The packaging industry has come a long way over the years, and one of the most important innovations in this field has been the development of glass bottle filling machines. These machines are designed to automate the process of filling glass bottles with a wide range of products, from liquids and sauces to pastes and powders. Their importance lies in their ability to increase production output, improve product consistency, and reduce labor costs.

In this guide, we will take an in-depth look at glass bottle filling machines, including the different types available, how to choose the right machine for your application, and the key components that make these machines work. We will also cover the operational aspects of glass bottle filling machines, including how to set them up, how to maintain them, and how to troubleshoot common issues. Whether you're a packaging industry professional or simply curious about this fascinating topic, this guide is designed to provide you with all the information you need to understand the world of glass bottle filling machines.

Glass Bottling Machine Line From VKPAK

Monoblock 20ml Glass Bottle Filling Machine For Pharmaceutical

Overflow Glass Bottling Machine For Liquor

Whiskey Glass Bottle Filling Line

Piston Glass Bottle Filling Machine

Oral Liquid Filling And Sealing Machine

Piston Glass Bottle Filling Machine For Sauce

What is Glass Bottle Filling Machine?

Glass bottle filling machines are mechanical devices that are used to fill glass bottles with various types of products. These machines are typically used in the food and beverage, chemical, and pharmaceutical industries, among others. There are many different types of glass bottle filling machines, each designed to suit a specific product or application. The most common types include gravity fillers, pressure fillers, vacuum fillers, piston fillers, overflow fillers, benchtop fillers, rotary fillers, inline fillers, and monoblock fillers.

The importance of glass bottle filling machines in the packaging industry is that they are able to automate the filling process, which can lead to a number of benefits. They can increase production output, improve product consistency, and reduce labor costs. Automating the filling process also minimizes the risk of contamination and human error, which can be a major concern in the food and beverage industry, for example. Additionally, these machines are able to handle a wide range of products and bottle sizes, which makes them ideal for packaging a variety of items.

In addition, glass bottles are considered a suitable container for many products because they provide an excellent barrier against light and air which helps the product to retain its quality and extends shelf life. And filling those bottles with a machine increase the speed, efficiency and accuracy of filling.

Overall, glass bottle filling machines play a vital role in the packaging industry, providing a reliable and efficient way to fill glass bottles with a wide range of products.

Types of Glass Bottle Filling Machines

There are many different types of glass bottle filling machines available, each with their own unique features and capabilities. Here is a brief overview of some of the most common types:

♦ Gravity filler:

This type of machine uses gravity to fill bottles with a product. It relies on the weight of the product to move it from a hopper into the bottle. Gravity fillers are typically used for free-flowing products such as water, juice, and wine.

♦ Pressure filler:

A pressure filler uses pressure to move the product into the bottle. It relies on a pump to create a pressure differential between the product and the bottle, causing the product to flow into the bottle. These fillers are used for products that are more viscous, like sauces, syrups and oil.

♦ Vacuum filler:

This type of machine uses a vacuum to fill bottles. It creates a vacuum inside the bottle, drawing the product into the bottle. Vacuum fillers are typically used for products that are sensitive to oxygen, such as wine and beer.

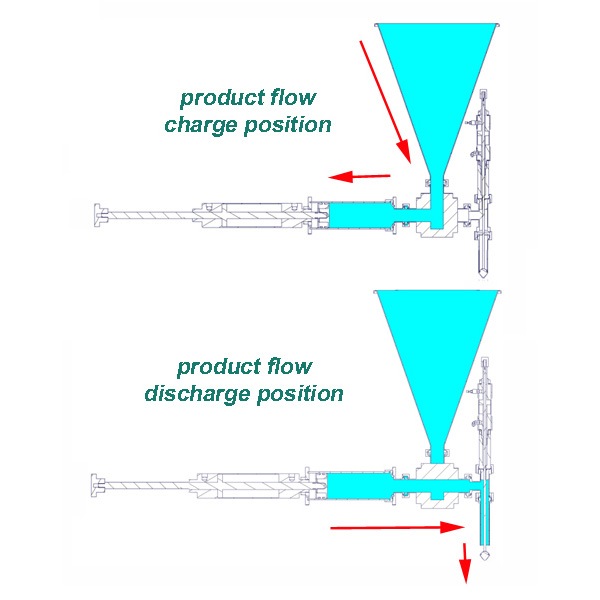

♦ Piston filler:

A piston filler uses a piston to move the product into the bottle. It relies on a reciprocating motion to fill the bottle, which makes it well-suited for products that are more viscous and not free-flowing.

