Introduction

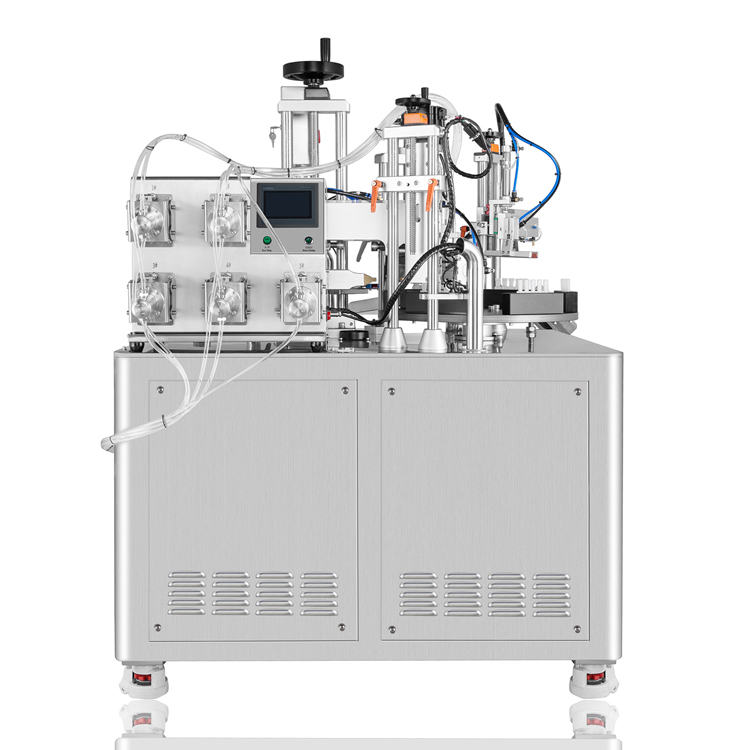

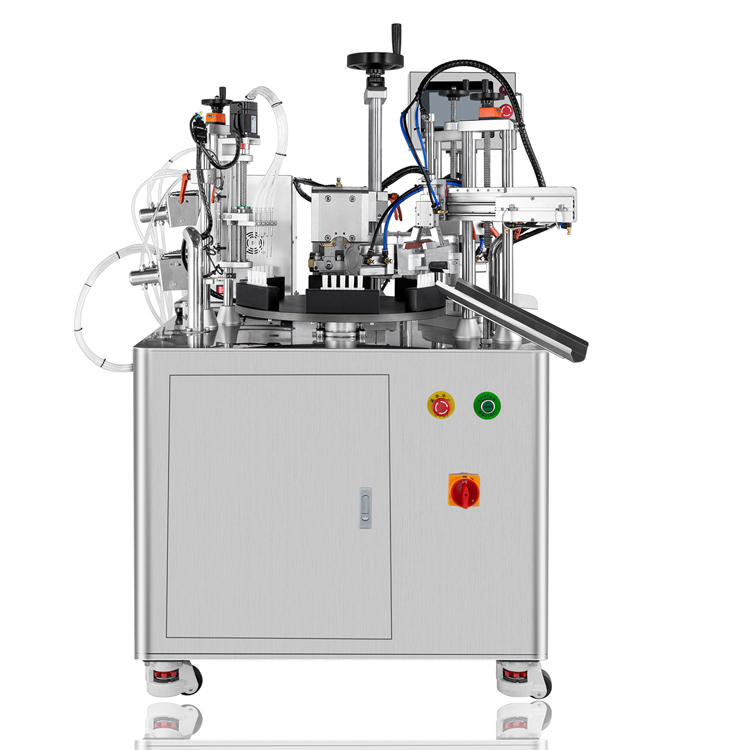

VK-TFS-005 is a semi automatic single dose (also called mono dose) tube filling and sealing machine. It is equipped with ceramic pump, which can fill liquid accurately. The fixing mold can be customized according to product size. This machine is widely used in cosmetics, daily chemical industries. The working process is as following:

1. Mono dose strip tube feeding onto the machine by hand;

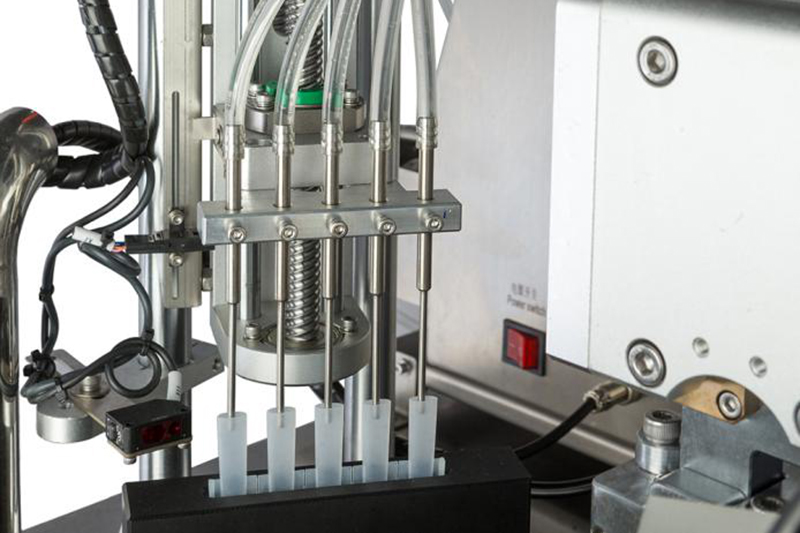

2. Liquid or cream, paste filling into the tube by filling pump( the pump will be different as per the product viscosity);

