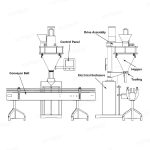

The juice of the mango. Thicker juice is often called “mango nectar”. A non-carbonated beverage flavored by the pulp from mangos. It can be packaged in a variety of containers including glass bottles, plastic bottles, cans, and cartons. In this case we show the working process of a linear mango juice bottle filling machine.

VKPAK mainly offers linear mango juice filling machines with a capacity of up to 8,000 bottles per hour for a single machine; for juice packaging with a capacity of more than 8,000 bottles per hour, a rotary juice filling machine or multiple linear filling machines are recommended.

Linear Mango Juice Bottle Filling Machine

Fruit Juice Filling Machine, Juice Bottling Equipment

An 8-head inverting bottle rinsing machine is a type of packaging equipment used in the beverage or food industry to clean the inside of bottles prior to filling. The machine typically has 8 heads, or spouts, that are designed to hold and invert the bottles as they are being rinsed with water or another cleaning solution. The inverting action helps to remove any residue or contaminants from the inside of the bottles and prepare them for filling with product.

Automatic Linear Juice Bottle Filling Line

Notes on mango juice filling

For mango juice and other food and beverage types of filling in addition to the usual filling considerations there are two important tips as follows.

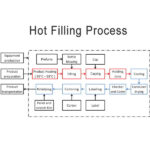

One: sterilisation in the filling process.

It is important to ensure both that the taste of the juice is not affected and that the juice is stored for a longer period of time. Often hot filling technology may be used; to learn more about hot filling technology click on the following articles.

Two: Cleaning and maintenance of the machine.

Maintaining proper sanitation is crucial to prevent contamination of the mango juice. Regular cleaning and sanitizing of the machine and containers should be a part of the operating procedure. Our machines are easy and quick to clean. The tracking rotor pump filling machines can be connected to a professional CIP system for cleaning.

If you are really looking for mango juice filling equipment, please contact VKPAK, our professional team can provide you with the most suitable complete juice bottling line, including bottle unscramblers, bottle rinsers, filling machines, capping machines, labelling machines, sterilization channels and packaging machines (film wrapping machines, case packers, etc.).