What is a Lug Cap?

Lug caps are a type of metal cap used to seal glass bottles and jars, using a unique threading system. Rather than having a continuous thread, these caps have lugs–angled metal tabs positioned on the inside of the cap’s skirt that grip the threads of the container as the cap is twisted into place. The primary advantage of lug caps over continuous thread caps is that they only have to be twisted 1/2 turn or less to close or open.

Lug caps are often used to seal hot-filled food products such as pasta sauces and salsa, or beverages such as bottled iced tea, packaged in glass bottles and jars. Following capping, as these products cool a negative pressure is created, sealing the lug cap even more securely.

Types of Lug Capping Machines

At present, the main capping methods in the market are spindle capping, chuck capping and snap capping. For lug capping, snap capping is obviously unreasonable. We currently offer the following types of lug cap screwing machines: Vacuum capping machine, Spindle capping machine, Chuck capping machine.

Vacuum Lug Capping Machine Working Process:

- In Vacuum Lug capping machine, the filled bottles to be capped are conveyed to the carrier chain of the main unit by the conveyor and then into the machine.

- Caps are automatically arranged with opening downwards in the cap feeder and taken to the guide rail in the pre-sealing area along the chute one by one.

- The chute is provided with a steam ejecting pipe to soften the seal ring in cap. A Cap is left on the neck of each bottle passed the guide rail and pre-sealed under the application of pressing foot and rubber block. Then it comes to the underside of the differential flat belt pressure plate of the sealing assembly and is tightened by the two differential flat belts to twist cap.

- Before capping, the bottle passes the steam ejection area first and displaces the air under normal pressure in the top clearance at the bottle mouth with high-speed steam. After capping, the cooling water pipe sprays cold water on its cap to cool down the bottle to vacuum it.

- During the entire process from pre-sealing to sealing, the bottle is clamped by a pair of V-belts synchronizing with the carrier chain so that the bottle can go forward smoothly and will not turn.

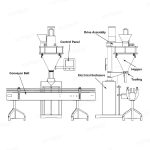

Automatic Spindle Lug Capping Machine

Like any person or machine that is good at a job, spindle lug capping machines, once correctly set up, make the sealing or closing process look easy. The concept seems simple enough, bottles and caps pass through several sets of matched disks, each set of disks adding torque to tighten the cap. Automatic spindle lug cappers can continuously, and reliably, tighten caps throughout an entire production period. There are, however, more than a couple of tricks to the set up process that ensure the effectiveness of the capping machine.

Continuous capping would not be possible without a continuous supply of caps. Popular delivery systems for automatic spindle lug cappers include cap elevators and vibratory bowls. Generally, the operator of a packaging line can dump a bulk supply of caps into a hopper to keep the machine running continuously. But even with the cap supply, the delivery machines must be fine tuned to properly function. The first step in pulling maximum performance from the capping equipment will be properly setting up the cap delivery system. Cap elevators will need to be at the right tilt or slant to properly carry closures to the chute and deliver them to the capping machine. Upside down, twisted or turned caps will create jams or will simply not create the desired seal. Improperly oriented caps will fall back to the hopper to start the elevator climb once again. Air jets may also be employed in the delivery or rejection process. Sorting bowls like the vibratory bowl will usually include vibration controls and air jets to move caps up the bowl and also reject those that are improperly aligned.

So now that all the set up has been completed to ensure the cap is properly delivered, the manufacturer of the lug capping machine must also ensure that the bottle stays stabile during its journey through the machine. While the cap may continue to be stabilized through the entire machine with a bar running between the sets of spindles, the bottle is stabilized using a set of gripper belts. These belts must be adjusted to provide support at the correct spot to avoid tipping the bottle, slowing the bottle or otherwise interfering with the containers progress through the bottle lug capper. The belts can be raised, lowered and moved in or out to accommodate the bottle being run. In some cases, two sets of gripper belts may be used to provide additional support. For example, a top heavy bottle, an oddly shaped bottle or simply an extremely tall bottle may require two sets of belts to avoid disrupting the bottles progress.

Once the bottle and cap are joined and both are moving slowly into the capping zone, a few more adjustments will be necessary to ensure the consistency and reliability of the bottle capper. The spindle disks will obviously need to contact the bottles at the correct point and with the correct pressure to tighten as desired. Spindle disks can easily be adjusted up, down, in and out. Some applications will use a clutch on the last set of disks to add greater control of the torque being used to tighten the seal. If each of these adjustments are made correctly, then the automatic lug cap sealing machine will, at last, cap bottles at a continuous pace during the production run.

Chuck lug capping machines are often preferred when customers are looking for a capping system that will minimize cross-threading and provide better controlled and higher capping torque.

One of the limitations that most chuck capper machines have is that they require changeparts for each bottle size as well as additional parts for chutes and capping chuck jaws.

A good single head chuck capping systems will run up to 30 bottles per minute but it will slow down for big caps or difficult to handle bottles. For higher speeds you will need a multihead capping machine, a good rule of thumb to calculate how many capping heads you need is 2,000 bottles per hour per capping head, so if you want to run 12,000 bottles per hour = 200 bottles per minute you will need at least a 6 head rotary chuck capper.