How to choose the filling machine for your engine or motor oil? VKPAK designed and manufactured the some types of Filling Machine for them which are base on the features of the oil and the container specifications, also those fillers are suitable for filling mineral oils, windscreen products, anti-freeze liquid, coolants. This guide focuses on engine / motor oil filling solutions and includes the following:

- What is engine / motor oil?

- Common packaging containers for engine / motor oil

- Selection of engine / motor oil filling machine

- Selection of engine / motor oil capping and labeling machines

What is engine / motor oil?

Motor oil is a lubricant used in internal combustion engines, which power cars, motorcycles, lawnmowers, engine-generators, and many other machines. [From Wiki]

Common packaging containers for engine / motor oil

Today, motor oil in the USA is generally sold in bottles of one U.S. quart (950 mL) and on a rarity in one-liter (33.8 U.S. fl oz) as well as in larger plastic containers ranging from approximately 4.4 to 5 liters (4.6 to 5.3 U.S. qt) due to most small to mid-size engines requiring around 3.6 to 5.2 liters (3.8 to 5.5 U.S. qt) of engine oil. In the rest of the world, it is most commonly available in 1L, 3L, 4L, and 5L retail packages. Distribution to larger users is often in bulk, by tanker truck or in one barrel (160 L) drums.

Selection of engine / motor oil filling machine

Engine / motor oil can range in viscosity from very low to very high, which in turn means the packaging machinery used for the multitude of items in this industry will vary widely as well. For example, when filling an engine / motor oil, weighing and filling machine for engine oil, this type of filler is suitable for filling the engine oils from 500ml to 5000ml jerry can, 20L to 300L pail and drum. the filling quantity was control by the weighing system, no matter the oil viscosity and temperature, the weight is same, but the liquid level will be different for different viscousity type of oils. On the other hand, a pump or piston filling machine may be used for thicker, more viscous oils and lubricants, it is for filling 100ml to 5000ml, it is volumetric type, the measurement is different with the weighing system. These two types of filler are both suitable for filling engine oil, they all have their own advantages, the user can choose the filler accordingly.

Engine / motor oil is one of the many types of liquid products that VKPAK's liquid fillers are designed to handle. We carry many models of motor oil filling machines along with other types of equipment to meet your facility's specific needs, including customizable cappers, labelers, and conveyor systems. We'll assist with product selection to determine which machinery will work best in your facility, and help with installation and setup.

- This machine adopts PLC and touch screen control panel, so it is convenient to set.

- Each filling head has the weigh and feedback system, each filling head can be regulated.

- Photoelectric sensor, approximate switch and other electric elements are of the international famous brands. It ensures no container miss filling. The host machine will alarm if there is any container blocked.

- It applies dive method to fill and it reduces foam; it is suitable for various kinds of filling products.

- The whole machine meets GMP standard, it is easy to clean and maintain, and the parts which contact with the filling material are made of high quality stainless steel. The whole machine is safe, eco-friendly and sanitary. It adapts to various kinds of working places.

The machine adopts PLC programmable control system and weighing feedback system to realize quantitative filling. Applicable to pesticide, chemical, chemical industries and no bubble water fluid filling.

This Machine's Advantage

1. Control system---Mitsubishi PLC control system

2. Operation interface---Two rows of the color operation interface, Convenient operation, stable and reliable.

3. Function improvement---The feeding nozzle is equipped with filling blocker. This machine can realize diving filling according to the material properties. (this function can be selected)

4. Filling show---the filling result is displayed in the unit of weight, intuitive and clean

5. Real-time alarm---Automatic alarming when the fault happens, automatic stopping and alarming when the system appears serious breakdown.

6. Electrical elements---Adopting international famous brand to ensure the remarkable quality, stability and high precision. Machine elements---The parts contacted with the material use the 316 high-quality stainless steel and non-poisonous, anti-corrosive PTEF hose. Other machine parts use the 304 high-class stainless steel.

7. Expansion function----We can carry out special configuration according to the customers’ requirements. (material airtight, heating and sterilizing etc. )

8. Counting detection---Real- time counting, reflecting the output directly.

9. Filling detection---No-bottle no-filling, it will not conduct filling if the bottles are not enough.

10. Function upgrading---We have designed intelligent weighing feedback system to realize the unmanned debugging function.

