Introduction

The semi auto ultrasonic tube filling sealing machine is an advanced device designed for seamless operation in the domain of tube sealing. It leverages ultrasonic technology and has a rapid melt adhesive effect for efficient and strong seals on plastic and aluminum plastic tubes. Key features include automatic tube orientation, filling, sealing, date printing, trimming, and tubes output. It has a sealing diameter of 5-50mm, with a production capacity of 20-25 tubes/min. This machine is manufactured in China and available for export globally.

Sealing method: Ultrasonic sealing

Applicable tube materials: plastic tubes, laminated tubes

Speed: 20-25 pcs/min

It can fill and seal the plastic tubes and plastic-aluminum laminated tubes. It is widely used in the cosmetic, cream, lotion, medicine, lubricants, adhesive and shoe polish, food industries.

View VideoWorking Video

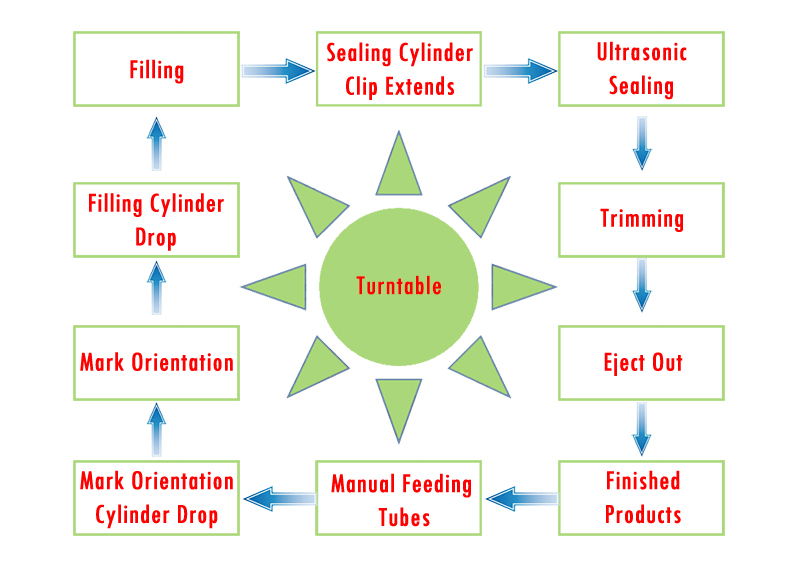

Working Process

- Manual Tube Feeding

- Mark Orientation Cylinder Drop

- Mark Orientation

- Filling Cylinder Drop

- Filling

- Sealing Cylinder Press

- Ultrasonic Sealing

- Trimming

- Finished Product Ejection

Parameter

| Model | VK-TFS-006U |

| Frequency | 20kHz |

| Power | 2600W |

| Power supply | AC220V/110V |

