Introduction

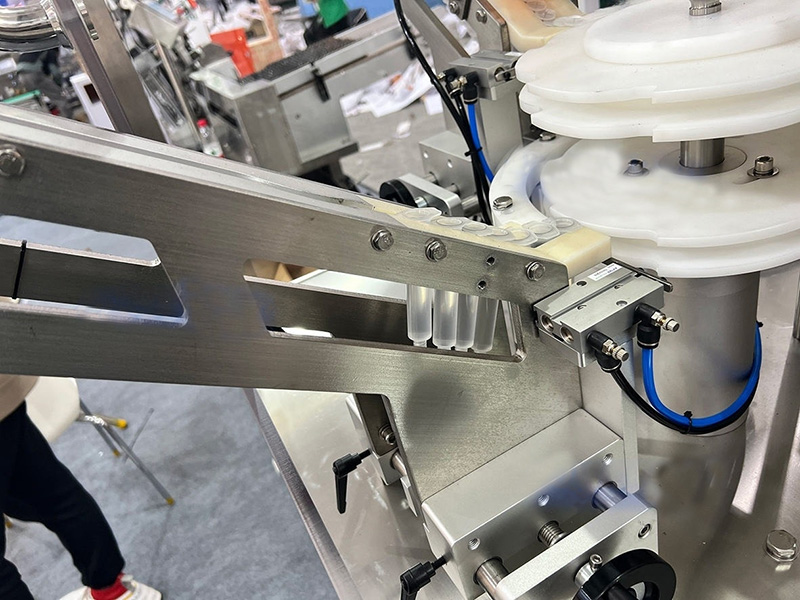

The syringe labeller is mainly applicable to the automatic rod screwing and labeling after the filling and sealing hammer of the pre filled syringe. The push rod and the needle tube are transferred to the rod screwing station through the double-layer star wheel. They are arranged concentrically from top to bottom through the fixture of corresponding size. The combined cam mechanism realizes the torque rod screwing between the needle tube and the push rod.

Then turn to the labeling station for labeling, and the stable speed of the whole machine is 160-200 pcs/min.

Note: VKPAK has experience in the custom design of high-speed syringe labeling machines. It can customize equipment according to customer needs, and can choose thermal printing, coding, visual inspection and other functions.

View VideoFeatures

1. High labeling accuracy, servo motor driven label sending, accurate label sending; The design of the deviation correction mechanism for the label belt to ensure that there is no left-right deviation in the process of label traction; The eccentric wheel technology is applied to the traction mechanism. The traction label does not slip, ensuring accurate marking;

2.It is firm and durable. It adopts a three-bar adjustment mechanism to make full use of the stability of the triangle. The whole machine is firm and durable;

3.Universal casters are installed on the equipment base, which is easy to move; The position display is installed on the adjustment parts, which can be adjusted in one step when replacing the product;

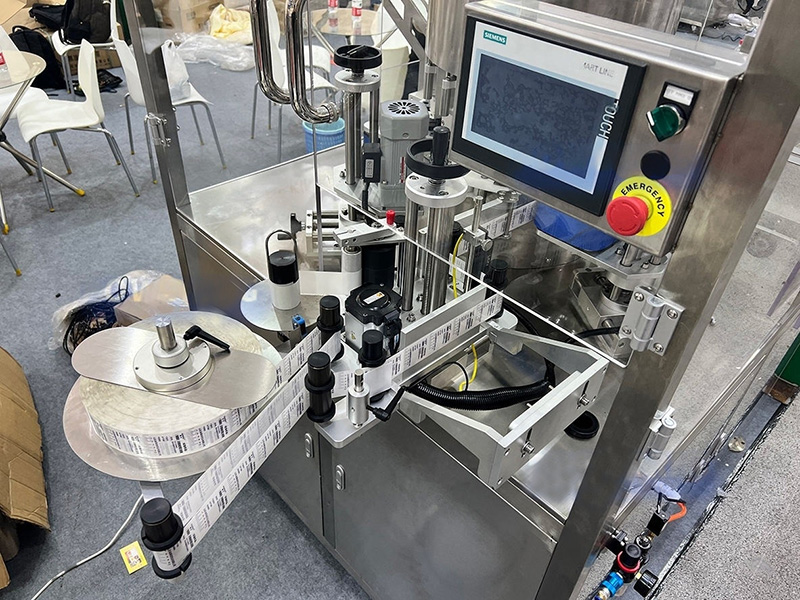

4.High stability, advanced electric control system composed of Siemens PLC, Siemens touch screen and servo motor, supporting equipment 7 × 24-hour operation;

