3KW |

| Machine weight | 400KG |

| Outline dimension(mm) | 2500×1100×1800 |

| Hopper capacity | 50L/hopper |

Type Two: Auger screws of the different size

Main Features

1. Single row double head filling, main filling and supplementary filling, ensuring high canning accuracy.

2. Servo and pneumatic systems control the support and horizontal movement of the tank, ensuring accurate positioning and fast speed.

3. Servo motor and servo drive control screw, stable performance and high accuracy.

4.All stainless steel structure. The horizontally open material box (polished inside and outside) is very convenient for cleaning.

5. PLC control, touch screen human-machine interface display, easy to operate.

6. A weighing system with high reaction speed ensures high canning speed and precision.

7. The filling head is equipped with a handwheel to adjust the height, making it easy to achieve external canned filling.

8. Equipped with dust removal device and connected to negative pressure pipeline, there is no dust pollution environment.

9. Horizontal linear structure, small footprint, easy to clean.

10. Fixed screw installation structure ensures no metal pollution during canning.

11. Equipped with a central control system for the entire line.

Type Two Parameter

| Product Name | Automatic Double-Head Powder Bottle Filling Machine |

| Method of measurement | Double screw filling head measurement |

| Canning weight | 100 - 2000g |

| Container size | Φ60-135mm; H 60-260mm |

| Canning accuracy | 100-500g, ≤±1g; ≥500g,≤±2g |

| Filling speed | Above 50 BPM (#502 cans), above 55 BPM (#300 ~ #401) |

| Power source | 3P AC208-415V 50/60Hz |

| Overall power | 3.4 kw |

| Machine weight | 450kg |

| Compressed air | 6kg/cm 0.2cbm/min |

| Machine volume | 2650×1040×2300mm |

| Tank volume | 50L(main) 25L (supplementary) |

Details

Application

It is suitable for automatic filling of various powder products, such as Milk powder, protein powder, nutritional powder, coffee powder, medicine powder, chemical powder, meal replacement powder, etc.