| Filling Range | A. 6-60ml B.10-120ml C. 25-250ml D. 50-500ml |

| Filling Accuracy | ±1g |

| Capacity | 20-25pcs/min |

| Tube Diameter | 13-50mm |

| Tube Height | 70-250mm |

| Working Pressure | 0.6 MPa |

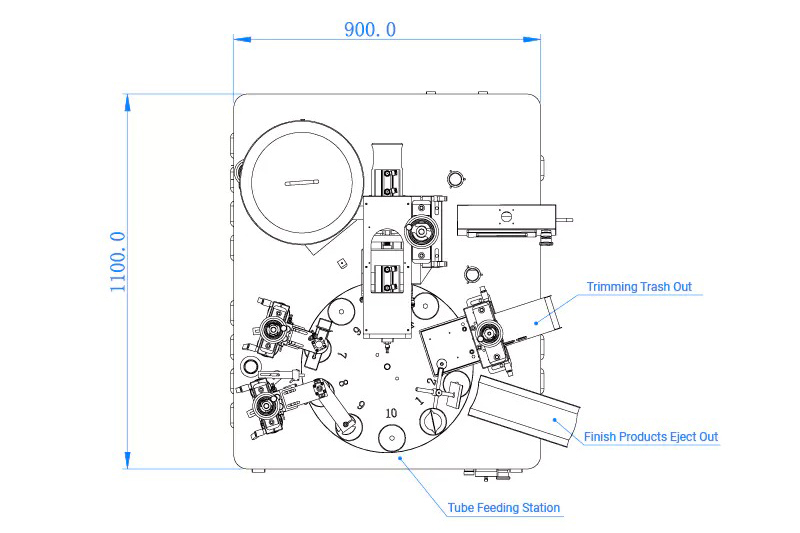

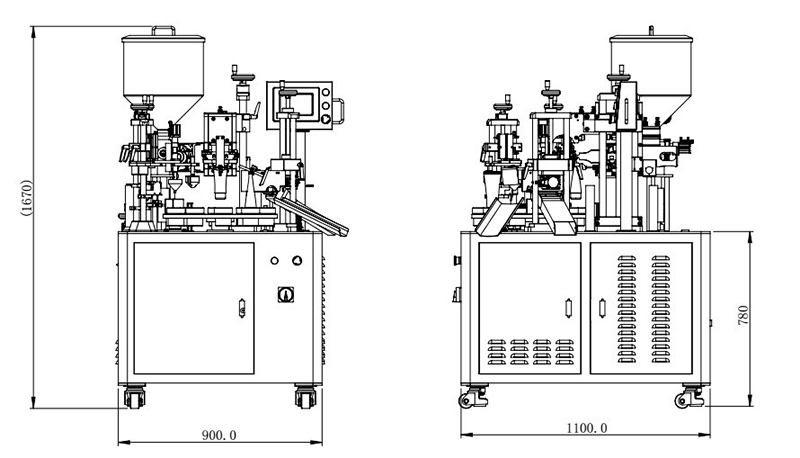

| Size | L900*W1100*H1600mm |

| N.W/G.W | 350Kgs/400Kgs |

Main Features

1. Manually tube feeding automatic registration mark identifying, filling, sealing with coding, end trimming, tube out feeding.

2. Cam indexing system could position precisely for ten working stations.

3. Adopts ultrasonic sealing technology, no need warm up time, more stable and neat sealing, no distortion and low reject rate less than 1%.

4. Independent R &D for digital ultrasonic automatic tracking electrical control box, no need manual adjust the frequency, with power auto compensation function, avoiding the reduction of power after long time use. Could freely adjust the power based on tube material and size, stable and minimum the fault rate, extend the life span than the normal electrical box.

5. PLC with touch screen control system with alarm system, could directly view the alarm information on the touch screen, could locate the problem and solve immediately.

