The principle of piston filling is actually very simple. At the beginning the valve is linked to the hopper and the piston cylinder, then the piston extracts the material from the hopper into the piston cylinder, then the valve turns to the filling nozzle (the valve is linked to the piston cylinder and the filling nozzle), and finally the piston pushes the material in the cylinder to flow from the filling nozzle to the packaging container. This process creates a highly accurate volumetric fill as the interior volume of the cylinder will never change, meaning the volume of product released to the bottles will never change.

Piston filling systems are suitable for liquids ranging from thin viscosities to thick. They are also able to process semi-solids and liquids with particulates. They pump product into containers in very precise amounts, delivered from a bulk tank that can also be configured with a buffer tank utilizing a level-sensing float, a manifold with directdraw, or recirculation methods. VKPAK offers different models of piston fillers suitable for high-volume industrial needs, startups seeking more economical models, and automatic enterprises. We can also customize your equipment to make filling even more efficient, such as adding a heated hopper to a piston filler to warm up thicker liquids, making them flow more easily.

Piston Filler Working Principle

Used primarily for thick viscous liquids and/or products with particulates and limited changeovers. This type of piston filler is best suited for viscous products that are paste, semi paste, or chunky with large particulates. These piston fillers are built to meet food grade standards and can also handle various chemical applications.

Examples

Heavy sauces, salsas, salad dressings, cosmetic creams, heavy shampoo, gels, and conditioners, paste cleaners and waxes, adhesives, heavy oils and lubricants.

Advantages

This lower cost conventional technology is easy to understand for most users. Fast fill rates are achievable with fairly thick products.

The steps below describe how piston fillers work.

- The valve, which is located between the nozzle and the hopper, opens to release the liquid product from the hopper into the cylinder.

- The piston helps fill the cylinder by pulling the product from the hopper until the empty cylinder is filled.

- Once the piston has pulled at a pre-set length, the valve rotates allowing the product to flow to the nozzle.

- The piston pushes back into the cylinder to help the product move through the nozzle.

- The nozzle dispenses the product into the waiting containers.

5 Main Components of a Piston Filler

The Hopper – Holds bulk quantities of the product to be filled into the containers.

The Piston – Pulls product from the hopper to the piston cylinder.

The Piston Cylinder – Has a constant interior volume for consistent fill levels.

The Valve – Opens and closes to allow and stop product flow through the nozzle/s.

The Nozzles – Dispenses product from the piston cylinder to the waiting containers.

6 Details About Piston Filling Machine

- The piston’s length of stroke and the cylinder’s inside diameter will determine the fill volume of the machine. Larger cylinders can accommodate more product.

- You can adjust the fill volume on the machine by setting the piston’s stroke length usually through a handwheel.

- You can adjust the speed of the piston’s movement.

- The size of the hopper can vary depending on the size of your containers. For instance, automatic piston fillers will likely pull products from a bulk source such as a tank.

- The machine’s piston and cylinder are available in various sizes for accommodating different project needs.

- Different nozzles are also available depending on the type of product you are handling.

Types of piston filling machines

Check Valve Piston Filling Machines

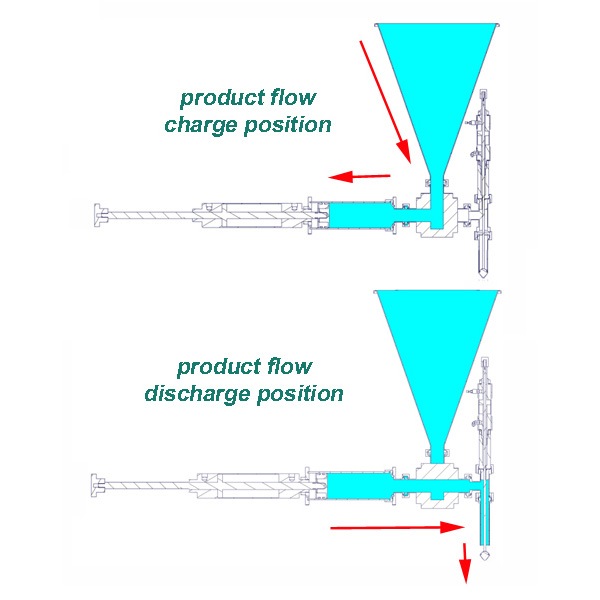

A check valve piston filler works on a check valve principle that opens the infeed valve on the draw stroke then forces the draw side check valve closed while opening the discharge valve on the dispense stroke as can be seen clearly by the animation to the right.