11. Environmental protection configuration---Equipped with eco-friendly frame, realizing more clean and sanitary operation environment. (this environmental protection configuration can be selected)

12. Interval filling---Minimum filling volume can reach 40ml. We can realize interval filling. (this function can be selected according to the customers’ requirements)

13. Maintenance condition---Fully accords to the GMP requirements, easy to disassemble and clean. Function upgrading---We have designed intelligent weighing feedback system to realize the unmanned debugging function. Filling dose is more accurate, the original ± 1% of filling accuracy increased about 10 times

14. Changing specification--According to the changing of market specifications 5L 20L large-dose packaging range, only in the same machine operation. To save the equipment cost for the customer. when changing filling specifications, just adjust, no need to change any components. easily done.

Bottle type: 1 and 5 liter hdpe can or bottle

Size of bottle: for 5 liter, height=285 to 290 mm, width=190 to 195 mm; thicknessiside width=130 mm; For 1 liter, height=190 to 200 mm, width=35 to 145 mm; thickness/side width=55 mm;

Filling range: 500ml to 5000ml

Filling speed / output: for 5 liter, 15 to 20 can per minute; for 1 liter, 30 to 40 bottle per minute

Filling enor: 0.3% base on 1liter , 0.15% base on 5liter

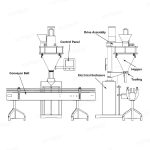

- Automatic Multi-Head Linear Type Engine Oil Filling Machine

- Fully Automatic Cap Dispensing & Capping Machine

- Continuous Induction Foil Sealing Machine

- Automatic Both Side Sticker Labeling Machine

- Conveyor Belt

Automatic Multi Head Engine Oil Filling Machine

1.1 The engine oil filling machine is servo driven, the filling volume is Volumtic by piston type, it is most popular filling machine using in industry oil fields.

1.2 It is handling with oil industry standard, Number of filling nozzles are range from 2 to 16 heads to meet for different capacity needs; Handling engine oil density @30°C to 35°C around 0.800 to 1.100 kg per liter.

1.3 Metal of Machine Construction is 304SS, Contact parts is SS316, Linear Direction of movement left to right.

1.4 Filling and Cut off principle Filling nozzles move downwards and filling from top of the bottle/can.

1.5 The filling nozzles are specially design for oils, anti drops with automatic vacuum sunction system

1.6 The moving up and down of filling nozzles are driving by servo motor, diving filling system is for option.

Fully Automatic Screw Capping Machine

VKPAK design some types of screw capping machine, for the engine oil can/ bottle capping machine, we adapt the linear type one heads or two heads motion tracking capping machine. The capping heads are synchronize moving with bottles, it can gurantee the capping speed and meanwhile avoiding the oil or liquid splash out of bottles and touch the mouth of the bottle. This can gurantee when induction the seals, 100% sealing. The capping heads are driven by servo motor, torgue is adjustable.

The linear synchronize screw capping machine is suitable for any types screw caps, no need to change parts, easy adjustable. The cap feeding system is by using an elevator which can storage around 1000 caps at a time.

The Induction Sealing Machine

We adapt water cooling type system, and it is full automatic, the induction sealing head can automatic lifting.

The Double Side Labeler

Conveyor system

Straight / linear ss 304 conveyor belt of chain type, adjustable guide rail and adjoining with filling, capping, induction sealing and labeling machine. Length of the conveyor belt is long enough to cover the filling, capping, induction sealing and labeling machine as well as min. 8Ft free space for standing provision of can / bottles. Width of the conveyor belt must be wide enough to hold the can/bottle with adjustable guide and rail. Height of the conveyor belt is 850 mm.

Engine / Motor Oil Filling Machine Test Video

Selection of engine / motor oil capping and labeling machines

Following the completion of the liquid filling process, cappers can place custom-sized and -shaped caps to containers. Labeling machines can apply branded labels with custom images and text. To transport products efficiently throughout the production line, conveyors are available with customizable speed settings and configurations. Using a combination of this machinery in your facility, you can benefit from maximized productivity and accuracy throughout the entire packaging process, from start to finish.

Engine / motor oil bottle capping machine, usually choose the following equipment, the specific machine selection needs to be based on the shape of the cap, size, capping method to decide.

Customize Equipment In Your Production Line

VKPAK offers a wide range of customizability for motor oil filling machines and other products in our inventory. Choose from a wide range of configurations, setups, and sizes to complete your liquid packaging system. Our team of experienced professionals can work with you to select the right equipment and design a complete customized system that gives you the best achievable results.

To begin with the design and implementation of a complete system of motor oil filling machinery and other equipment from us, contact VKPAK for immediate assistance. We also offer complementary services in addition to high-quality products to make sure you get the most out of your equipment.