♦ Overflow filler:

An overflow filler uses a fill level control to fill the bottle with a product. The product is added to the bottle until it reaches a certain level, and then the excess is drained off. This type of filler is well-suited for products that foam or that require a very precise fill level.

♦ Benchtop filler:

A benchtop filler is a smaller, manually operated machine that sits on a bench or table. These fillers are typically used for small-scale production or for filling test bottles.

♦ Rotary filler:

This type of machine uses a rotating carousel to fill bottles. The bottles are loaded onto the carousel, and as it rotates, each bottle is filled in turn. Rotary fillers are typically used for high-speed production lines and for filling a large number of bottles in a short period of time.

♦ Inline filler:

An inline filler is a machine that is integrated into a production line. These fillers are typically used for products that require a high degree of accuracy and consistency, like pharmaceuticals.

♦ Monoblock filler:

A monoblock filler is a machine that combines the functions of filling, capping, and labeling into a single unit. These fillers are typically used for high-speed production lines and for products that require a high degree of accuracy and consistency.

It's worth noting that each one of these machines may have variations based on the specific design, however these are the common types of glass bottle filling machines available.

Detailed introduction of various glass bottle filling machines

Choosing the Right Glass Bottle Filling Machine

Factors to Consider When Selecting a Glass Bottling Machine

There are several factors to consider when selecting a glass bottle filling machine, including:

# Production Output:

The production output of the machine is an important factor to consider, as it will determine how many bottles can be filled in a given period of time. If you are planning a high-volume production line, then a rotary filler or an inline filler would be a good option, while a benchtop filler would be more suitable for small-scale production.

# Product Viscosity:

The viscosity of the product will also be a major consideration. For free-flowing products such as water or juice, a gravity filler would be a good option. For more viscous products such as sauces or syrups, a pressure filler or a piston filler would be more suitable.

# Bottle Size:

The size of the bottle is also an important factor to consider, as different filling machines are designed to handle different bottle sizes. Some machines are capable of handling a wide range of bottle sizes, while others are designed for a specific size of bottle.

# Product Characteristics :

Product characteristics such as pH, temperature, pressure and foaming can impact the design and performance of the machine. For instance, products that foam or that require a very precise fill level like low-density liquids, or high-temperature liquids, an overflow filler might be more suitable.

# Aseptic filling requirement:

If the product needs to be filled under aseptic condition to maintain its shelf life or quality, the filler machine should be designed for aseptic filling.

# Initial and running cost:

The purchase cost, maintenance and running cost should be considered when selecting a machine. Some machines are relatively expensive to purchase, but have low maintenance and running costs, while others may be less expensive initially, but have higher ongoing costs.

# Capacity and growth:

The current and future capacity and production rate should be taken into consideration. For example, A benchtop filler might be suitable for a small scale business with low production rate, but in case of an expansion in the future, investing in a rotary filler or an inline filler, with the capability of handling large volume of bottles would be more suitable.

Applicable Products for Different Machines

Different types of glass bottle filling machines are better suited for different applications, depending on factors such as the production output, the viscosity of the product, and the size of the bottle. Below is a general comparison of different types of machines and their suitability for different applications:

# Gravity filler:

Suitable for free-flowing products such as water, juice, and wine. Simple and reliable, with low maintenance. Good for small-scale production lines.

# Pressure filler:

Suitable for more viscous products such as sauces, syrups, and oil. Known for accuracy and precision, often used in high-volume production lines. However, they may require frequent maintenance and cleaning, and can be relatively expensive to purchase and operate.

# Vacuum filler:

Suitable for products that are sensitive to oxygen, such as wine and beer. Minimizes the amount of oxygen that enters the bottle during the filling process, resulting in a longer shelf life for the product. However, vacuum fillers can be relatively expensive to purchase and operate, and also have a higher maintenance cost than other types of fillers.

# Piston filler:

Suitable for more viscous products such as thicker liquids and semi-solid products like gels or pastes. Known for accuracy and precision, and can handle different types of containers. However, they tend to be more complex and require regular maintenance.

# Overflow filler:

Suitable for products that foam or that require a very precise fill level. Known for precision and accuracy, and relatively low maintenance.

# Benchtop filler:

Suitable for small-scale production or for filling test bottles. Simple and easy to use, relatively inexpensive, and easy to clean. However, since they are manually operated, the speed and accuracy of filling may vary depending on the operator's skill level.

# Rotary filler:

Suitable for high-speed production lines and for filling a large number of bottles in a short period of time. Known for high-speed and efficiency, and can handle a wide range of bottle sizes and shapes. However, these machines can be relatively expensive to purchase and operate, and they may also require frequent maintenance and cleaning.

