Introduction

This VK-PF-M servo filling machine can set filling volume by entering certain number, it is also equipped with mobile following filling nozzle, which will follow bottles during transporting and finish the filling work in this period. It is widely used in food, daily chemical and cosmetics industries.

Filling Head Optional: 6/8/10/12 Heads

Filling Volume: 50-1000Ml

Model: VK-PF-M

View Video1. Servo Drive System

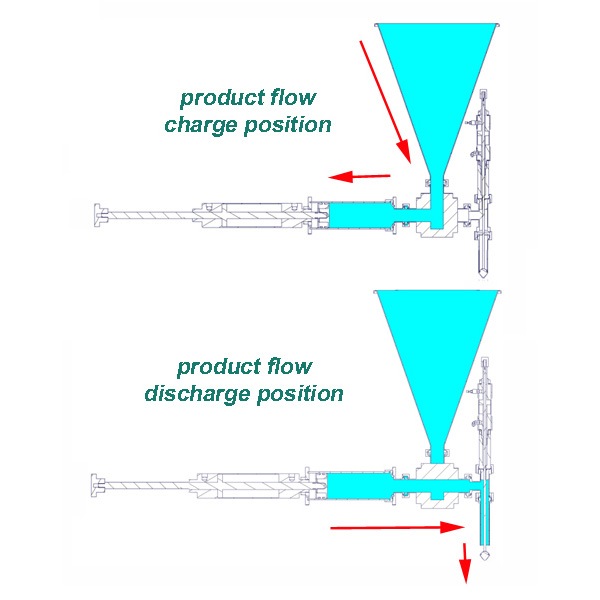

The volumetric filling system utilizes the delicate servo drive system to control the main filling structure, achieving high stability and precise positioning. With the vertical movement of the filling piston provides long term energy saving and also effectively reduces machine load rate.

2. High Accuracy

The delicate servo system controls the filling amount through precise piston strokes, providing high filling accuracy. The piston is intelligently designed with an adjusting mechanism to enable users to obtain ultimate higher accuracy.

3. High Adaptability

The automatic servo filling machine can be used in food, pharmaceuticals, chemicals, cosmetics, and other industries.

Parameter

| Model | VK-PF-M8 | VK-PF-M10 | VK-PF-M12 |

| Nozzle Number | 8 | 10 | 12 |

| Filling volume | 100-1000(Can be customized) | ||

| Production capacity | 50-70 BPM | 70-80 BPM | 80-100 BPM |

| Quantitative error | ≤±1% | ||

| Voltage | 380V/220V/110V | ||

| Air Pressure | 0.6-0.8MPA | ||

| Air consumption | 6-7m³/min | ||

| Machine Weight | 520kg | 900kg | 1200Kg |

Working Video

2. Adjustable filling speed.

3. Accurate to ≤±1%.

4. Integrated digital control with PLC and high-tech touch screen controls for easy operation.

5. GMP standard stainless steel.

6. Bottom-up filling for option.

7. Bottle neck location.

8. No bottle-no fill system.

9. Filling zone protected by stainless steel frame.

10. Volume is easily adjusted through touch screen. Filling pistons are controlled by servo system.

11. Individual piston adjustment.

| Descriptions | BRAND |

| Servo Motor | Inovance |

| Servo Drivers | Inovance |

| PLC | Inovance |

| Touch Screen | Inovance |

| Auxiliary Relay | Siemens |

| Air Cylinder | Airtac |

| Electromagnetic Valve | Airtac |

| Fibre Optic Sensor | Keane |

| Bottle Sensor | Keane |

| Frequency Transformer | Inovance |

| Circuit Breaker | Delixi |

| Lead Screw | TBI |

| Contactor | Delixi |

Multiple filling nozzles can be customized as need. The following filling nozzles will follow bottles during transporting and finish the filling work in this period. This can improves working speed greatly.

Equipped with the electric eye, it will send out signal to the signal when detects passing by bottles, it improves filling accuracy.

The bottle separating component can help to adjust the distance between bottles and bottles, ensure the filling nozzle can be inserted into bottles correctly and finish the filling work, prevent liquid spraying out.