Introduction

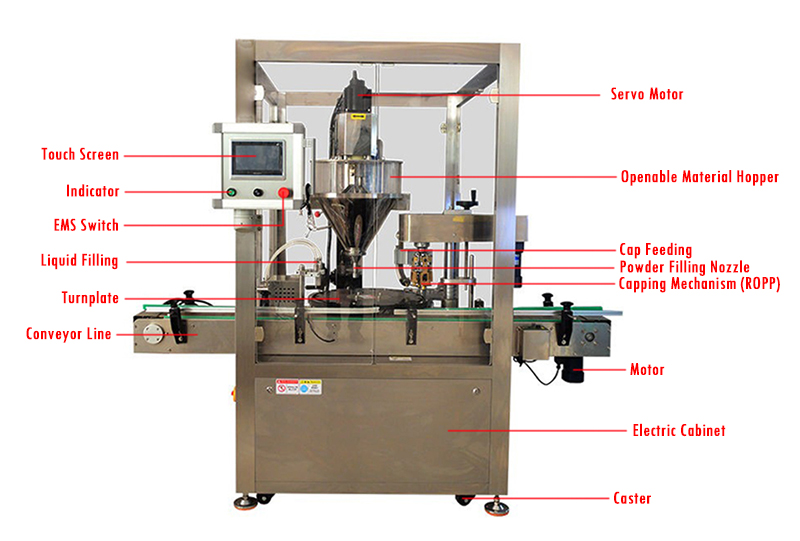

The monoblock powder filling capping machine is suitable for packing powder into bottles, which can automatically complete the actions of filling, feeding, plugging, capping, etc. Equipped with the magnetic pump filling system and screw filling system, it can fill liquid and powder at one time or separately, ensuring high filling precision. And this machine meets GMP requirements.

1. Man-machine interface, easy and convenient operation, PLC control.

2. Variable frequency control, production speed arbitrary regulation, automatic counting.

3. Automatic shutdown function, no bottle no filling.

4. High-precision cam indexing control and positioning precision.

5. Using stainless steel manufacturing, fully in line with the GMP requirements.

The capping station can be customized according to the customer’s cap (replaced by an aluminum cap ROPP capper or chuck capper).

View VideoMachine is suitable for automatic bottle filling, feeding caps and capping of vairous medicine, food, beverage, chemical powder, like milk powder, soy milk powder, sesame paste, flour, soy flour, starch, pharmaceutical powder, pesticide powder, coffee powder, seasoning powder, allspice powder, pepper, etc.

Main Features

1. Adopts auger type metering method with liner conveyor system for filling powder into bottles/cans.

2. Auger tool is one-piece manufactured of stainless steel.

3. Bottle auto-positioning device and filling vibration device systems are available to be added on.

4. Automatically stops when an error occurs. Stop filling automatically when there’s no bottle, and when bottle jammed occurs, no air supply or insufficient air pressure etc., the machine (system) will also stop automatically.

5. The machine is available to be system-linked with material supply system.

6. Transmission system of the filling machine is driven by servo motor for high accuracy and stability.

7. HMI touch screen for operational control.

Parameter

| Product Name | Automatic Monoblock Powder Filling And Capping Machine |

| Voltage | 220V 50HZ |

| Power | 3KW |

| Measuring method | Screw auger measuring |

| Filling volume | 5-500ML or 5-500G |

| Filling speed | 20-60BPM |

| Filling accuracy | ±1% |

| Bottle size | Customizable |

| Cap diameter | Customizable |

| Outline dimension | 3000*1900*1800MM |

| Weight | 500KG |

Details

This all-in-one machine researched and developed on request of oversea customers integrates powder-filling and cap-putting functions. It can perform filling, cap-puttingand cap-pressing (cap - screwing) functions. It has compact structure and is easy to operate.

2. The whole machine is designed appropriately. It is convenient for changing different kinds of packing products and cleaning.

3. Adopting touch pannel. Working condition, operation instructions can be seen in both Chinese and English. Simply and intuition. Packing weight can be adjusted, operation manner can be transformed arbitrarily. It will give an alarm when meeting malfunction.

4. Controlling part adopts PLC. Anti-interference, working smoothly.

5. Filling adopts servo drive, accurate, high precision, long operating life. Its speed can be set. Stiring adopts Taiwan mantenance-free motor.

6. Replace screw attachments, it is suitable for the packing of products from fine particle to ultrafine powder materials. We can add aspiration and vibration devices according to different kinds of materials.

7. Various products formulation parameters can be stored, can be called up anytime

8. The model is made in according with national GMP, QS health certification requirements.

Application

Designed for metering and filling various kinds of powder and granular products into bottles/cans, such as, Chinese / Western medicine powder, food powder and chemical powder. etc.

Range of filling and metering: 1-500g. (Easy to change capacity by simply changing the auger).