# Inline filler:

Suitable for products that require a high degree of accuracy and consistency, like pharmaceuticals, food and beverages products. They are designed to work with other machines such as cappers, labelers and conveyors in a seamless and efficient manner. They are known for high-speed, accuracy and consistency of filling. However, they can be relatively expensive to purchase and operate.

# Monoblock filler:

Suitable for high-speed production lines and for products that require a high degree of accuracy and consistency. They combine the functions of filling, capping, and labeling into a single unit, known for efficiency, automation, and ease of use. They can handle large volumes of bottles at a time, but are relatively expensive to purchase and operate, and may require frequent maintenance and cleaning.

It's worth noting that these are generalities, and that many machines are designed to handle multiple types of products, containers, and production volume, it's important to consider the specific requirements of your application and to consult with the manufacturer or a professional to select the best machine for your needs.

Glass Bottle Filling Machine Components

Key Components of a Glass Bottle Filling Machine

Glass bottle filling machines are composed of several key components that work together to accurately and efficiently fill bottles with a product. Some of the main components of a glass bottle filling machine include:

◊ Filling nozzles:

These are the parts of the machine that dispense the product into the bottles. They can be designed in different ways, depending on the type of machine and the product being filled. For example, some machines use a single filling nozzle, while others use multiple nozzles for high-speed production.

◊ Valves:

Valves are used to control the flow of product from the hopper to the filling nozzle. They can be manual or automatic, depending on the type of machine. Automatic valves are typically controlled by a control system, which can open and close the valves based on the specific filling requirements.

◊ Sensors:

Sensors are used to detect the presence of a bottle under the filling nozzle and to monitor the fill level of the bottle. They can be infrared sensors, proximity sensors, or other types of sensors. The sensor signals the control system to start or stop the filling process when a bottle is present or when the desired fill level is reached.

◊ Control System:

The control system is the brain of the machine, it manages and controls the different functions of the machine, such as the flow of product, the movement of pistons or valves and the rotation of the carousel, it also manages the communication with the sensors and the operator interface.

◊ Product Hopper:

The hopper is the container that holds the product to be filled, it's typically located above the filling nozzles, and it can be designed to handle different types of products, different volume and pressure.

◊ Capping and Labeling units:

Some machines like monoblock fillers have capping and labeling units integrated into the machine. These units are responsible for applying the caps and labels to the bottles once they have been filled.

◊ Conveyor:

Conveyors are used to move bottles along the production line and to bring them under the filling nozzles. They can be designed to handle different types of bottles and to move at different speeds, depending on the production requirements.

◊ Pneumatic and hydraulic systems:

These systems are responsible for the movement of the pistons, valves, and other mechanical components of the machine, they are controlled by the control system and they require regular maintenance.

Materials for Glass Bottling Machine Manufacturing

The materials used in the construction of the different components of a glass bottle filling machine can vary depending on the type of machine and the product being filled. Below are some common materials used in the construction of different components and their suitability for different types of products:

◊ Stainless Steel:

Stainless steel is a popular material for the construction of filling nozzles, hoppers, and other parts of the machine that come into contact with the product. It is durable, easy to clean, and resistant to corrosion. It is also suitable for a wide range of products, including food and beverage products, pharmaceuticals, and chemicals.

◊ Aluminum:

Aluminum is a lightweight and corrosion-resistant material that is commonly used for the construction of machine frames and other structural components. It is also used for the construction of some parts of the machine that come into contact with the product, such as filling nozzles.

◊ Plastic:

Plastic is used for the construction of some components of the machine that do not come into contact with the product, such as guards and covers. It is lightweight, inexpensive, and easy to clean. However, it is not as durable as stainless steel or aluminum, and it may not be suitable for some products, such as those that are corrosive or high temperature.

◊ Teflon:

Teflon is a type of plastic that is commonly used for the construction of gaskets, seals, and other parts of the machine that come into contact with the product. It is resistant to chemicals and high temperatures, making it suitable for a wide range of products, including food and beverage products, pharmaceuticals, and chemicals.

◊ Rubber and silicone:

Rubber and silicone are commonly used for the construction of seals and gaskets, and other parts that come into contact with the product, they are known for their flexibility, durability, and resistance to chemicals and high temperatures.

◊ Glass:

Glass is used for the construction of bottles, it is suitable for products that are sensitive to light, and it is also used for some laboratory applications where the product needs to be visible.

It's worth noting that the choice of material also depends on the cleaning and sanitation procedures that need to be applied to the machine, as well as the regulations that need to be followed.

