Introduction

VK-TFS-100 tube filling and sealing machine is applied for a variety of plastic tube filling and sealing, the maximum operating speed is 160 tubes/ min, and the smooth speed is 110-120 tubes/min (depending on the size of your tube and filling volume). Frequency control, touch screen operation, easy to operate.

The equipment has a high degree of automation, automatic loading, automatic color matching, automatic sealing, batch numbering, and automatic discharging.

Sealing method: Hot air sealing or folding sealing

Applicable tube materials: Plastics tubes, laminated tubes, metal tubes, aluminum tubes

Speed: 80-160 Tubes/min

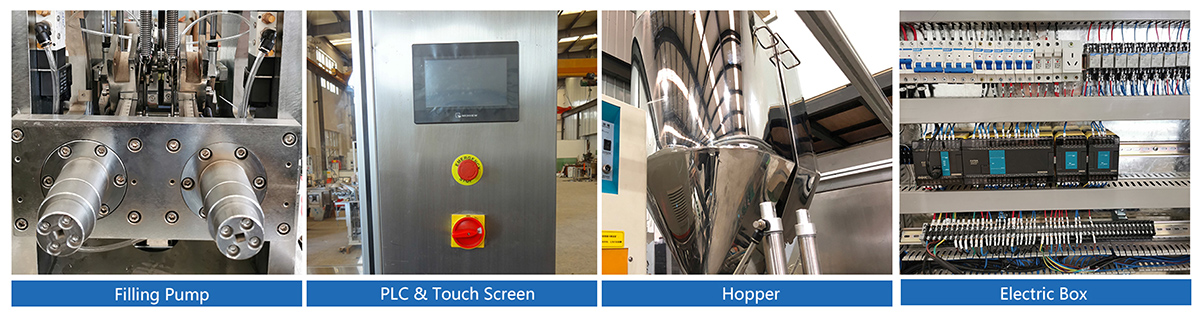

View VideoVK-TFS-100 using rotary type, double filling heads (Can also be upgraded to four heads), high speed. The filling type uses the piston way, and filling accuracy is precision. Filling nozzle anti-drop type, no leak after filling. Easy to adjust the filling volume, and change molds for a different size, and the filling speed can be adjusted. It applies to all kinds of composite tubes, plastic pipe or metal pipe filling and sealing, date printing, cut the tail. The filling, sealing, and printing can be completed at one time.

Parameter

| Model | VK-TFS-100 | |

| Type | Hot Air Sealing | Metal Sealing |

| Power | 380V 50Hz | 380V 50Hz |

| Max KW | 9.5KW | 2.3KW |

| Average KW | 6.5KW | 1.7KW |

| Volume of Comoressed Air | 40 to 60m³/h | 10 to 20m³/h |

| Water Consumption | 6L/min | |

| Speed | 80 to 150 tubes/min | |

| Fill Volume | 1.5 to 300ml | |

| Fill Precision | ≤1% | |

| Soft Tube Length | 50 to 250mm | |

| Soft Tube Diameter | 10 to 50mm | |

Working Video

Features

1. Automatic feed the tubes into the tube holder through the infeed box, the tube is filled with stainless steel reciprocating piston pump after correction.

2. In order to make no leakage when filling, we use Japan imported seal rings.

3. We use air blowing for tail cutting after filling, no tube no sealing.

4. Machine structure advanced, advanced configuration, with convenient operation, easy maintenance, easy cleaning and so on.

5. Can stand-alone use, but also connect with automatic cartoning machine, automatic shrink film machine be a packaging line.

6. The surface of table and the door under the stage of the machine are made of stainless steel 304, there are 38 pcs of tube holder on the synchronous pulley.