6. Made of 304 stainless Steel, acid and alkali resistance, corrosion resistance.

7. No tube, no filling, no tube, no sealing function, reducing the machine and mould loss.

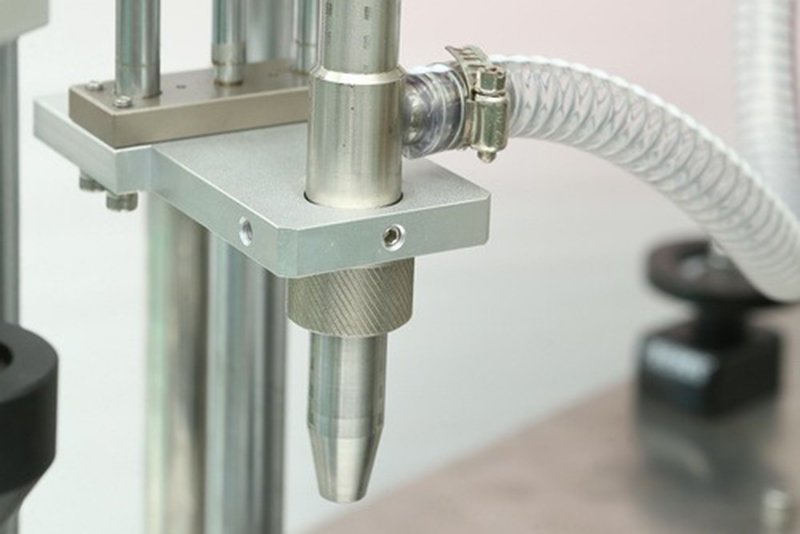

8. Adopts Anti-dripping filling nozzle.

Drawing

Machine Options

- Auto refill pump

- Heating and mixing system for material hopper

- Air blow system for high viscous and sticky material

- Safety door

- Industrial water chiller

- 316L Stainless Steel Contact parts

Advantages

1. It adopts Ultrasonic sealing machine, good for difference products, Such as food, medical, cosmetic products. It will not hurting the products.

2. Overload protection, phase separation protection, power-fail protection.

3. Large Ultrasonic output power to ensure the sealing quality of various tube size and material. No need preheating before sealing and no need working with industrial chiller.

4. With tube end trimming

5. Easy change working mold for difference tube diameter

6. Adjustable tube length

7. Machine include a gear pump filler( Good filling precision+- 1%)

Images

- Easy to operate and maintain.

- Automatic positioning, filling, sealing, cutting and trimming, printing code in one time.

- Stainless steel machine body, strong and beautiful looks,

- Sealing mould can be customized according to customer requirements. Can seal many size of tubes.

- Ultrasonic Sealing Machine power source for the pneumatic, working steady, not easy to damage, customers can rest assured use.

- Ultrasonic frequency can meet international standard, no harmful to human being or environment

- Can be work in time, not need wait the heat time.

Application

This tube filling and sealing machine is an ideal machine for use in the pharmaceutical, chemical, cosmetic, foodstuff and other light industries. This tube filler can be used to fill all kinds of semi-viscous and viscous products into soft plastic or flexible compound tubes.

Tube Tail Trimming Shape

| Ultrasonic System | Automatic Frequency Tracing |

| Benchmarking Electric Eye | Panasonic, Japan |

| PLC | Coolmay,CN |

| Electric Relay | Omron, Japan |

| Touch Panel | WEINVIEW,China Taiwan |

| Inductive Switch | SICK, Germany |

| Air Cylinder | AirTAC,China Taiwan |

| Solenoid Valve | AirTAC,China Taiwan |

| Motor | zhongdamotor CN |

| Partitioner | JOUDER,China Taiwan |

| Frequency Converter | DELTA,China Taiwan |

| Stepper Motor | Leadshine,CN |

Positioning device at color mark tracking

Panasonic mark sensor

Brand: Pannasonic

Original: Japan

Tube Orientation

(R · G · B) LED in high-precision mode, high resolution of R / G · B ratio of reflected light through high-resolution by using built-in 12bitA / D converter can achieve high resolution of 1 / 4,000 Accuracy judgment, determine the color of the color. But also can effectively detect the color around those with patterns and patterns such as film.

