Salsa is a type of sauce, mostly packaged by jars; similar to sauce, VKPAK recommends the use of piston filling machines.

Looking for salsa filling machinery that can improve your production line in the long-term? VKPAK carries many different types of liquid fillers, including machinery for salsa. We carry liquid filling machines for a wide variety of liquid products, including food and nonfood items. We can help you find the right machinery based on your product's viscosity, your facility's space requirements, and other factors.

Brief introduction of salsa

Salsa is a variety of sauces used as condiments for tacos and other Mexican and Mexican-American foods, and as dips for tortilla chips. They may be raw or cooked, and are generally served at room temperature.

Salsa is a common ingredient in Mexican cuisine, served as a condiment with tacos, stirred into soups and stews, or incorporated into tamale fillings. Salsa verde is made with cooked tomatillos and is served as a dip or sauce for chilaquiles, enchiladas, and other dishes.[From Wiki]

Salsa filling machine selection

Salsa is mostly packaged in glass or plastic jars with lugged or threaded lids.

When you are bottling salsa there are several types of filling machines you may choose.

VKPAK designs and builds filling machines and packaging equipment for salsa.

Our salsa liquid filling machines are designed to meet the changing needs of the salsa industry. We manufacture the ideal machinery to handle your salsa filling needs and meet your production goals. Our liquid filling machines are designed to handle many liquid products ranging from low to high viscosity. Smooth to chunky salsa products can be bottled using our equipment, among many other liquid food products. For improved performance throughout your facility, you can combine salsa filling equipment with other equipment that we offer.

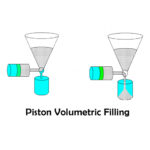

The salsa bottling equipment is a piston filling machine for filling different viscosity sauce or liquid products. The salsa bottling equipment uses a cylinder to push the piston, uses high-quality pneumatic components, and can be quantitatively filled.

The salsa bottling equipment is suitable for filling viscous materials such as various sauces (such as tomato sauce, salsa sauce, and fruit jam), high concentration and quantitative filling of pulp or granule beverages and even pure liquids.

Salsa Filling Machine Video:

Salsa Filling Machine Features:

1. The machine can be customized with different capacity hoppers, add heating and stirring equipment, adding liquid level controller, accurate filling and easy adjustment.

2. The parts contact with the material is made of stainless steel, easy to disassemble, easy to clean, in line with food hygiene requirements.

3. The filling volume and filling speed are simple to adjust, and if there is no bottle, will not filling .

4. The liquid level is automatically controlled to feed, and the appearance is beautiful.

5. You can quickly adjust and replace bottles of different shapes and sizes without changing parts.

6. The filling nozzle of the bbq sauce bottling equipment is equipped with an anti-drip device to ensure that the filling does not drip.

Note:

During operation, the salsa bottling equipment is affected by the following factors:

1. Filling accuracy: Compressed air stability, material uniformity and filling speed.

2. Filling speed: Material viscosity, cylinder stroke, filling nozzle size and conveyor speed.

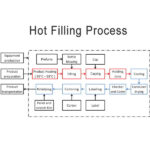

Install A Complete Salsa Filling Machine System

After the liquid filling process is completed, you can utilize a system of cappers to place liquid-tight and airtight caps to keep salsas free of contaminants and avoid leakage, and labelers to apply custom-printed product labels that effectively display your brand and nutritional information. A system of conveyors can transfer product containers throughout the production line with consistent efficiency. A custom liquid packaging system using our state-of-the-art equipment can add years to your production line and maximize profitability.

Salsa Capping Machines

Salsa bottle capping machine, usually choose the following equipment, the specific machine selection needs to be based on the shape of the cap, size, capping method to decide.

Salsa Labeling Machines

Salsa bottle labeling machine, usually choose the following equipment, the specific machine selection needs to be based on the shape of the container, the size of the container, label size to decide.

Design A Custom Production Line

VKPAK allows customers to design custom liquid packaging configurations that adhere to the demands of their specific application. Facilities with particularly limited space can still benefit from a complete packaging machine that's shaped to fit within tighter confines, with the same level of quality as larger production lines. You can utilize a production line with custom equipment that keeps your liquid packaging operations in-line with your business's standards for quality.

If you want to get started designing your custom production line, contact VKPAK. We'll assist with the design and implementation of a customized system of salsa filling equipment and other packaging machinery.