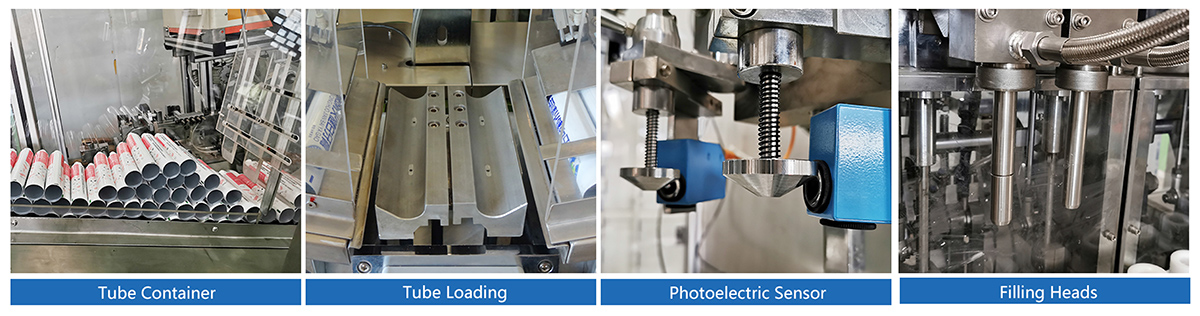

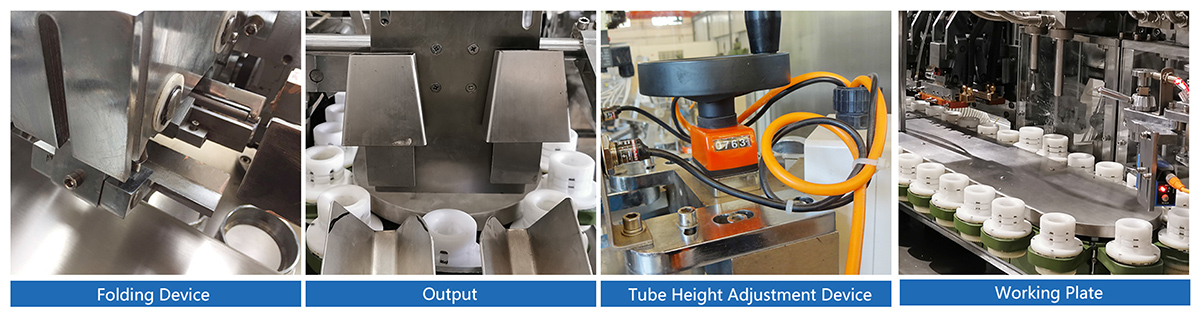

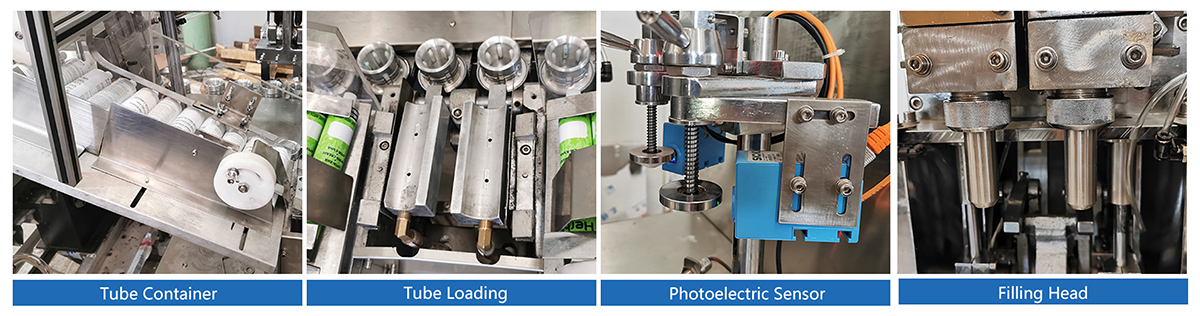

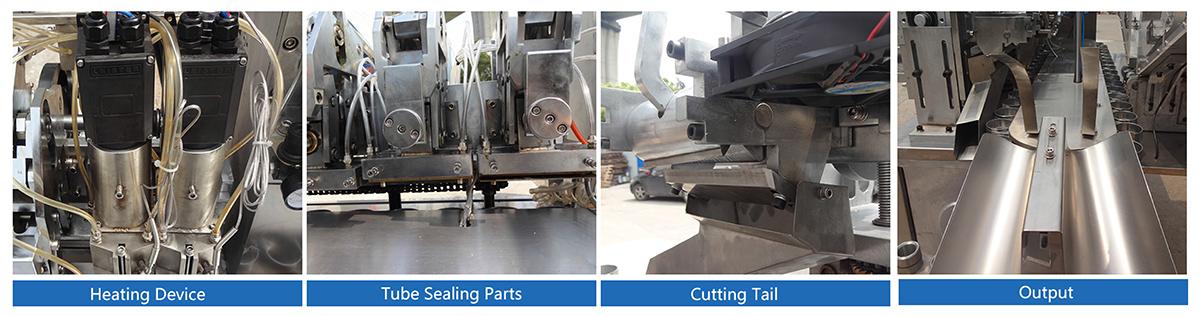

Images

Working Process

Plastic Tube Filler And Sealer: Tube Container → Automatic Tube Loading → Photoelectric Sensor Positioning → Fluid Filling → Tube Hot Melting → Tube Sealing & Date/Batch Number Coding → Tube Checking and Rejecting →Trimming → Output

Metal Tube Filler And Sealer: Tube Container → Automatic Tube Loading → Photoelectric Sensor Positioning → Fluid Filling → Folding Tube → Tube Checking and Rejecting → Output

Machine Options

Plastic Tube Filler And Sealer:

- External Chiller System, Water Cooler

- Laminated Hopper Insulation Device

- Alien Sealing Device (wave-shaped sealing device; arc-shaped sealing device; T-type punching and sealing devices, etc.)

