Introduction

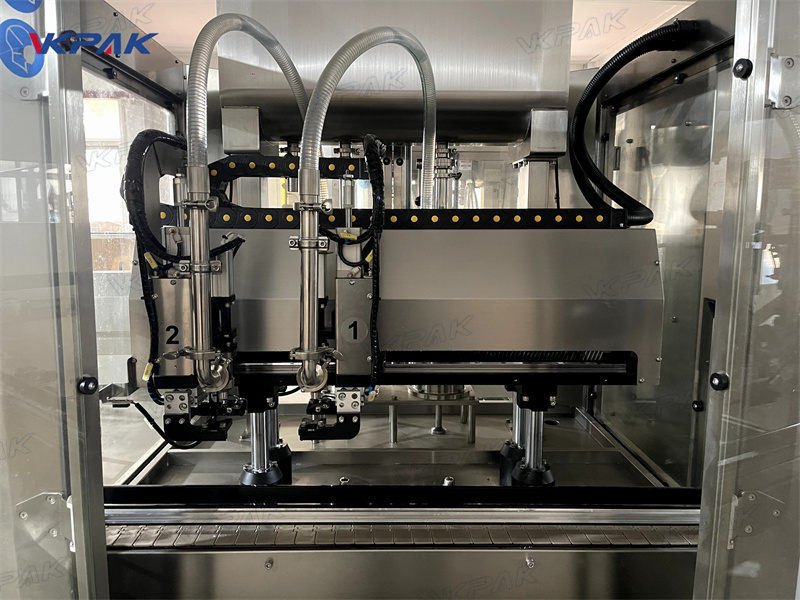

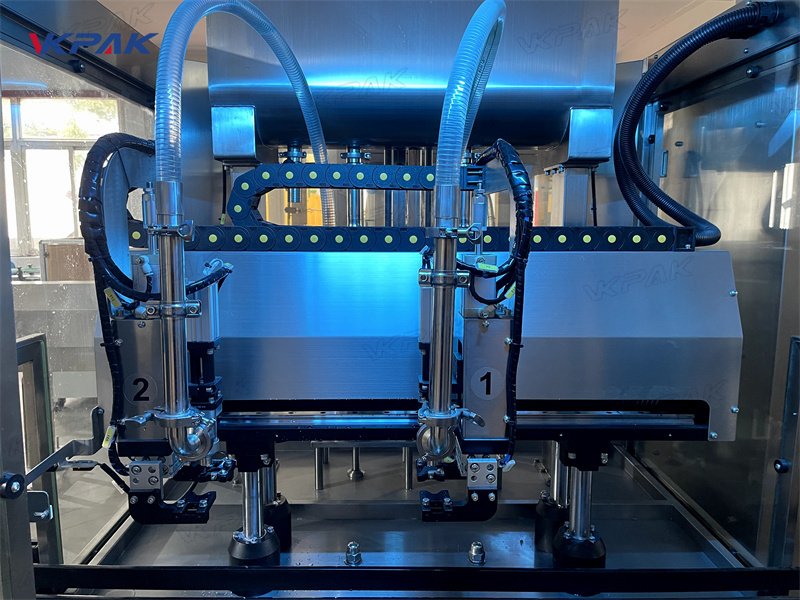

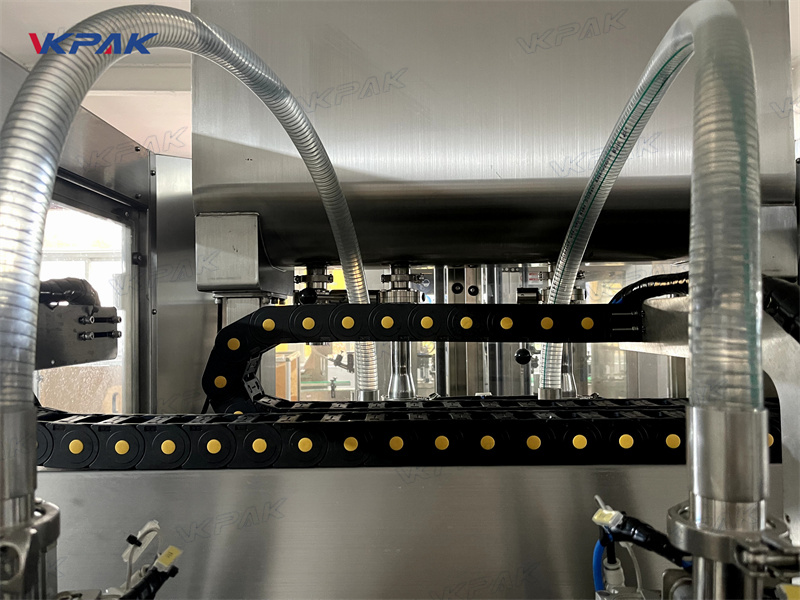

The VK-PF-T is equipped with servo motor and you just need to enter the certain number to adjust filling range. Compared with other filling machine, this tracking type filling machine can control filling nozzle follow moving bottles during filling work. It reduce production error and improve filling accuractely. It is designed for filling paste like curry paste, tomato sauce, pepper sauce, each nozzle can be controlled separately.

This series of filling machine is equipped with 2,4,6,8 filling nozzles, the metering method adopts piston filling, the output capacity of 2000-6000 bottles per hour (related to the size of the bottle and the diameter of the bottle mouth).

Model: VK-PF-T

View Video Operation Video1. Filling is controlled by servo piston pump, you can set your filling volume directly.

2. This tracking type filling machine can control filling nozzle follow the bottle during the filling process.

3. Suitable for filling paste like shampoo, lotion, laundry detergent, etc. Each nozzles can be controlled separately.

Parameter

| Model | VK-PF-T2 | VK-PF-T4 | VK-PF-T6 |

| Nozzle Number | 2 | 4 | 6 |

| Filling volume | 100-5000(Can be customized) | ||

| Production capacity | 20-40 BPM | 30-60 BPM | 40-80 BPM |

| Quantitative error | ≤±1% | ||

| Voltage | 380V/220V/110V | ||

| Air Pressure | 0.6-0.8MPA | ||

| Air consumption | 6-7m³/min | ||

| Machine Weight | 520kg | 900kg | 1200Kg |

Working Video

2. Applicable to a wide range of bottle types: as long as you can stand on the line does not fall, the mouth of the bottle vertically upward of a variety of shaped bottles are also applicable, without special adjustment, the bottle will be placed on the conveyor can be arbitrary, greatly reducing the labor intensity of workers;

3. Applicable to a wide range of products: suitable for cosmetics, food industry cream oil products: such as: shampoo, laundry detergent, hand sanitizer, body lotion, hair conditioner, oxygenated milk, essential oils, food/industrial oils and so on;

4. High efficiency: filling speed, good stability, each filling capacity cylinder using servo motors to control individually, high filling accuracy;

