Introduction

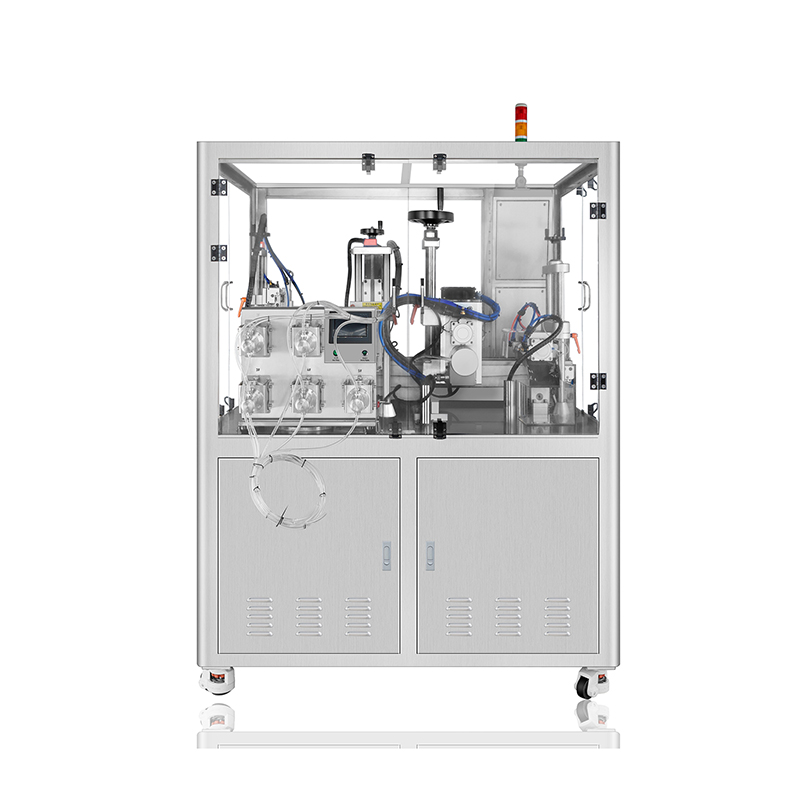

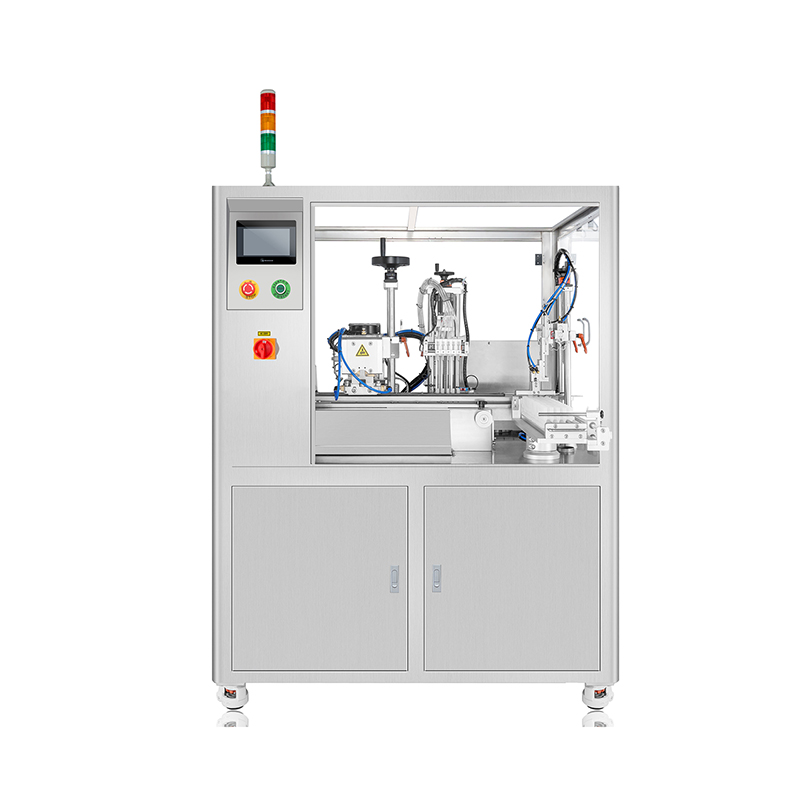

A monodose strips filling and sealing machine is a piece of equipment designed to automate the process of filling individual doses of a product into monodose strips and subsequently sealing them. These machines are commonly used in industries such as cosmetics, and personal care to efficiently produce unit-dose packaging. The working process is as following:

