Introduction

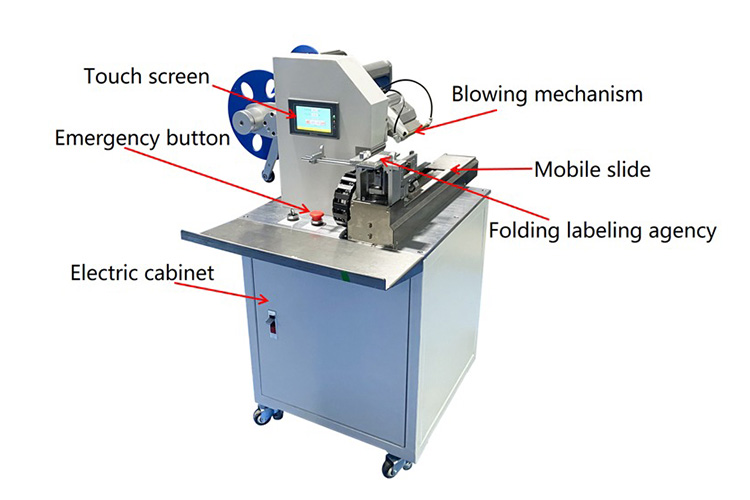

VK-T807 applicable to the folding of various wire labeling. Labeling accuracy up to ±0.3mm. Such as: Connecting pipe, the wire, the date line, the charger line etc. This machine is an semi automatic device that applies the label film on the tape backing paper to the cable. This machine has a wide range of applications. The electronics industry, wire and cable industry, food and other industries have good labeling effects, easy operation, and label roll easy to replace, suitable for labeling cables of various specifications.

Applicable labels: self-adhesive labels, warning labels, barcodes, manual labels, etc.

Applicable products: Folding and labeling round/elliptical/flat wire rods in half.

Application industry: Widely used in the electronics industry, wire and cable industry, food and other industries.

Application examples: data cables are folded in half and labeled, power cords are folded in half and affixed with warning labels.