5.Flexible application, single machine production or assembly line production, simple production site layout

6.Intelligent control, automatic photoelectric tracking, with no labeling, no labeling automatic correction and label automatic detection functions to prevent missing labeling and label waste;

7.Touch screen operation interface, full Chinese/English annotation and perfect fault prompt function, simple and fast adjustment of various parameters and convenient operation;

8.Powerful function, with production counting function, power saving function, production number setting prompt function, parameter setting protection function, convenient production management;

9.Optional configuration function:

※ hot code printing / ink-jetting function;

※ automatic feeding function, the storage capacity is large, the hoist feeds the material to the centrifugal disc, and the slide is used for unloading (considering the product);

※ automatic material collecting function (considering the product);

※ multiple labeling device;

※ other functions (customized according to customer requirements).

Parameter

| Voltage | AC220V 50/60HZ |

| Power | 4500W |

| Speed | 180pcs/min(Adjustable speed, actual speed depends on the object size and label length) |

| Accuracy | +1mm(depends on object characteristics) |

| Object size (optional delivery) | L(conveyor direction)100-2800mm |

| W(conveyor width)100-500mm | |

| H 1000mm~~2600mm(can be customized) | |

| Label | H:10mm~~80mm L: 20~~70mm(can be customized) |

| Inner diameter of label roll | Φ76mm |

| Outer diameter of label roll | Φ320 (max) |

| Weight | 400KG |

| Package size | 1500X1300X2000mm |

| Conveyor belt | (customize according to the site size) |

Application

Machine Details

Advantages

A syringe labeling machine is a precision-engineered equipment specifically designed to handle the unique requirements of labeling syringe products. These machines offer a highly automated solution for applying labels on syringes used in pharmaceutical, medical, and laboratory applications. The labeling process ensures clear and accurate labeling, enabling proper identification of syringe contents, dosage information, expiration dates, and other essential details.

In the pharmaceutical industry, accurate and efficient labeling of syringes plays a crucial role in ensuring product integrity and regulatory compliance. A high-speed syringe labeling machine offers a cutting-edge solution that enables rapid and precise label application, maximizing productivity on the production line.

Unparalleled Labeling Speed:

A high-speed syringe labeling machine is designed to handle the demands of high-volume production. It operates at exceptional speeds, allowing for rapid label application without compromising accuracy. With its high-speed capabilities, this machine significantly reduces labeling cycle times, ensuring maximum throughput and minimizing production bottlenecks.

Precision Label Placement:

Accurate label placement is vital for ensuring legibility and maintaining product aesthetics. A high-speed syringe labeling machine employs advanced precision labeling technology, which guarantees precise and consistent label placement on syringe bodies or caps. This eliminates label misalignment issues and enhances overall product quality.

Versatility and Adaptability:

To cater to diverse labeling requirements, a high-speed syringe labeling machine offers versatility and adaptability. It can accommodate various label types, including wrap-around labels, front and back labels, or spot labels. Additionally, the machine can handle different syringe sizes, allowing for seamless integration into existing production lines.

Advanced Control Systems:

High-speed syringe labeling machines are equipped with advanced control systems that provide real-time monitoring and precise label positioning control. Operators can easily adjust label parameters, such as position, orientation, and size, ensuring accurate label placement. This level of control enhances operational efficiency and minimizes label wastage.

User-Friendly Interface:

Efficient machine operation is facilitated by a user-friendly interface. High-speed syringe labeling machines feature intuitive controls and an easy-to-navigate interface, simplifying machine setup, operation, and troubleshooting. This user-centric design minimizes training requirements and maximizes productivity on the production floor.

Enhanced Productivity and Efficiency:

By automating the syringe labeling process, high-speed syringe labeling machines eliminate the need for manual labor, reducing human errors and increasing overall productivity. These machines can seamlessly integrate with other production line equipment, such as syringe filling machines or packaging systems, creating a streamlined and efficient labeling process.