Clamshell packaging is commonly used to store food products like baked goods and fresh fruit. If you package bakery items, confectionary, fruits or vegetables, sandwiches, sushi, salads, meat, deli or other ready to eat fresh foods in clamshell packages and need to apply a pressure sensitive label or seal on the clamshell package, we have the best clamshell labeling machine for your application.

Our clamshell labeling machines allow users to quickly and efficiently apply labels to clamshell packaging, helping companies prevent errors and improve supply chain efficiencies. These crisp, clear labels are smoothly applied to ensure text, barcodes, and branding are easy to read.

Clamshell labelers are complete labeling systems which include the labeler, conveyor, sensors and controls in one easy to use package. The labeling heads are servo-driven and synchronized with the encoded conveyor drive. These clamshell labelers apply pressure sensitive labels and are super easy to operate, efficient and accurate in applying clear and opaque pressure sensitive labels.

Below we will list some of the clamshell labeling machine videos that VKPAK has provided.

Automatic Clamshell Flat Labeling Machine, Single Side Labeler Machine

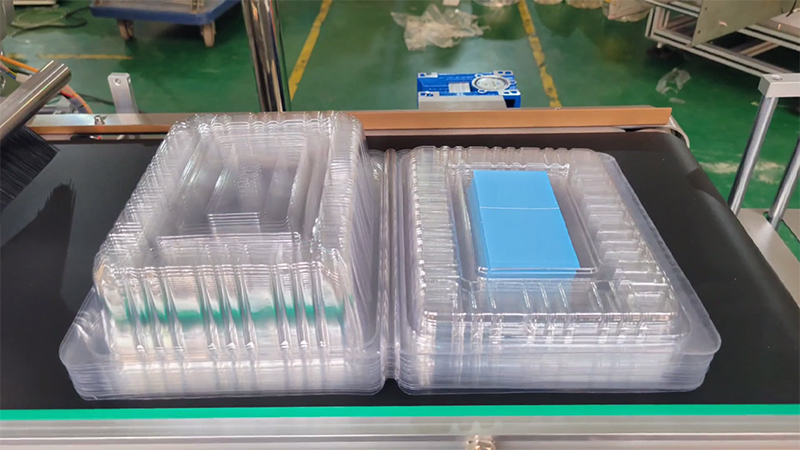

The machine is designed to apply pressure-sensitive labels to clamshell bakery or food containers. Many food packaging operations are now using clamshell containers for bakery goods, pre-made meals, fresh produce, and much more. The labeller is made of 304 stainless steel and anodized aluminum and carefully treated to guard against the effects of harsher environments. This durability translates into a solid choice for labeling machine longevity.

Model: VK-FTL

Labeling speed (pcs/min): 20-100 (relate to material and label size).

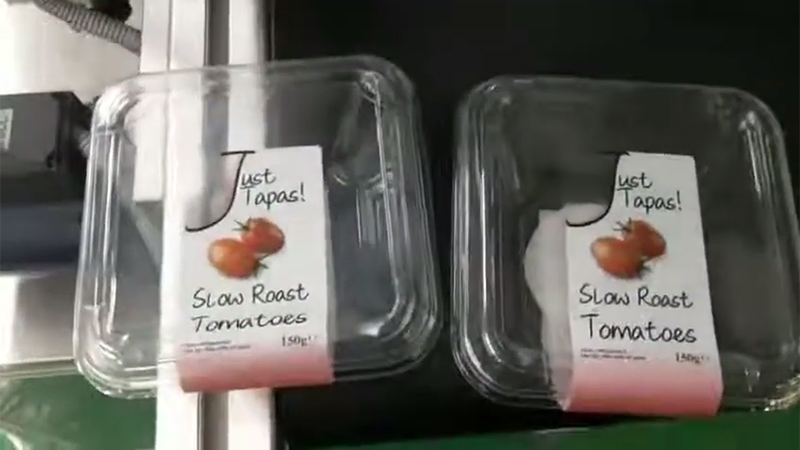

C-Wrap Label Applicator Machine For Clamshells

The c-wrap label allows the bottom panel of the package to be labeled with nutrition, ingredient, and allergen information, while the top section includes branding and marketing messaging. A c-wrap label also provides a tamper evident solution for clamshell type packages.

Labeling speed (pcs/min): 30-80 (relate to material and label size).

Clamshell Labeling Machine, Top & Bottom Labeling Machine Label Applicator

The Clamshell labeling machine is capable of applying top and bottom label to the clamshell and also a C Shape and L shape labeling. The unique wipe-on design allows labels to secure on the container with excellent accuracy. This machine can also be altered to allow a full wrap or undertuck/tamper-evident seal application.

Model: VK-TBL

Labeling speed(pcs/min): 30-100 pieces/minute (relate to material and label size).

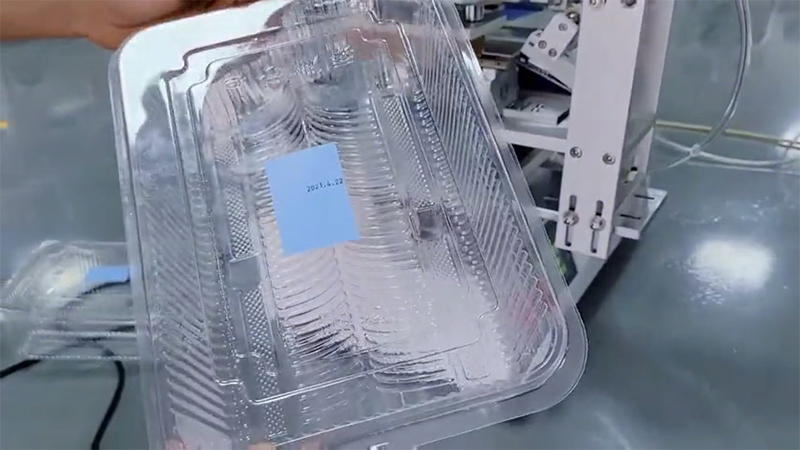

Semi Automatic Clamshell Sticker Labeling Machine

Model: VK-T802/VK-T803

Labeling speed (pcs/min): 15-30 (relate to material and label size).

With the growing application of the clamshell packaging food industry, clamshell packaging machines are getting popular among various manufacturing industries. A lot of major companies are moving towards automation due to increased demand and for keeping a regular supply of products, clamshell labeling machines are installed. With the varying designs of labels, manual labeling becomes a lengthy process and hence automation using clamshell labeling machines saves time and overall manufacturing costs. Hence, with the increased adoption of clamshell packaging, the clamshell labeling machine market is estimated to grow in the future.

Clamshell container labeling machines label the containers from the top, bottom, or side as per the need. Clamshell labeling machines apply the adhesive labeling on the container with minimum pressure without hampering the product and its packaging. VKPAK offers different types of clamshell labeling machines. If you are looking for a clamshell labeling machine, please contact us and our engineers will provide you with the best labeling solution.

We not only offer quality equipment, we listen, we adapt to your needs. We offer advice, we look for the best approach to your project. We recommend the most cost effective equipment without sacrificing quality. It is our responsibility to ensure that all our customers receive every attention to detail to make the installation successful, cost-efficient and profitable.