This article will be from the following standards to the filling machine classification:

1. Degree of Filling Automation

Manual filling machines can come in many different designs, but they all involve the operator manually filling the container with a specific volume of product. Some manual filling machines are very simple in design, such as a bottle filler with a valve and a lever to dispense the product. Others may be more complex, such as a piston-based manual filler, which uses a piston to dispense the product.

Manual filling machines are typically less expensive than automatic or semi-automatic filling machines, and they are suitable for low-volume production. They are also well-suited for filling small containers, and for filling products that are sensitive to heat or shear. However, manual filling can be time-consuming and labor-intensive, and it can also be less accurate than automated filling methods.

Manual filling machines are used for products such as food and beverage, pharmaceutical, cosmetics, chemicals, and many other types of liquid, paste, and powder products.

Semi-automatic filling machines can come in many different designs and configurations, depending on the type of product being filled, the type of container, and the filling method. They can be used for filling liquids, pastes, creams, and powders, and can be designed to handle a wide range of container sizes and shapes.

Semi-automatic filling machines are typically less expensive than fully automatic filling machines, and they are suitable for low- to medium-volume production. They offer more flexibility and control over the filling process than automatic machines, and they can be adjusted for different types of containers and products. However, they still require an operator to load and unload containers and to monitor the filling process, which can be less efficient than fully automatic machines.

Semi-automatic filling machines are widely used in many industries such as food and beverage, cosmetics, pharmaceutical, chemical, and many other types of liquid, paste, and powder products.

Semi Automatic Filling Machine

Automatic filling machines can come in many different designs and configurations, depending on the type of product being filled, the type of container, and the filling method. They can be used for filling liquids, pastes, creams, and powders, and can be designed to handle a wide range of container sizes and shapes.

Automatic filling machines are typically more expensive than manual or semi-automatic filling machines, but they offer higher production speeds and greater accuracy. They can be integrated with other automated equipment, such as capping machines and labeling machines, to create a fully automated production line. They are widely used in many industries such as food and beverage, cosmetics, pharmaceutical, chemical, and many other types of liquid, paste, and powder products.

2. Filling Product Type

Liquid/paste filling machines can come in many different designs, depending on the type of product being filled, the type of container, and the filling method.

Liquid/paste filling machines are widely used in many industries such as food and beverage, cosmetics, pharmaceutical, chemical, and many other types of liquid, paste products.

Liquid Filling Machine

Powder filling machines can come in many different designs, depending on the type of product being filled, the type of container, and the filling method.

Powder filling machines are widely used in many industries such as food and beverage, cosmetics, pharmaceutical, chemical, and many other types of powder products.

Semi Automatic Powder Filling Machine

Automatic Powder Bottle Filling Machine

Solid filling machines are widely used in many industries such as pharmaceutical, food, and confectionery. It is important to note that some solid products are sensitive to pressure, vibration, or heat, and therefore may require specialized filling equipment or modified filling methods to ensure accurate and consistent filling.

Aerosol filling machines are widely used in many industries such as personal care, household, automotive, and industrial. It is important to note that some aerosol products are sensitive to pressure, temperature, and humidity, and therefore may require specialized filling equipment or modified filling methods to ensure accurate and consistent filling.

3. Filling Measurement Method

Types of Liquid Filling Machines

The overflow filling machine is the most common liquid level filling machine.

An overflow filling machine is a type of liquid filling machine that uses a specific overflow level to fill containers with liquid. The machine fills the container with liquid until it reaches the overflow level, and then any excess liquid is drained back into the supply tank. This method is often used for products that have a consistent fill volume requirement and is ideal for products that have a high foaming tendency.

This method ensures that each container is filled to the same level, regardless of variations in container size or shape and it is a very precise method that delivers consistent fill volume with minimal foaming. This type of filling is used for products like beer, soda, and other carbonated beverages that have high foaming tendencies.

Automatic Overflow Filling Machine

Common volumetric liquid filling machines are as follows:

Gravity filler: This type of volumetric filling machine uses the force of gravity to dispense a specific volume of liquid into the container. The liquid is dispensed into the container by a filling head and the volume of liquid is controlled by adjusting the height of the filling head. This method is often used for low-viscosity liquids and can be adjusted to accommodate different viscosities.

Automatic Gravity Filling Machine

VK-PF Automatic Piston Filling Machine

Follow Tracking Rotary Lobe Pump Filling Machine

Automatic Rotary Lobe Pump Filling Machine

Automatic Net Weight Filling Machine

Types of Powder Filling Machines

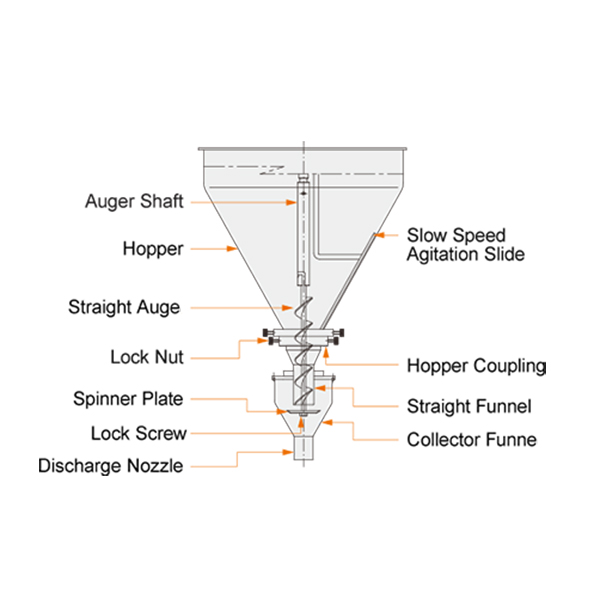

How Does An Auger Filler Work?