View VideoParameter

| Model | VK-T807 |

| Labeling Accuracy | ±0.3mm |

| Labeling Speed | 15-30pieces/minute |

| Applicable product size (Diameter) | 1mm~8mm |

| Applicable Label Size | Length: 10-50mmBottom paper width: 30mm ~120mm |

| Weighing range | 10-1500g (can be customized) |

| Inner Diameter Of Label Roll | 76mm |

| Label Outer Diameter | 250mm |

| Overall Size (length*width*height) | 600mm*600mm*1200mm |

| Applicable Power Supply | 110-230V |

| Total Weight | 80Kg |

Main Features

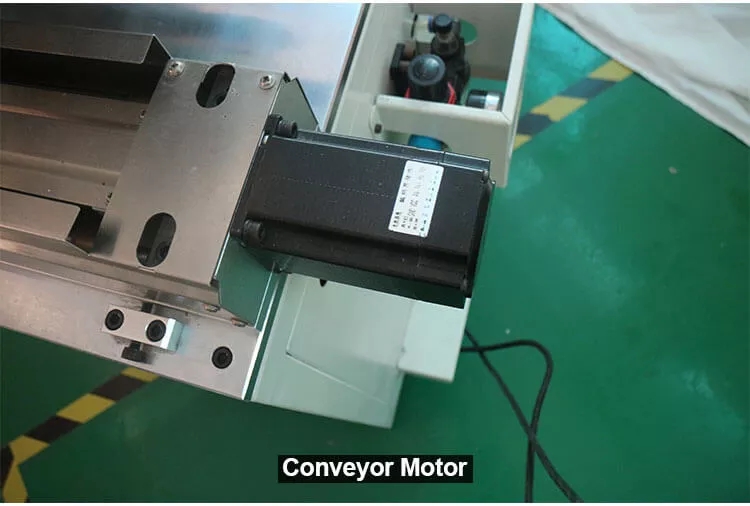

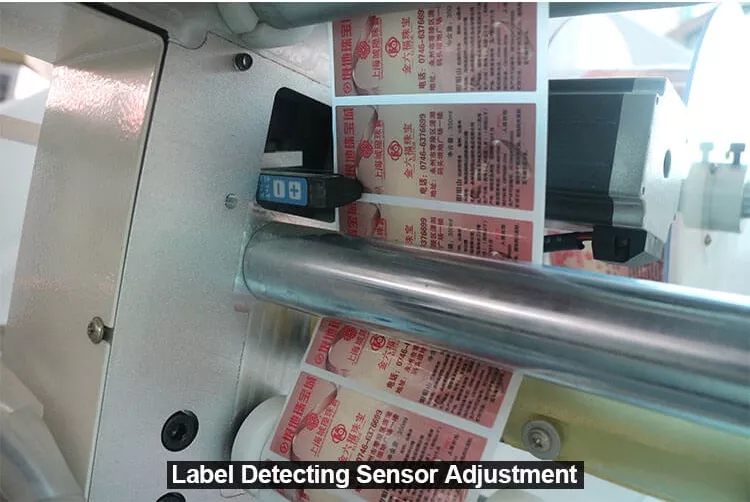

Accurate labeling: PLC+ fine-stepping-motor-driven label delivering ensures high stability and accurate label delivery; the feeding mechanism is equipped with brake function to ensure tensing the label strip and accurate detection of label positioning; The label strip rounding rectifier can prevent left or right offset of labels;

Durable: electric circuit and gas path are separately arranged; gas path is equipped with a purifying device to avoid air moisture fromdamaging electrical equipment, thus extending service life of theequipment; the device is made of advanced aluminum alloy and stainless steel, delivering superior quality and rugged reliability;

Easy to adjust: its vertical stroke is adjustable, so it is applicable for labeling products of varied heights, without the necessity to change fixtures repeatedly;

Beautiful appearance: the combination of bottom-placed computer, white distribution box, stainless steel and advanced aluminum alloy delivers aesthetic impression and improves the grade of the device;

Manual / automatic labeling is optional: operators can control the labeling by the sensor or by stamping;manual and automatic control buttons are provided; length of labels can be adjusted at will;

Application

This machine can fold and label wire products; such as electric wires, cables, optical fibers, data cables, power cables, candy bars, jelly, rubber hoses, hoses, braided tubes etc, stick a self-adhesive label folded in half.

Process of labeling

Only need to put the wire into the mold of the labeling machine to fix it, and the equipment will automatically send out the label to achieve half-fold labeling. The accuracy is plus or minus 0.3mm. The efficiency of labeling is greatly improved, which is 3 times that of manual labeling.

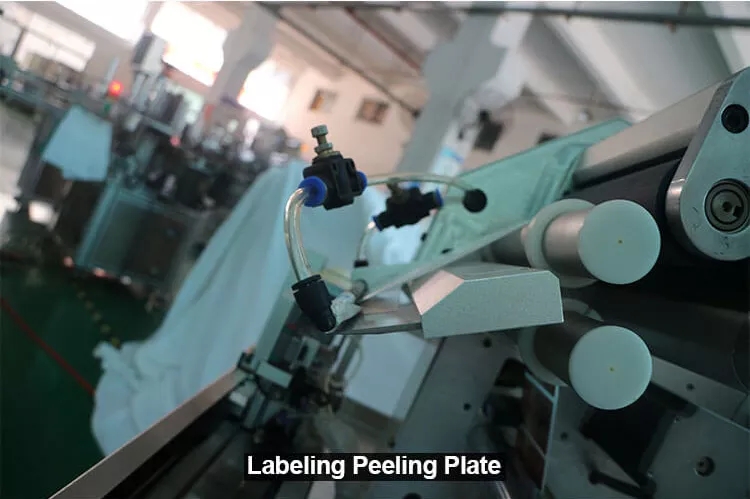

Start the equipment–peel off the label from the equipment–send the label to the label-absorbing board–manually put the wires on the clamping position–automatically align and fold the wire and the label-absorbing plate–automatically align the label–manually off the assembly line.

Control system

Principle description: Labeling machine is based on PLC as the core, receiving signals and controlling the work of all systems. When stepping the pedal switch, the signal will be sent to the PLC and processed according to a set of programs. Then complete the processes of stripping label and feeding label by starting on the stepper motor control system. At the same time, the label position sensor (also known as electric eye) will always pay attention to the distance by the label going through. When a label goes through, the sensor will send the signal to PLC immediately. Then the PLC, according to a set of programs, sends the signal to stepper motor control system to stop and starts on the labeling system so as to complete the process of labeling.