As the name implies, a two-nozzle filling machine is a filling machine with two filling heads. There are many types of 2-nozzle filling machines according to different filling principles, such as: 2-head piston filler, 2-head pump filler, 2-nozzle net weight filling machine, etc. In addition, there are semi-automatic and full-automatic according to the degree of automation. Here are some examples of our 2-nozzle liquid filling machines.

Economical 2 Nozzle Filling Machine For Liquid Soap

The VKPAK automatic linear piston filler is manufactured with a 304 stainless steel frame and is capable of supporting 2 to 4 fill nozzles PLC Controls, touch screen, food grade contact parts, stainless steel and anodized aluminum construction, plus many more features come standard.

IT adds efficiency to any production line used in the cosmetic, food industry, specialty chemical, pharmaceutical, and personal care industries. Additional options are available for sanitary, hazardous, flammable and corrosive environments.

Automatic 2 Nozzle Juice Filling Machine

1. Equipped with horizontal mixing hopper, double screw forward and reverse mixing, the mixing time can be set freely, which can ensure the material uniformity and no oil sauce separation in the filling process to ensure the filling accuracy of each bottle.

2. The design of the equipment greatly shortens the filling distance from the hopper to the filling head, and overcomes the shortcomings of large filling error in the filling process.

2 Head Filling and Capping Machine For Cosmetic

This machine is applicable to the Cosmetics industry in the 2-500 ml bottle of liquid filling and sealing packing process, high precision piston pump (or peristaltic pump) filling, measuring accurate, adjustable, convenient maintenance, easy operation, no bottle no filling, no bottle no plug, not plug cover function.

2 Nozzle Follow Tracking Rotary Lobe Pump Filling Machine For Sauce

This machine adopts optical fibers to track bottle for high speed and high efficiency filling, and there is no break in the production process.

- It is suitable for daily chemical liquid paste filling such as shampoo, sauce, shower gel, lotion, liquid soap and detergent.

- Fully automatic operation, bottle entry, positioning, filling and bottle exit are automatically controlled by PLC, and the whole process meets GMP standards

- According to the characteristics of different products, we can provide piston, rotor pump, flowmeter, solenoid valve and other measurement methods.

- For different types bottle of different heights and capacities, especially special-shaped bottles, it only takes 3-5min to complete the commissioning.

- It solves the problems of time-consuming and laborious due to a wide variety, small number of single products and frequent machine adjustment. At the same time, it is suitable for mass production

Main features

- High speed—40-50 bottles/min with only 2 filling nozzles

- Wide Application— fast switching for various bottles and products

- Easy but High Clean—rotor pump control, CIP cleaning optional

- Touch screen operation interface

- Support up and down movement type filling to effectively prevent foam generation

- The filling accuracy can reach ±1% (depending on the product, the filling accuracy is different)

- The filling cylinder is treated and ground by hard chromium, with a unique filling valve design, no leakage

- No bottle no filling function

- Design different positioning devices according to the actual situation of the bottle

- The equipment is easy to clean, and it can also be cleaned online or sterilized by high temperature

- The equipment and material contact are all made of 304# stainless steel

- Less area occupancy

Semi Automatic 2 Nozzle Explosion Proof Net Weight Filling Machine

This explosion-proof two-head epoxy filling machine adopts the filling method in the barrel mouth, which is suitable for the filling of curing agent-type non-foaming liquid materials. The uniquely designed filling head device is easy to operate, and the filling is fast and precise; During operation, the operator simply aligns the barrel mouth directly under the filling head, presses the [Start] button on the handle, and the system will automatically tare the empty barrel and automatically charge nitrogen for N seconds. Then open the filling valve to accurately fill at two speeds; when the filling is over, the filling head is automatically closed, and the barrel is manually pushed out of the weighing table and capping is completed.

Semi Automatic 2 Nozzle Piston Filling Machine

Double heads filling machine is a semi-automatic filling equipment. The machine can be foot-operated or photoelectric switch control filling and can be automatically filled online; suitable for a variety of fluidity materials, widely used in pharmaceutical, cosmetic, food, pesticides and special industries, is the ideal low viscosity fluid filling equipment.

Applications:

Suitable for perfume, toilet water, eye drops, nail polish, sesame oil, wine, liquor, battery liquid, detergent and other low-dose liquid filling, is ideal for your wiring or stand-alone use. The machine is easy to maintain, does not require special maintenance tools, has a high filling accuracy, there will be no leakage phenomenon, according to your special requirements of the number of custom filling mouth.

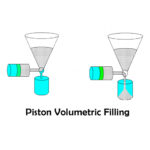

Filling principle:

The machine is a semi-automatic piston filling machine, which is driven by a cylinder to extract and eject material. The material flow is controlled by a three-way rotary valve. The stroke of the cylinder can be controlled by the reed switch. The filling volume can be adjusted, You can adjust the intake air cylinder to achieve rapid or slow filling.

Product advantage:

1, This machine is made of 304 stainless steel, meeting the CE requirements;

2, Filling capacity and filling speed can be adjusted;

3, Filling system quick release design, easy to washable after used;

4, Pneumatic components are adopted top-brand pneumatic components;

5, Using PTFE seals and silicone seals (endure high temperature, acid and alkali resistant, and non-toxic environmental protection);

6, Filling mouth anti-drawing, anti-drip design;

7, Quick filling speed, high filling accuracy;