Introduction

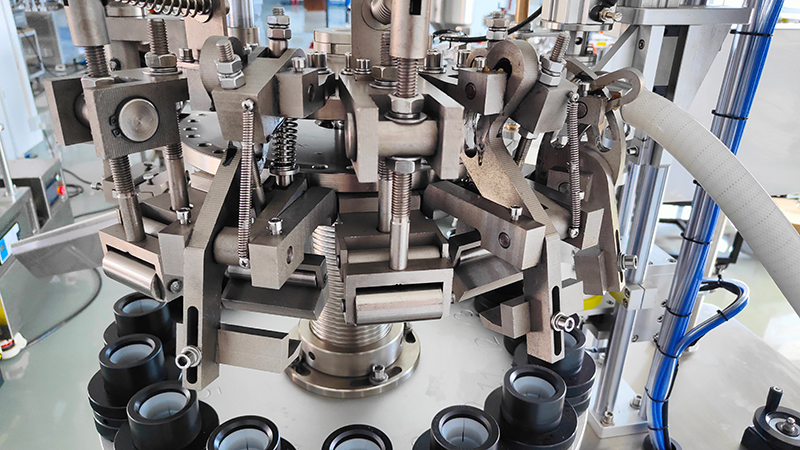

VK-TFS-006A aluminum tube filling and sealing machine speed at 30 tubes/min is mainly used for aluminum and metal tube filling and sealing. It has been widely used in the fields of cosmetic, food and chemical etc. It is pneumatic controlled, with 1 filling head and tube tail folding stations. It has total 16 positions for filling and sealing. And materials such as paste, adhesives, AB glue, epoxy glue, skin cream, hair dye, shoe polish, toothpaste, RTV silicone etc., are all applicable.

Sealing method: Folding Sealing

Applicable tube materials: Aluminum tubes, metal tubes

Speed: 25-35 pcs/min

View VideoThe machine, with a controllable filling volume or quantity, is featured with a reliable performance performance. The machine is suitable for the filling of metallic tubes of any type because the tube-holding base can be easily replaced in purpose. A perfected and reliable sealing can be reached.

Our monoblock is equipped with advanced PLC controls, making it easy to operate and control. Its high level of automation and precision make it the perfect choice for small and medium-sized businesses looking to enhance their packaging process.

Working Video

Parameter

| Model | VK-TFS-006A |

| Weight | 350Kg |

| Power | 220V/50Hz |

| Filling Quantity | 1-5g/5-25g/20-75g/75-250g |

| Suitable Filling Material | Aluminum and metal tube |

| Date Printed | 1-2 rows(numbers & letters) |

| Dimension | 1500*700*1800mm |

| Motor | 1.5Kw |

| Capacity | 25-35 tubes/min |

| Maximum Tube Dia. | 60 mm |

| Additional Function | Air pressured tank Diving filling function |

Main Features

1. High-tech product which successfully developed and designed by adopting advanced technology from abroad and strictly meet GMP requirement. PLC controller and color touch screen are applied and made it possible for programmable control of the machine.

2. The surface panel is made of stainless steel panel, with beautiful appearance and durable lifetime.

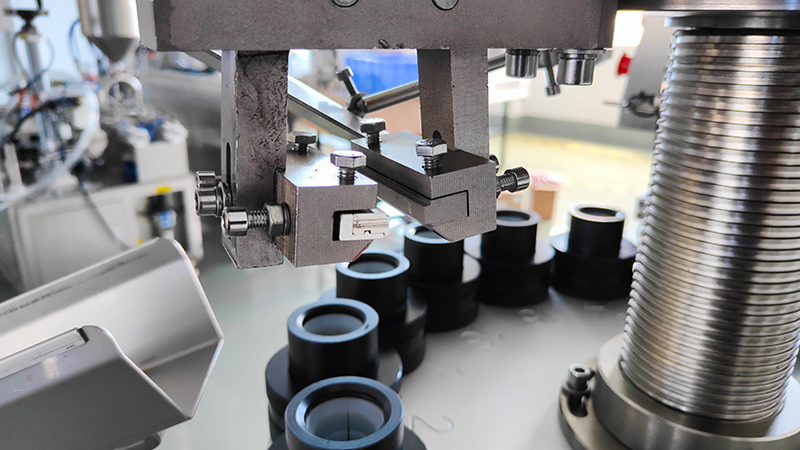

3. Tube marking identification, filling, folding, sealing, code printing and finished product output all conducted by a fully auto control system.

4. With easy and quick adjustment, it is suitable for using multiple kinds of metal tubes for filling.

5. The part contacting materials is made of 316L stainless steel, clean, sanitary and conforming to GMP for medicine manufacture.

6. Overload protection provided.

Images

Main Workflow

Manually insert the aluminum tube into the tube holder mold, and the tube holder mold rotates with the turntable, stopping at different workstations.

Firstly, come to the aluminum tube calibration station. The bottom of the tube holder mold will lift the aluminum tube and rotate it. The colored photoelectric detector will detect the color code at the tail of the aluminum tube. Once detected, the rotation will stop, the tube holder mold will descend to its original position, and the turntable will start to move to the next filling station.

The material that needs to be filled will be put into the hopper in advance. Through the piston type quantitative filling valve directly connected to the hopper, it will accurately and automatically inject the aluminum tube that intermittently stays on the filling station, The rotary table continues to rotate until it reaches the sealing and folding station for folding.

The rotary table continues to rotate until it reaches the folding station again. This is the final folding and sealing work, and then the rotary table rotates to the final station to push the aluminum tube away from the mold and slide it out of the machine through the slide.

Application

The aluminum tube filling sealing machine can be widely used in food, cosmetics, pharmaceutical and chemical industry, applicable for production of paste, adhesives, AB glue, epoxy glue, skin cream, hair dye, shoe polish, toothpaste, RTV silicone etc.

| Parts | Brand |

| Machine Body Material | Stainless steel SUS 304 |

| PLC | Panasonic(Japan) |

| Switch & Botton | Schneider(France) |

| Motor | Qipeng(China) |

| Variable-frequency Drive | Xinjie(China) |

| Cam Graduator | Yuntong(China) |

| Color Sensor | Panasonic(Japan) |

| Stepping | East(Japan) |