Glass Bottle Filling Machine Operations and Maintenance

How Glass Bottle Filling Machine Operations?

Glass bottle filling machines operate by dispensing a product into bottles using a series of nozzles, valves, and sensors. The specific operation of the machine will depend on the type of machine and the product being filled. Below is a general description of how glass bottle filling machines operate:

1. Setting up the machine:

Before the machine can be used, it must be set up with the appropriate nozzles, valves, and sensors for the product being filled. The machine must also be adjusted for the specific size and shape of the bottles that will be used. This may involve adjusting the position of the nozzles, valves, and sensors, as well as the speed of the conveyor.

2. Loading the product:

The product is loaded into the hopper, which is located above the filling nozzles. The product should be at the appropriate temperature and viscosity for the machine to function correctly.

3. Starting the machine:

Once the machine is set up and the product is loaded, the machine can be started. The bottles are loaded onto the conveyor, and they are brought under the filling nozzles in turn.

4. Filling the bottles:

The control system opens the valves, allowing the product to flow out of the hopper and into the bottles. The bottles are filled with a specific amount of product, which can be adjusted based on the desired fill level. Sensors detect the presence of the bottle under the filling nozzle and monitor the fill level of the bottle.

5. Capping and Labeling:

In case of Monoblock filler, once the bottles are filled, they are conveyed further along the production line, where they are capped and labeled automatically, without the need for manual intervention.

6. Making adjustments:

If necessary, the machine can be adjusted during operation to account for changes in the product or the bottles. For example, if the viscosity of the product changes, the flow rate of the product can be adjusted to ensure that the bottles are filled correctly.

7. Cleaning and maintenance:

After the machine is used, it should be cleaned and maintained to ensure that it continues to operate correctly. This may involve cleaning the nozzles, valves, and sensors, as well as lubricating moving parts and checking for wear and tear.

It's worth noting that different types of machines have different operating procedures and different adjustments needed, but the overall process of loading the product, filling, capping and labeling and making adjustments are common among all types of machines. It's important to consult the manufacturer's instructions and to work with a professional when setting up and adjusting a glass bottle filling machine to ensure that it is used correctly and safely.

Common Problems and Solutions of Glass Bottle Filling Machine

Routine maintenance is essential to ensure that a glass bottle filling machine continues to operate correctly and safely. Below are some common maintenance tasks that should be performed on a regular basis:

# Cleaning:

The machine should be cleaned regularly to remove any product residue and to prevent contamination. This may involve disassembling certain parts of the machine, such as the nozzles and valves, and cleaning them with a suitable cleaning solution.

# Lubrication:

Moving parts of the machine, such as gears and bearings, should be lubricated regularly to ensure smooth operation and to prevent wear and tear.

# Inspection:

The machine should be inspected regularly for signs of wear and tear, such as cracks or leaks in the nozzles or valves. Any damaged parts should be replaced immediately to prevent further damage to the machine.

# Calibration:

The machine should be calibrated regularly to ensure that it is dispensing the correct amount of product. This may involve adjusting the flow rate of the product or the position of the nozzles.

# Filter replacement:

The filter, if any, used in the machine should be checked and replaced as needed.

# Pneumatic and hydraulic systems:

The pneumatic and hydraulic systems should be checked and maintained as per the manufacturer's instructions.

In addition to routine maintenance, there are also some common issues that can occur with glass bottle filling machines, and they are:

# Leaks:

Leaks can occur in the nozzles or valves if they are damaged or worn. This can result in the product being wasted and can also cause contamination.

# Incorrect fill levels:

If the machine is not calibrated correctly, it may dispense too much or too little product into the bottles.

# Jamming:

The machine may jam if the bottles are not loaded correctly or if there is a blockage in the nozzles or valves.

# Electrical issues:

Electrical issues can occur if the control system or other electrical components of the machine are damaged or malfunctioning.

# Air pressure issues:

Air pressure issues can occur in the pneumatic system if the air filters are clogged, or if the air compressor is not functioning correctly.

To troubleshoot these issues, you can refer to the manufacturer's instructions, or consult with a professional. It's important to address these issues as soon as they occur to prevent further damage to the machine and to ensure that it continues to operate correctly.

Conclusion

In conclusion, glass bottle filling machines are an essential part of the packaging industry, and they play a crucial role in accurately and efficiently filling bottles with a wide range of products. There are several types of machines available, each with their own advantages and disadvantages. Factors such as production output, product viscosity, and bottle size should be considered when selecting a machine. It's important to work with a professional or the manufacturer to select the best machine for your needs, and to maintain and troubleshoot the machine regularly to ensure optimal performance.