More stable in color mark

Minimum the tube deformation influence to the accuracy

Adopts Anti-dripping filling nozzle

- Widely used for cream, liquid, lotion and gel filling

- Anti-drip filing nozzle

- Suitable for high viscosity materials filling

- 304 stainless stell filling nozzle

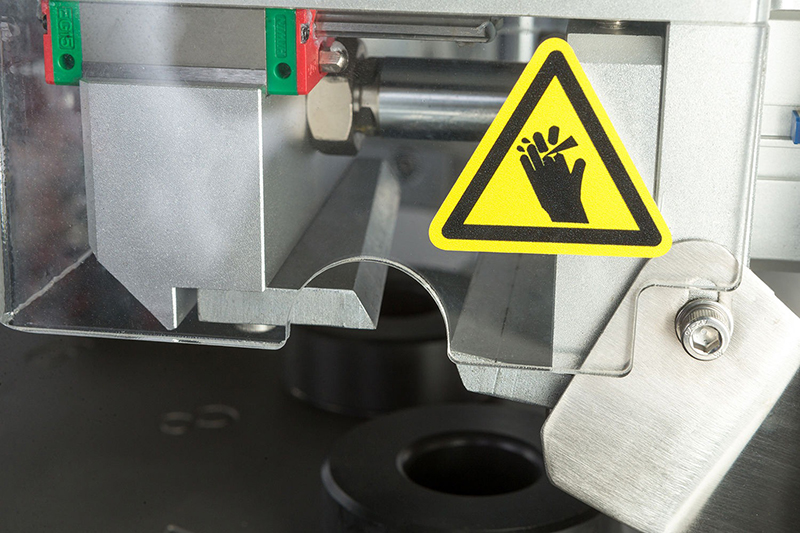

Ultrasonic Sealing Horn

- Downer horn with postition structure

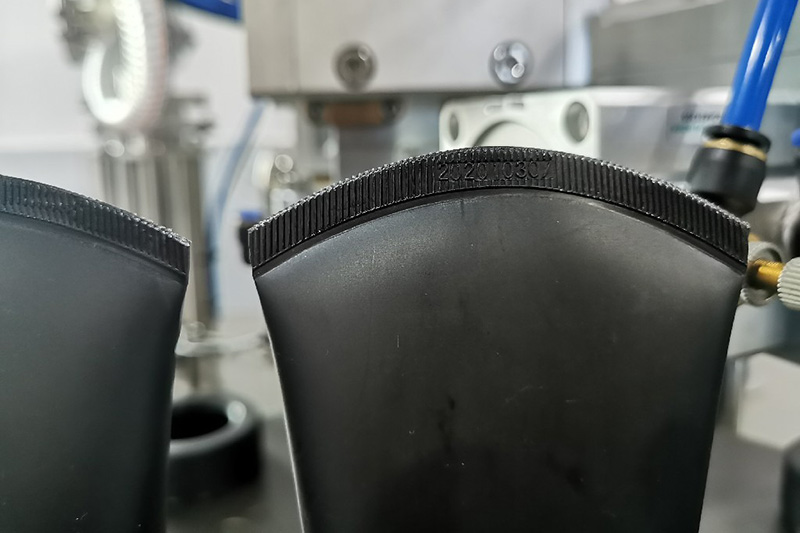

- With date coding function, can sealing the tube and printing date in the same time

- Long service life

- Rigid oxidation horns, durable , smooth tail colosure, clear stripes

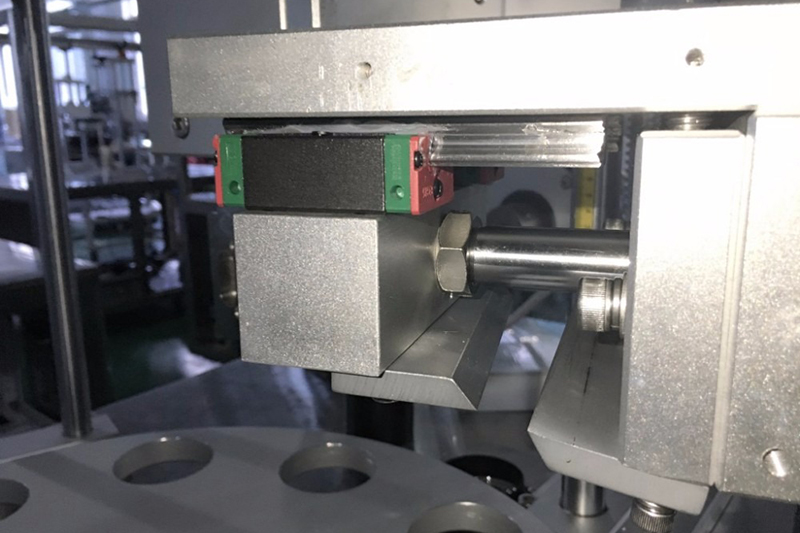

High Quality Tube Trimming Cutter

Name: Two-way cutter

- For tube end trimming

- Made by 304 stainless steel

- No burrs after trimming

- More durable

Tube Output

The tube output automatically after sealing and trimming