The machine typically consists of a hopper, a filling head, a container holding area, a control system, and weigh scale. The hopper holds the powder and feeds it to the filling head. The filling head is positioned above the container and dispenses the powder into the container. The container holding area holds the container in place while it is being filled. The control system manages the filling process, including controlling the flow of powder, the speed of the filling process, and the timing of the filling cycle. The weigh scale is used to measure the weight of powder being dispensed and to adjust the settings on the machine to achieve the desired weight.

This type of filling machine is suitable for powders with low to moderate flowability and can dispense powders with consistent weight, with minimal dusting. This machine can be adjusted to accommodate different densities and can be integrated with other equipment such as capping machines, labelers, and conveyors for automation in a production line.

Types of Solid/Granule Filling Machines

4. Filling Container Type

The bottle filling machine can be used to fill different types of bottles, such as round, square, or oval-shaped bottles, and can be adjusted to accommodate different bottle sizes and shapes. Bottle filling machines can be integrated with other equipment such as labelers, and conveyors for automation in a production line. They are widely used in industries such as food, beverage, chemical, pharmaceutical, and personal care products.

The jar filling machine can be used to fill different types of jars, such as round, square, or oval-shaped jars, and can be adjusted to accommodate different jar sizes and shapes. Jar filling machines can be integrated with other equipment such as labelers, and conveyors for automation in a production line. They are widely used in industries such as food, chemical, pharmaceutical, and personal care products.

Jar Filling Machine

Tube Filling And Sealing Machine

Automatic Drum Filling Machine

5. Filling Direction

Linear Filling Machine: The Ultimate Guide

This type of machine is generally more efficient and faster than linear filling machines, as the rotation of the carousel allows for multiple containers to be filled at the same time. Additionally, many rotary filling machines are also equipped with additional functions such as capping and labeling to make the whole packaging process more efficient.

In conclusion, there are various types of filling machines available on the market, each with its own unique features and capabilities. The right choice will depend on the specific product, production process and the requirement of the industry. It is essential to consult with a filling machine expert or supplier to ensure the best choice of filling machine is made for your specific application.

VKPAK's Filling Machine

VKPAK is a company that specializes in the manufacturing and sales of filling equipment and machinery. They offer a wide range of filling machines, including overflow filling machine, volumetric filling machine, net weight filling machine; These machines can be used to fill a variety of containers, such as bottles, jars, tubes and barrels, with different types of products, such as liquids, pastes, and powders. We can also be customized to meet specific customer requirements.

If you are looking for a filling machine manufacturer, please contact us, our professional engineers will recommend the most suitable filling equipment, capping, labeling equipment, etc.

Related Articles

Linear Filling Machine: The Ultimate Guide Welcome to The Ultimate Guide to Linear Filling Machines! A linear filling machine is a type of […]

Linear Filling Machine: The Ultimate Guide Welcome to The Ultimate Guide to Linear Filling Machines! A linear filling machine is a type of […] Square Bottle Labeling Machine Square bottle is a common bottle in daily life, including glass square bottle, plastic square […]

Square Bottle Labeling Machine Square bottle is a common bottle in daily life, including glass square bottle, plastic square […] Mustard Oil Filling Machine: The Selection Guide Brief introduction of mustard oilMustard oil filling machine selection

Whether mustard oil is […]

Mustard Oil Filling Machine: The Selection Guide Brief introduction of mustard oilMustard oil filling machine selection

Whether mustard oil is […] Common Liquid Viscosity Chart Our viscosity chart can help you get an idea of how thick your product is. While these are only […]

Common Liquid Viscosity Chart Our viscosity chart can help you get an idea of how thick your product is. While these are only […] PET Bottle Filling Machine PET bottles are a common container in the packaging industry and can be found in almost every […]

PET Bottle Filling Machine PET bottles are a common container in the packaging industry and can be found in almost every […] Tincture Bottle Labeling Machine What is Tincture?

Tinctures are concentrated herbal extracts made by soaking the bark, berries, […]

Tincture Bottle Labeling Machine What is Tincture?

Tinctures are concentrated herbal extracts made by soaking the bark, berries, […] 2 Nozzle Liquid Filling Machine As the name implies, a two-nozzle filling machine is a filling machine with two filling heads. […]

2 Nozzle Liquid Filling Machine As the name implies, a two-nozzle filling machine is a filling machine with two filling heads. […] Inline Capping Machine A bottle cap machine is a machine that tightens or secures a container’s cap. Every company that […]

Inline Capping Machine A bottle cap machine is a machine that tightens or secures a container’s cap. Every company that […]