3. Ultrasonic tube sealing;

4. Filled and sealed tube discharge.

Sealing method: Ultrasonic sealing

Applicable tube materials: plastic tubes, laminated tubes

Speed: 10-13 Pcs/min

View VideoThe machine is equipped with high quality electric eye, which can detect soft tube and control the machine to seal and trim soft tube. Reduce production error.

The fixing mold can be customized according to monodose tube size. This machine is also with clamping function which can clamp finished products after producing.

Working Video

Parameter

| Model | VK-TFS-005 |

| Frequency | 20 kHz |

| Power | 2600W |

| Power supply | AC220V/110V |

| Filling Range | 0.3-10ml Rotary Valve Plunger Pump / 1-10ml Valveless Plunger Pump |

| Filling accuracy | ±0.05g |

| Capacity | 10-13 pcs/min |

| Tube diameter | 1-7 strip/length 50-140mm |

| Tube height | 50-150mm |

| Working pressure | 0.6 MPa |

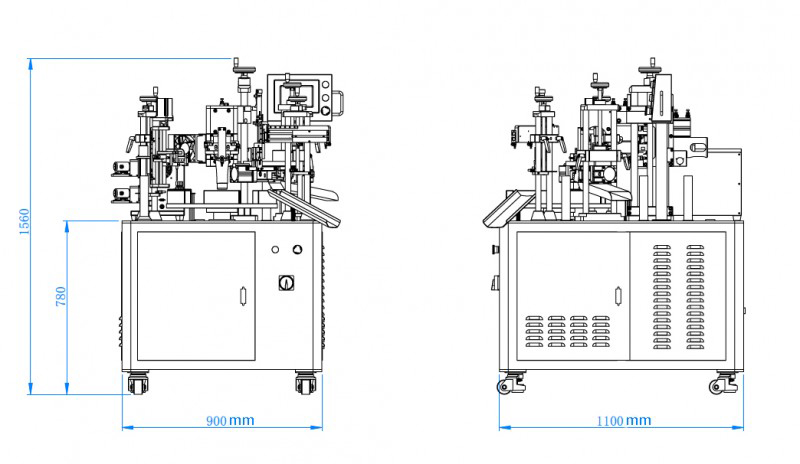

| Size | L1300*W1300*H1550mm |

| N.W/G.W | 330kgs |

Main Features

1. Machine is specially designed for 5 in 1 tubes, suitable for mass production of 5 in 1 tubes.

2. Manually tube feeding, automatic filling, sealing, end trimming.

3. Adopts ultrasonic sealing technology, no need warm up time, more stable and neat sealing, no distortion and low reject rate less than 1%.

4. Independent R & D for digital ultrasonic automatic tracking electrical control box, no need manual adjust the frequency, with power auto compensation function, avoiding the reduction of power after long time use. Could freely adjust the power based on tube material and size, stable and minimum the fault rate, extend the life span than the normal electrical box.

5. PLC with touch screen control system, providing friendly operation experience.

6. Made of 304 stainless Steel, acid and alkali resistance, corrosion resistance.

7. Standard equipped with peristaltic pump filling system, high accuracy filling, and suitable for liquid filling.

8. No tube, no fill, no tube, no seal function, reducing the machine and mould loss.

9. Cam indexing system could position precisely for six working stations.

Drawing

Images

Application

The strip mono dose tube for single use is made at 1ml, 2ml, 3ml, 5ml and 10ml.

The tube type that can be applied on the machine are: plastic tube, aluminum plastic tube, composite tube

It is used for packing essential oil, serum, gel, eye cream, sample product, pet supplies etc.

Detail Images

| Ultrasonic system | Automatic frequency tracing |

| Frequency converter | Panasonic, Japan |

| PLC | Mitsubishi, Japan |

| electric relay | Omron, Japan |

| Touch Panel | WEINVIEW,China Taiwan |

| Inductive switch | Omron, Japan |

| Air cylinder | AirTAC,China Taiwan |

| Solenoid valve | AirTAC,China Taiwan |

| Transducer | CN |

| Motor | CN |

| Partitioner | JOUDER,China Taiwan |

| Air source processor | AirTAC,China Taiwan |