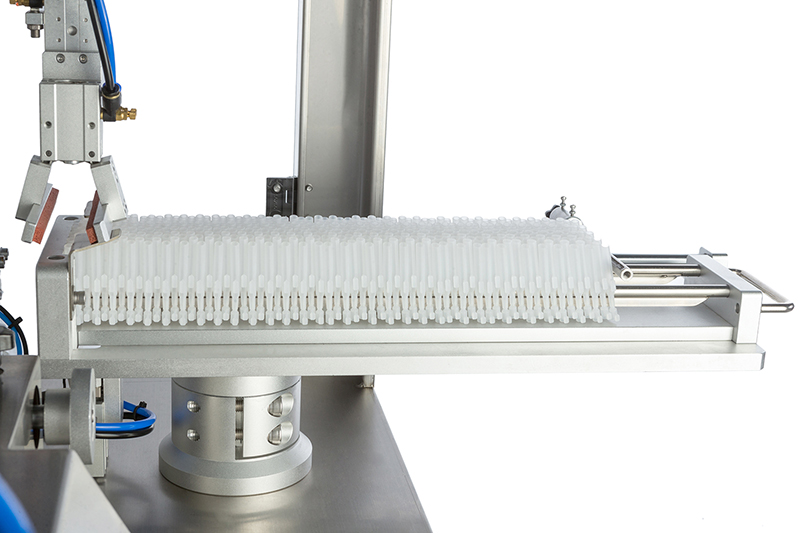

1. Mono dose strip tube feeding onto the machine automatically

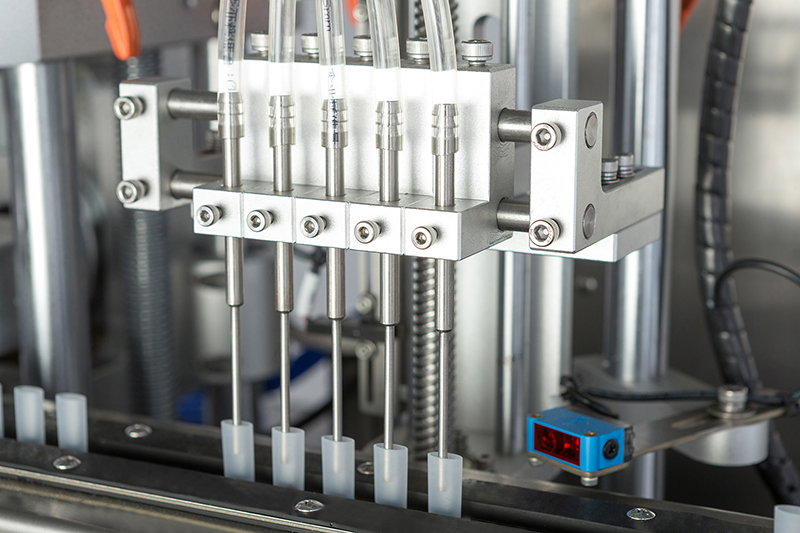

2. Liquid or cream, paste filling into the tube by filling pump (the pump will be different as per the product viscosity)

3. Ultrasonic tube sealing

4. Filled and sealed tube discharge

Sealing method: Ultrasonic sealing

Applicable tube materials: plastic tubes, laminated tubes

Speed: 15-20 Pcs/min

View VideoDesigned with precise ceramic pump, this machine suits for packing eye drops, essence.

The individual eye drops filling and sealing machine is equipped with touchscreen, making it convenient to set and adjust working parameters.

1. Can feed single-dose strip,fill liquid,seal and trim strips at one machine.

2. With ceramic pump,the machine has high filling precision.

3. The machine can be customized according to your production need.

Working Video

Advantages

1. It adopts ultrasonic sealing machine , good for difference products, such as food, medical, cosmetic products. It will not hurting the products;

2. Overload protection, phase separation protection, power-fail protection;

3. Large ultrasonic output power to ensure the sealing quality of various tube size and material;

4. With tube end trimming;

5. Easy change working mold for difference tube diameter;

6. Adjustable tube length;

7. Machine include a ceramic pump filler.

Parameter

| Model | VK-TFS-005U |

| Frequency | 20kHz |

| Power | 2600W |

| Power supply | AC220V/110V |

| Filling Range | 0.3-10ml Rotary Valve Plunger Pump / 1-10ml Valveless Plunger Pump |

| Filling accuracy | ±0.05g |

| Capacity | 15-20pcs/min |

| Tube diameter | 1-7dose/50-135mm |

| Tube height | 50-150mm |

| Working pressure | 0.6 MPa |

| Size | L1300*W1300*H1950mm |

| N.W/G.W | 514kgs |

Main Features

1. This machine automatically completes a series of actions such as tube feeding, filling, tail sealing, tail cutting, and finished product delivery. It is saving labor and reducing production costs;