5. Filling accuracy can reach ±1%;

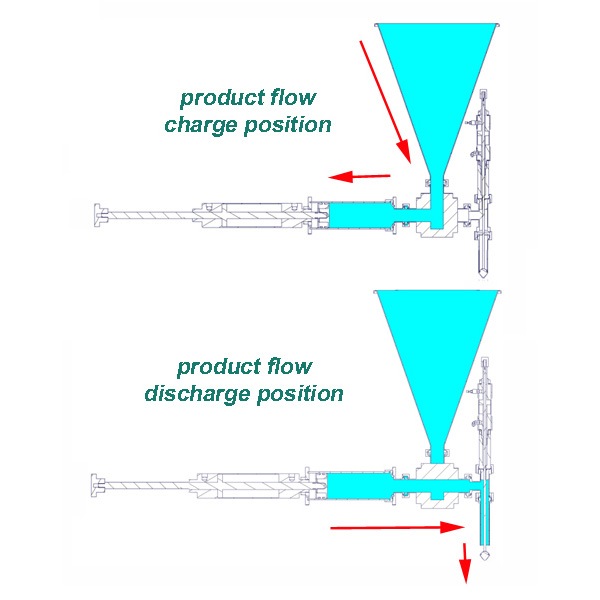

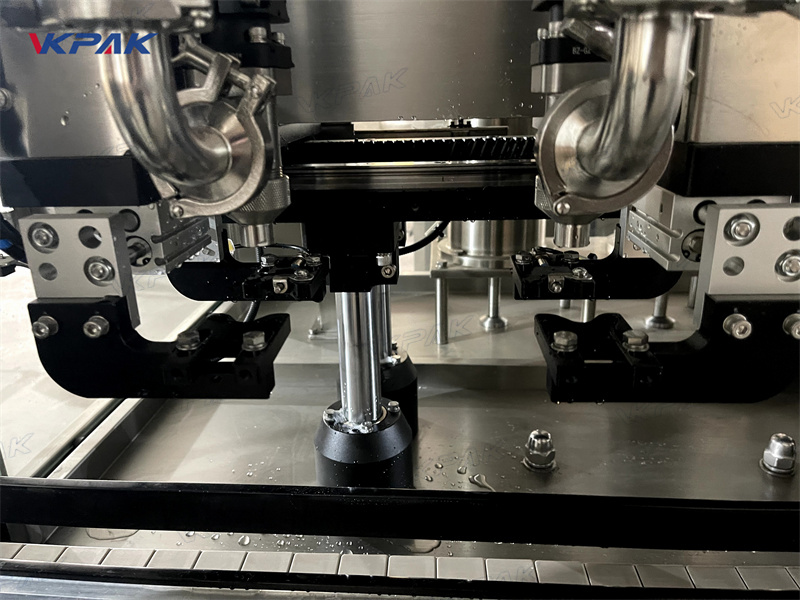

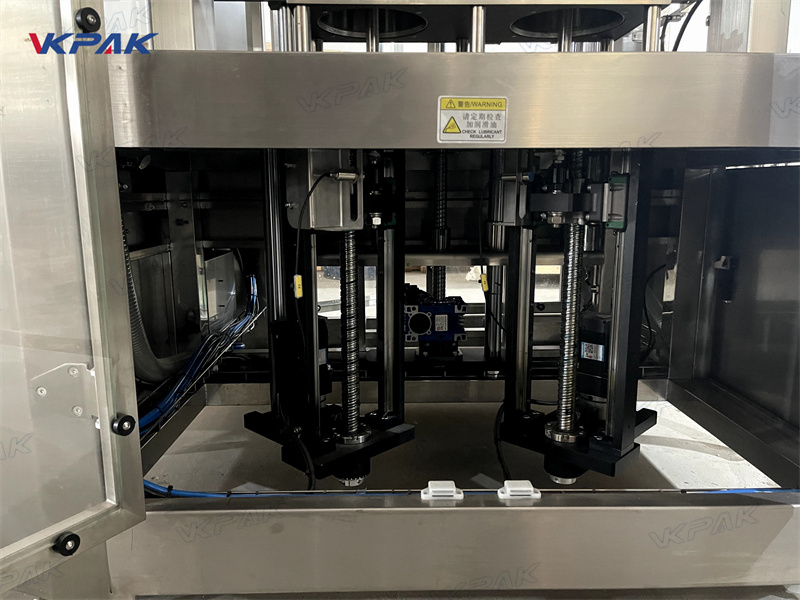

6. The metering cylinder is processed by hard chrome and internal grinding, with unique rotary valve design, accurate metering, no dripping;

7. Sensor monitoring, no bottle not canning, accumulation of bottles automatic shutdown function;

8. Strong compatibility, large and small bottle type universal, simple adjustment, faster turnaround time;

9. The material contact parts of the equipment are using a live connection mechanism, without the need for any tools to disassemble, cleaning is more convenient;

10. The whole machine is made of 304# stainless steel, aluminum-magnesium alloy parts are anodized, with strong abrasion resistance, good insulation, corrosion resistance and other advantages;

11. The machine can store 8 groups of bottle data, replace the bottle just choose which group of parameters, the machine can be automatically adjusted according to the data; to do a key adjustment, intelligent and efficient;

| Descriptions | BRAND |

| Servo Motor | Inovance |

| Servo Drivers | Inovance |

| PLC | Inovance |

| Touch Screen | Inovance |

| Photosensor | Sick |

| Air cylinder | Airtac |

| Electromagnetic Valve | Airtac |

| Bottle Sensor | Sick |

| Frequency Transformer | Inovance |

| Low Voltage Apparatus | Schneider |

| Lead Screw | TBI |

| Straight Slide Track | Frey |

Different from other filling machines, the filling heads of this machine will automatically move with the bottles during filling, rather than stopping to fill. Greatly improve efficiency. With anti-dripping function, it will fill liquid accurately.

lt is designed for detecting bottles, ensuring they can be filled accurately, realizing automated production. The position and sensitivity of electric eye can be adjusted according to production need. Easy to operate.

With chain conveyor belt, it can transport large volume products steadily and smoothly. Improve work efficiency. The width of feed inlet can be adjusted as needed, making it suitable for products of different sizes.

Made of high quality materials, the piston cylinder will measure precisely, which helps to realize quantitative filling. The food grade material makes it possible to fill food materials, ensuring production quality.