- Automatic Feeding Pump

- Finished Tube Output Conveyor

Metal Tube Filler And Sealer:

- Laminated Barrel Insulation Device

- Hopper Internal Mixing Device

- Multicolor Filling System

- Less than 3ML / Branch Dedicated Filling Device

- Automatic Feeding Pump

- Finished Tube Output Conveyor

VK-TFS-100 For Metal Tubes Details

VK-TFS-100 For Plastic Tubes Details

VK-TFS-100 High Speed Metal Tube Filling And Sealing Machine Advantages

- Host with frequency control.

- One machine, it can be achieved through different adjustable triple tail or 5-folds..

- Robot folding both flexible and stable, filling and sealing tail design is an open and clean, maintenance is very convenient.

- Color positioning, selection of German, while accompanied by a high-precision drives and stepper motor (very high require-ments on the standard configuration Servomotor), to ensure the correct position graphics.

- Note phased material filling nozzle deep inside the tube, while there is a bottom-up filling process is complete filling and sealing, no leakage or overflow. Machine is suitable for a variety of different physical and chemical properties of the filling mate¬rial requirements. Filling volume fine hand wheel placed in the external body, tight regulation and very convenient to ensure filling accuracy ± 1%, cost savings and truly accurate measurement.

- The structure is compact, self-control, transmission closed.

- It is accomplished by a pneumatic supply pipe, wash pipe, accurate and reliable.

- Rotary tube mold with electric eye control center positioning device, the use of photoelectric sensors complete the automatic positioning.

- Adjusting easy disassembly, particularly suitable for the production of large diameter tube multi-standard user, easy adjust-ment and quick.

- Material contact parts made of 316 stainless steel, clean, sanitary, in full compliance with the requirements of GMP.

- The machine speed by inverter control and adjustment.

- Direct and convenient height adjustment.

- Tube filling volume by adjusting hand wheel adjustment, and convenient.

- Equipped with safety devices, door stop, no tube no filling, overload protection.

- Transmission partially closed in the platform below, safe, reliable, non-pollution

- Filling and Foldling parts mounted on the platform above semi-closed static-frame viewing hood, easy to observe, easy op-eration, easy maintenance.

- Stainless steel touch switch operation board.

- Photoelectric standard workstations, high-precision sensor, stepper motor control tube pattern in the correct position;

- No filling leak, the air blow-off device blew cream tail. (This is our patent)

- Ductless not filled.

- Typing yards workstation will automatically code printed on the technical requirements of the position.

- Fault alarm, overload shutdown.

- Count and quantify downtime.

VK-TFS-100 High Speed Plastic Tube Filling And Sealing Machine Advantages

- Anti-leak filling nozzle deep into inside of hose, while there is a bottom-up filling process is complete when filling and sealing, no leakage or overflow. Machine is suitable for a variety of different physical and chemical properties of the filling material requirements. Filling volume fine hand wheel placed in the external body, tight regulation and very convenient to ensure filling accuracy ±1%, cost savings and truly accurate measurement.

- Mechanical drive, each parts connect with gear or cam, machine running smoothly and stable, no noise.

- Color positioning, selection of German, while accompanied by a high-precision drives and stepper motor (very high re-quirements on the standard configuration servo motor), to ensure the correct position graphics.

- The structure is compact, self-control, transmission closed.

- Easy to change tube holder for different tube diameter.

- Material contact parts made of 316 stainless steel, clean, sanitary, in full compliance with the requirements of GMP.

- The machine speed by inverter control can be adjustable.

- Height can be adjusted directly and conveniently for different tubes.

- Filling volume can be adjustable by double cylinder, easy to adjustable.

- Equipped with safety devices, door stop, no tube no filling, overload protection.

- No filling leak, the air blow-off device blew cream tail. (This is our patent)

- Sealing temperature use (Leister hot air gun) tail pipe internal heating, cooling external cooling device configuration.

| NO. | ITEMS | BRANDS |

| 1 | Touch Screen | Taiwan WEINVIEW |

| 2 | Frequency Converter | China Wei Chuang |

| 3 | PLC | Japan Mitsubishi |

| 4 | Photocell Eye | Germany SICK |

| 5 | Temperature Controller | America Honeywell |

| 6 | Main Motor | Taiwan Taiqi |

| 7 | Optoelectronic Switch | American Banner |

| 8 | Cylinder | Shanghai |

| 9 | 304 SS | Shanghai Baosteel |