2. Equipped with safety devices and overload protection;

3. Servo motor precise positioning;

4. Ultrasonic technology is used for sealing, and the sealing effect is stable and long-lasting; the sealing line is clear and does not deform;

5. Independent research and development of digital ultrasonic automatic frequency tracking electric box, no need to manually adjust the frequency, increase the automatic power compensation function, and will not cause the power of the machine to drop due to long use time. The power can be adjusted freely according to the material and size of the hose, the output is stable, the failure rate is extremely low, and the service life is longer than that of ordinary electric boxes;

6. It adopts PLC touch screen control,equipped with a fault alarm system, and the fault information is displayed on the touch screen, which is clear at a glance, and can quickly locate and solve problems;

7. The whole machine is made of 304 stainless steel, acid and alkali resistance, corrosion resistance;

8. The machine is equipped with an automatic identification system, no tube, no filling and no sealing, reducing the loss rate of the machine and mold;

9. Five-head precision ceramic pump filling machine, filling accuracy ± 0.02ml;

10. The design of the sealing mold adopts an embedded structure, which is convenient for disassembly and debugging;

11. The processed parts are all processed by grinding and chamfering.

Drawing

Images

Application

Applicable Products: Eye drops, essence, serum, nose drops, liquid solution.

Applicable Industries: Pharmaceutical, cosmetic, chemical industries.

Detail Images

This structure is designed for feeding single-dose strips automatically, which helps to save labor cost. It can be customized according to your product size.

Automatic tube feeding device

Equipped with ceramic pump, this machine can fill liquid precisely, which suits for filling essence, eye drops. The diving nozzles can prevent liquid from splashing out during filling, ensuring production quality.

Equipped with ceramic pump, this machine can fill liquid precisely, which suits for filling essence, eye drops. The diving nozzles can prevent liquid from splashing out during filling, ensuring production quality.

5 Filling Nozzles: Filling at one time, more efficiency

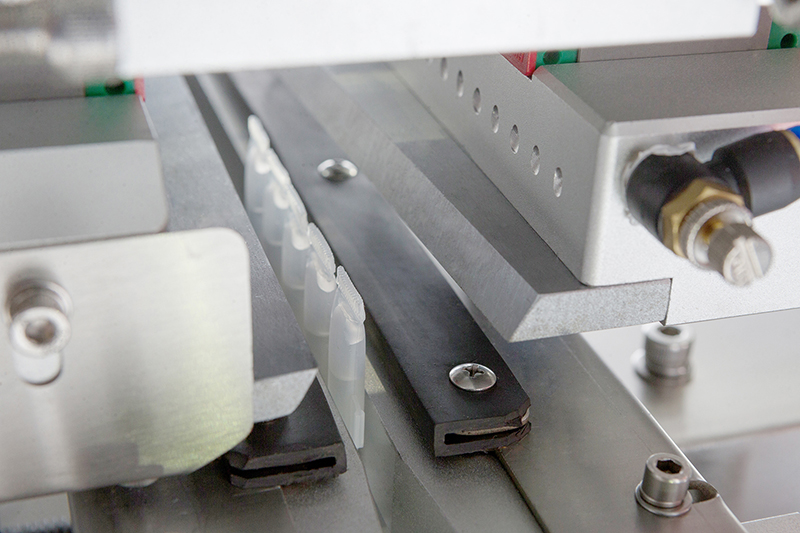

Adopting the way of ultrasonic sealing, this machine can seal the single-dose strips well. The ultrasonic frequency can be adjusted as production need.

The default trimming method is flat cut, which gives a flat cut tail affect. The trimming height is easy to adjust to meet different needs. And the replacement is convenient.

The default trimming method is flat cut, which gives a flat cut tail affect. The trimming height is easy to adjust to meet different needs. And the replacement is convenient.| Ultrasonic system | Digital auto frequency Tracking |

| Main Machine PLC | Mitsubishi, Japan |

| electric relay | Omron, Japan |

| Touch Panel | WEINVIEW,China Taiwan |

| Photoelectric switch | Omron, Japan |

| Air cylinder | AirTAC,China Taiwan |

| Solenoid valve | AirTAC,China Taiwan |

| Transducer | CN |

| Air source processor | AirTAC,China Taiwan |

| Servo Motor and driver | Lichuan,CN |

| Ceramic pumps HMI and PLC | Coolmay,CN |

| Stepping motor and driver | Leadshine,CN |