The big advantage of a check valve filling system is it can self prime and draw product directly from a drum or other container without need for pumping or otherwise transferring product to another vessle. Simply drop the hose into the drum, adjust the fill volume and start filling product with excellent accuracy of +/- one half percent.

Check valve piston fillers work well with most any free flowing liquid (meaning it pours easily), but does not work well on thicker products or products with particulates in them as they can foul the valves.

Rotary valve piston filling machines

Rotary valve piston filling machines can do all of the “hard” jobs like filling pastes and products with particulates such as cottage cheese, potato salads, peanut butter, salsas and many other chunky products.

The concept is actually rather simple in that the hopper flood feeds the rotary valve which connects between the hopper and cylinder on the draw stroke and then flips ninty degrees between the cylinder and discharge tube on the dispense stroke, as can be seen in the animation on the right. Because the rotary valve can be hollowed out, large particles of up to one half inch (sometimes larger) can pass through without damage.

Rotary valve piston filling systems are available as benchtop, automatic inline, and rotary high speed systems and can be sized for your range of filling needs up to a 10:1 ratio and maintain its amazing +/- one half percent accuracy.

Advantages of a Piston Filler

1 They can handle all product viscosities.

While piston fillers are ideal for handling viscous products and those with large particulates, you can also use them for filling thin products.

2 They are available in various nozzle types.

The customizability of the nozzles of piston fillers adds to their versatility. Different nozzles can be designed to meet your product’s specific needs.

3 They can handle different container materials and sizes.

Since the cylinder and piston of these machines come in various sizes, you can use piston filling machines for both small and large containers. But, do note that if you are handling tiny to large containers, you may need multiple piston sizes.

4 They can handle particulates in the products.

Sauces and jams can have large chunks of vegetables or fruits which can clog the nozzles of piston fillers. But, with the teamwork between the cylinder and the piston, this issue can be dealt with without any problem.

5 They produce accurate volumetric fills.

The constant interior volume of the cylinder in every fill cycle allows piston fillers to produce consistent volumetric fills with each stroke of the piston.

Customize Your Piston Filling Machine

The hopper sizes can vary from project to project based on the size of the containers or fills. Not all piston filling machines, and in particular, the automatic piston fillers, will use a hopper from which to pull product. Automatic lines will likely include a tank or pull from a bulk source. The cylinder and piston combination are also available in different sizes to accommodate different projects. The speed with which the piston moves can be adjusted, different piston sizes can be used to meet volume requirements and even multi-piston, automatic filling machines can be designed for use with inline packaging systems. VKPAK piston fillers allow the operator to adjust the length of the piston stroke, which in turn adjusts the volume of product that is pulled in to the cylider with each fill cycle. This way a single piston size can handle a range of container sizes. While multiple strokes of the piston can also be used for larger fills, at some point the efficiency of using multiple strokes will become low enough that simply changing out the piston for large containers will be the better solution.

The nozzle used on any piston filler will be chosen to meet the needs of the particular project at hand. For instance, a product with large chunks of fruit or vegetables will not work well if a narrow nozzle is used to move product in to the bottles. On the other hand, a very large nozzle will be cumbersome with a small mouthed bottle. There is virtually no limit to the type of nozzles that can be used, including custom manufactured nozzles where special projects are concerned.

Though a simple concept, the piston filler can be an ideal solution for many projects and for liquids thick and thin. Though these machines are known for handling viscous products, in the right circumstances they will handle free-flowing liquids as well. For assistance finding the best type of filling machine for your own packaging project, contact VKPAK today.