Introduction

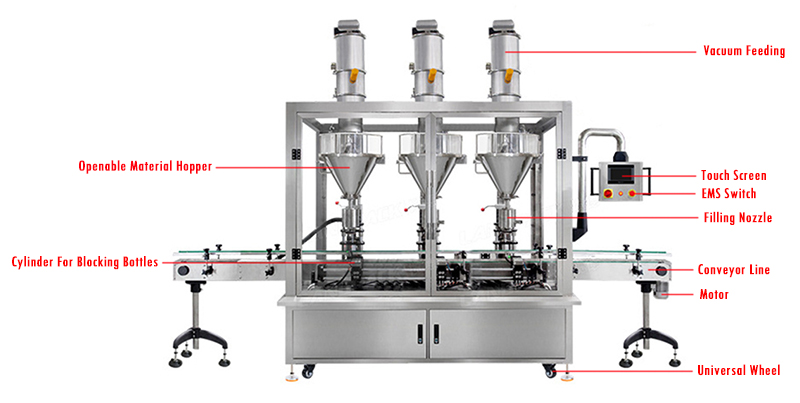

Our automatic three head auger powder filling machine(Dust cover is optional) is a compact model applied to dose all kinds of dry powder both free flow and non-free flow powder into bottles, cans, jars etc. The filling was controlled by PLC and servo drive system featured with high speed and good accuracy. Bottles and cans are transported by conveyor belt combined with gating system. There is a photo eye sensor for bottles detection so as to achieve bottle-fill, no-bottle no-fill. Automatic bottle positioning – filling – releasing, optional vibration and elevation. Featured with compact design, stable performance, easy to operate and good cost performance!

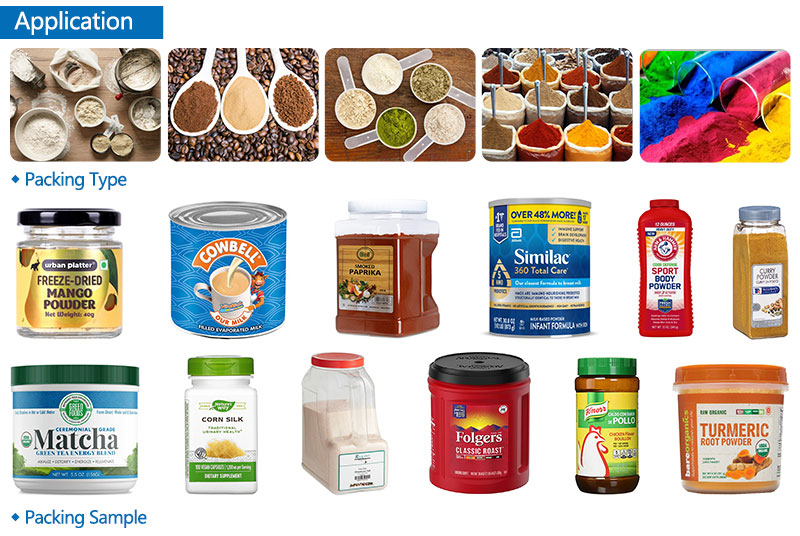

View VideoApplicable to food, medicine, daily provisions and other industries powdery materials.

Such as milk powder, glucose, protein powder, cocoa powder, coffee powder, rice powder, solid beverage powder, such as powder, super fine powder materials.

Main Features

1. Through the way of auger filling, it can fill powder precisely.

2. With PLC control panel, it is easy to set or adjust parameters. Language of panel can be customized.

3. Quantity of filling heads can be customized as your need.

4. Replace the different sizes of auger, this machine can adapt to various materials such as ultrafine powder to small particles.

5. Fully stainless steel structure, split or open-type transparent hopper, can be cleaned without special tools.

Parameter

| Product Name | Auto 3 Heads Powder Bottle Filling Equipment |

| Machine voltage | 380V 6KW |

| Filling range | 50-5000g (Customizable) |

| Filling nozzle diameter | Custom |

| Filling head quantity | 3 |

| Machine size | About 2800*1050*2300mm |

| Package size | About 2590*1030*2230mm |

| Net weight/Gross weight | About 600kg/905kg |

Details

1. Equipped with touch screen control panel, the visual working date is more convenient to adjust the machine in real time, different operation language can be customized as need.

2. Multiple filling heads can be customized as production need, the size of filling nozzle will be customized according to bottle opening mouth, angle and height of filling nozzle by the rotary handle and knob.

3. Designed with the dust-proof component, the height can be adjusted by the rotary knob, this component can ensure the production quality.

4. The electric eye is used to detecting passing by bottles, control the machine to start the filling work automatically. With this, the machine can realize the automated work.

5. Using high-quality machine accessories, and the reasonable circuit design ensure the stable operation of the machine, this is also easy to troubleshoot circuit problems.

Application

For applications with the most demanding speed and accuracy requirements, the three head auger filler provides you with unsurpassed performance. Use of directly coupled advanced specification servo motors gives the optimum control and performance of filling accuracy.

Suitable for all kinds of powder, such as spice powder, seasoning powder, milk powder protein powder, nutritional powder, grain powder, washing powder, garlic powder, pest powder, chili powder, etc.